Reduce equipment loss titanium carbide round rods

titanium carbide round bars can be customised with different properties by adjusting the titanium carbide content (usually 70-90%) and binder ratio. When the titanium carbide content is higher, it is more wear-resistant and suitable for roughing scenarios; an increase in the binder ratio improves toughness and makes it more suitable for finishing. Its density is only 6.5g/cm³, 20% lighter than tungsten carbide rods of the same size, making it suitable for making lightweight tools. In the 3C electronics industry, it is commonly used to process precision parts such as mobile middle frames and laptop shells, which can ensure that the product surface is free of scratches and small dimensional errors.

在线联系供应商

Other supplier products

| Widely used in cutting tools/molds/shaft parts Carbide rods | titanium carbide round bar is a high-performance bar made by powder metallurgy process, with titanium carbide as the main hard phase and cobalt or ... | |

| Stable and reliable titanium carbide hard alloy round bars | The production process of this round bar is extremely strict, from the purity control of titanium carbide powder (purity ≥99.5%) to the precise ... | |

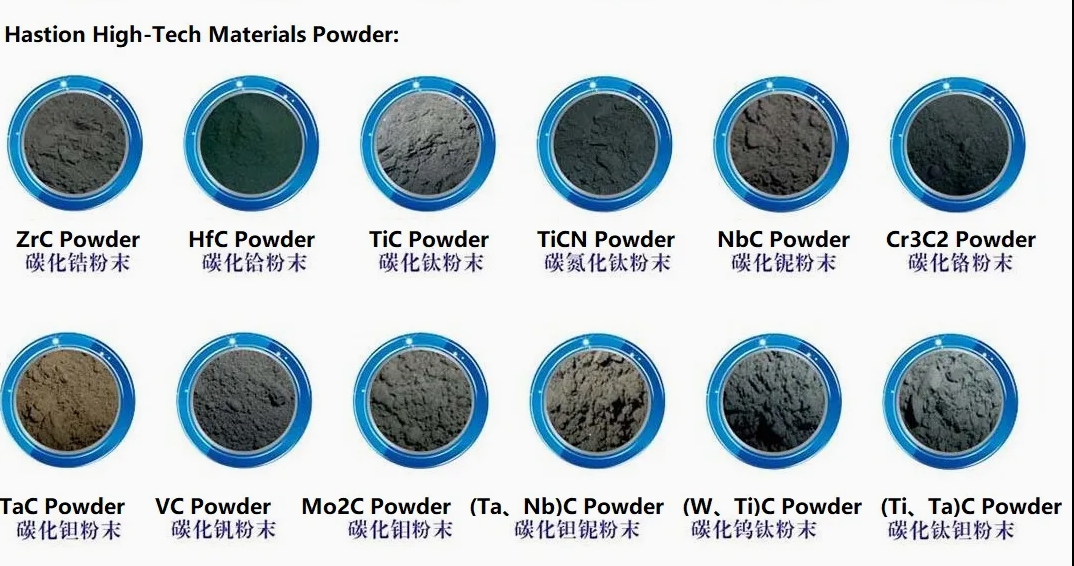

| Support particle size, purity and precise control of chromium carbide powder | Chromium carbide powder is often irregular grayish-black particles with a particle size of 10-40μm, a purity of ≥98%, and a free carbon conte... | |

| Factory direct supply cemented carbide round bar | Titanium carbide cermet rods (TiC rods) belong to the group of steel-jointed cemented carbides, which are composites of steel as the bonding phase ... | |

| Wear-resistant overlay chromium carbide powder | Chromium carbide powder is silver-grey to grey-black in colour, with fine and uniform particles, the particle size is mostly distributed in the m... |

Same products

| Anti-vibration wear titanium carbide hard alloy round bars | 卖方: 株洲华斯盛高科材料有限公司 | The production process of this round bar is highly stringent, encompassing every stage from the c... | |

| Stable and reliable titanium carbide hard alloy round bars | 卖方: 株洲华斯盛高科材料有限公司 | The production process of this round bar is extremely strict, from the purity control of titanium... | |

| Low-temperature resistant titanium carbide round bars | 卖方: 株洲华斯盛高科材料有限公司 | The anti-adhesion performance of tungsten carbide round rods made from hard alloy is highly effec... | |

| Scratch-free titanium carbide round rods | 卖方: 株洲华斯盛高科材料有限公司 | The anti-adhesion performance of titanium carbide round rods made of hard alloy is outstanding. W... | |

| High-gloss titanium carbide hard alloy round bars | 卖方: 株洲华斯盛高科材料有限公司 | As a key material in the high-end manufacturing field, hard alloy titanium carbide round rods hav... |