Silicone Rubber Prototyping

Silicone Rubber Prototyping

Our Silicone Rubber Prototypingservice offers fast, affordable production of flexible, durable prototypes. Ideal for testing and refining designs, Our liquid silicone rubber prototypingensure high-quality results with every project.

Key Features of Silicone Rubber Prototyping

Material Properties

Silicone rubber prototyping allows for the production of silicone prototypeswith unique material properties, including flexibility, elasticity, resilience, chemical resistance, and electrical insulation.

Design Flexibility

Silicone prototypes offer design flexibility, allowing for the production of complex geometries, undercuts, and intricate details in prototypes.

Versatility

Silicone rubber prototyping can be used for a wide range of applications, including medical devices, consumer products, automotive components, and more.

Material Options

Silicone rubber prototyping can utilize different types of silicone rubber materials, such as liquid silicone rubber (LSR) or high-consistency rubber (HCR), providing options for different hardness levels and material characteristics.

Fast Curing Time

Silicone keypad prototypecan be cured quickly, reducing the overall production time and allowing for rapid iteration and design changes.

Customization

Silicone rubber prototyping allows for the customization of prototypes to meet specific design requirements or client preferences.

Functional Testing

Silicone rubber prototypes can be used for functional testing, allowing engineers to evaluate the performance and functionality of the product before moving to mass production.

Visualization and Communication

Silicone rubber prototypes provide a tangible representation of the product, making it easier to visualize and communicate design concepts to stakeholders, clients, or investors.

Reduced Risk

Silicone prototype helps mitigate the risk of costly errors or design flaws by allowing for early identification and resolution of issues before investing in mass production.

Integration of Features

Silicone rubber prototyping enables the integration of features such as inserts, threads, or other functional elements directly into the prototype, providing a more realistic representation of the final product.

Quality Control

Silicone rubber prototypes can be used for quality control purposes, allowing for the evaluation of dimensional accuracy, surface finish, and other critical aspects of the product.

Time and Resource Savings

Silicone rubber prototyping eliminates the need for expensive tooling or molds required in traditional manufacturing methods, saving time and resources during the prototyping stage.

Scalability

Silicone rubber prototyping can be easily scaled up or down to meet different prototyping needs, from low-volume to high-volume production.

Collaboration and Feedback

Silicone prototypes facilitate collaboration and feedback from various stakeholders, including designers, engineers, and end-users, leading to improved product development and customer satisfaction.

Cost Estimation

Silicone rubber prototypes can be used for cost estimation purposes, providing insights into the manufacturing costs of the final product and helping with budgeting and pricing decisions.

The Basics of Silicone Rubber Prototyping

Silicone Rubber Prototyping involves creating prototypes from flexible, durable silicone rubber. It's a fast, affordable way to produce prototypes for testing and refining designs.

If you want to know more about precision machining definition, please visit our website.

在线联系供应商

Other supplier products

| Metal Rapid Prototyping | Our Metal Rapid Prototyping service provides fast, accurate, and affordable metal prototypes. Ourmetal printing prototypingservices use advanced te... | |

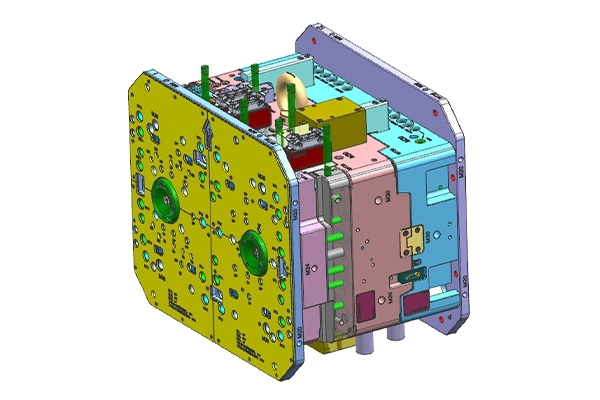

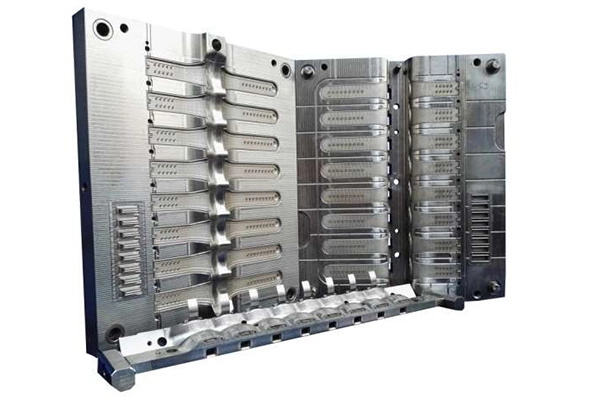

| Mold Design & Engineering | Quality Mold Starts from Excellent Design At YWX mold design company, mold design factory, our experienced designers play a crucial role in ensu... | |

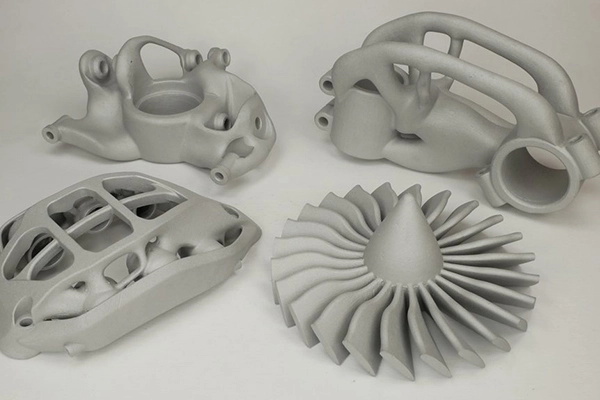

| Plastic Rapid Prototyping | Plastic Rapid Prototyping YWX as one ofrapid prototyping companies, offer plastic prototyping services, allowing for quick, cost-effective product... | |

| Silicone Injection Molding | Silicone Injection Molding Our silicone injection molding servicesoffer durable, flexible, and heat-resistant products. Ideal for a variety of app... | |

| YWX Molding Services | YWX Molding Services YWX custom molding services, specializes in injection molding with a wide range of capabilities. With a total of 10 sets of i... |

Same products

| Open Cooling Tower | 卖方: CHT TECK CO., LTD | Open Cooling Tower Design Features:A. Induced Draft Counter Flow Modular DesignB. Induced Draft ... | |

| Multi-Stage Refrigeration Canned Motor Pump | 卖方: CHT TECK CO., LTD | Multi-Stage Refrigeration Canned Motor Pump The refrigeration canned motor pump is a combination... | |

| Closed Circuit Cooling Tower | 卖方: CHT TECK CO., LTD | Closed Circuit Cooling Tower CHT TECK Cross Flow Type Closed Circuit Cooling Tower CHT TECK bra... | |

| EFDC Series Forced Draft Centrifugal Fan Type Evaporative Condenser | 卖方: CHT TECK CO., LTD | EFDC Series Forced Draft Centrifugal Fan Type Evaporative Condenser EFDC Series Centrifugal Fan ... | |

| Professional Titanium Alloy Click Pen Ballpoint PenOutdoor Survival Tools | 卖方: 854584 |