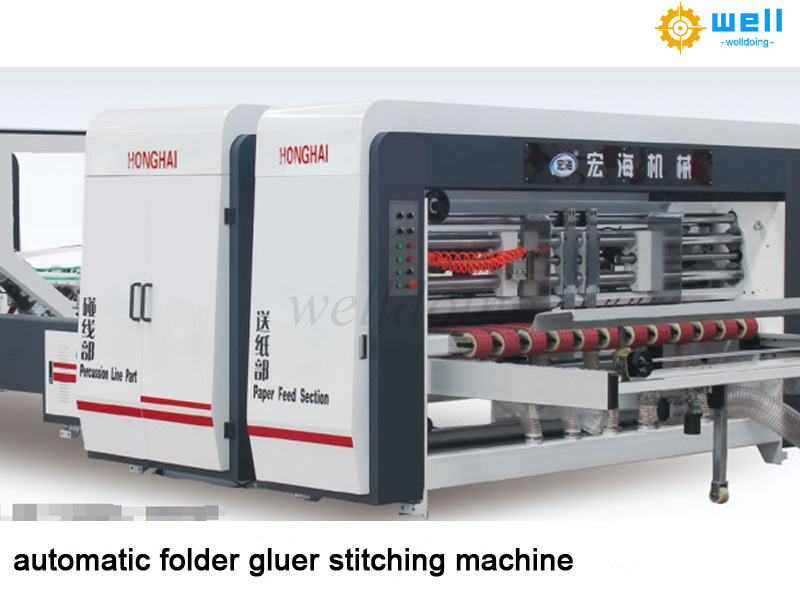

automatic carton box folder gluer stitching machinery

is composed of six parts: paper feeding part, line touching part, folding part, nailing box part, counting output part and electrical control part. PLC control touch screen input data, nail box part action servo motor control, simple and reliable operation. Automatic feeding, automatic line, automatic folding, automatic correction, automatic nailing, automatic counting, automatic stacking output, before and after the whole machine, synchronous adjustment, order storage, difference between sticky box machine and nail box insufficiency work units installed, host nail stick up and down automatically, a key transformation, transverse, nail stick work independently, when the adjustment more convenient, fast and efficient. Advanced technology, reliable quality.

A. Paper feeding department:

Adopt SiGreen high wear-resistant suction belt, each can control the size of the air volume separately. To ensure the stability of adsorption, the machine adopts pneumatic buffer plastic shaft feeding method to effectivelysolve the problemof low compression resistance of cardboard with line, the paper feeding part adopts double drive servo separation before and after the paper feeding, while thepreloading synchronous automatic adjustment, each cardboard before and after individual precise transmission, more accurate positioning.The front baffle of the feeding part can be adjusted by electric power, and the front feeding part can be adjusted byelectric power. It is convenient and fast to meet the demand of paper supply of various specifications.

B. Wire touching part:

Thepaperboard is sent from thepaper feedingdepartment to theline touching department.Itis a feature ofour company's.The originalpaperboardis often not ideal after thepreviousprocess,whichaffectsthequalityofproducts.Theline touching partis to deal with the originalrollingpart by the method oflinetouching again, so asto achieve a better folding effect,and can wellcontrolthe size of the carton after sticking nails.The keydata is obtained from countless tests and tests.The pressure of theline touching can be adjusted according tothe thickness and materialofthe paperboard. Therefore,theline touchingpart has the advantagesof reasonable structure,novel design, practical convenience and obvious effect.

C. Folding part:

Linkage with the paper feeding part, frequencyconversion speedregulation, folding and paper feeding partpressline synchronous adjustment. Imported porous beltconveyor cardboard, automaticfolding,the whole process of adsorption,effectively avoid weight box, film box, glazing box and other cardboard in the work of the phenomenon of skew skid pile of paper, make the machine more stable and efficient.

D.Calibration Department

1. Thehas a shapingdevice before the nailingbox attheback ofthe foldingpart.Before the nailingbox,thefoldedcartons willbe adjusted and patted againto ensure that the nailedcartons have no scissors.

2.The calibrationpartisdriven byservo motor.

E. department:

1.Interconnect with theline touching part,frequency conversion speed regulation, add each molding wheel. roll the originalline acain

2.The machine is characterized by direct drive of servo motor with stable and accurate speed.

3. The stitchinglineadopts 2plates of2kgflat wire automatic wire feedingdevice to reduce the number of wire changingandimproveproductionefficiency.

4 This machine can beused for single nail,double nail,strengthen the multi-functionoperation of the carton.

5 nailspeedper minute upto 700 nails/minute.

|

Model |

QDJ-2600H+(No beat) |

QDJ-2600H+(beat) |

|

MAX (A+B) *2(mm) |

2400(stick)2600(nail) |

2600 |

|

MIN (A+B) *2(mm) |

780 |

1060 |

|

MAX (C+D+C) (mm) |

1200 |

1200 |

|

MIN (C+D+C) (mm) |

340 |

530 |

|

MIN rock cover C (mm) |

25 |

25 |

|

MAX rock cover C (mm) |

320 |

320 |

|

MAX width B (mm) |

500 |

500 |

|

MIN width B (mm) |

165(nail)140(stick) |

250 |

|

MAX length A (mm) |

800 |

800 |

|

MIN length A (mm) |

260 |

280 |

|

MAX height D (mm) |

650 |

650 |

|

MIN height D (mm) |

200 |

200 |

|

width of the tongue E (mm) |

30-35 |

30-35 |

|

length (mm) |

15000 |

1500 |

|

width (mm) |

3700 |

3700 |

|

power (kw) |

22 |

22 |

|

Weight(T) |

11 |

11 |

|

Stitching Speed(Nail/min) |

1000 |

1000 |

|

Number of Nails |

1-99 |

1-99 |

|

Nailing From(mm) |

30-80 |

30-80 |

|

Nailing speed (Tablets/min) |

100-110 |

80-100 |

|

Sticky box speed(M/min) |

110 |

110 |

F. Counting and stacking output

Completethe carton,clap,count,stack and send out the whole dozenautomatically.

1. OEM service are available.

2. Trade Manager online, also contact by Email.

3. To solve problems by pictures/videos.

4. Engineers are available service abroad.

FAQ

1. Are you a factory or trading company?

We are both a factory and a trading company in this field .

2. What is the terms of payment you accept?

We usually accept the T/T payment, we need 30% of total amount as deposit,

pay the 70% balance before delivery, but we can also accept the L/C.

3. How does your factory do regarding quality control?

Quality is priority. We always regard great importance to quality controlling fromthe very small thing(even a small screw we will choose the best quality) from thebeginning.

If you are also interested in this machine,please don’t hesitate to contact us:

Overseas manager: Tom Wang

在线联系供应商

Other supplier products

| corrugated carton 1-4 color printer die cutter slotter machine | Paper feeding section (one group) 1. Machine clutch: 1) An alarm bell is attached to the clutch of the electric control machine, and the alarm be... | |

| 1400 mm industrial paper automatic hardboard production line | The1400 mm industrial paper hardboard production lineis suitable for combining 80-600g / m2 grey board with 2,3 and 5 layers with the required thic... | |

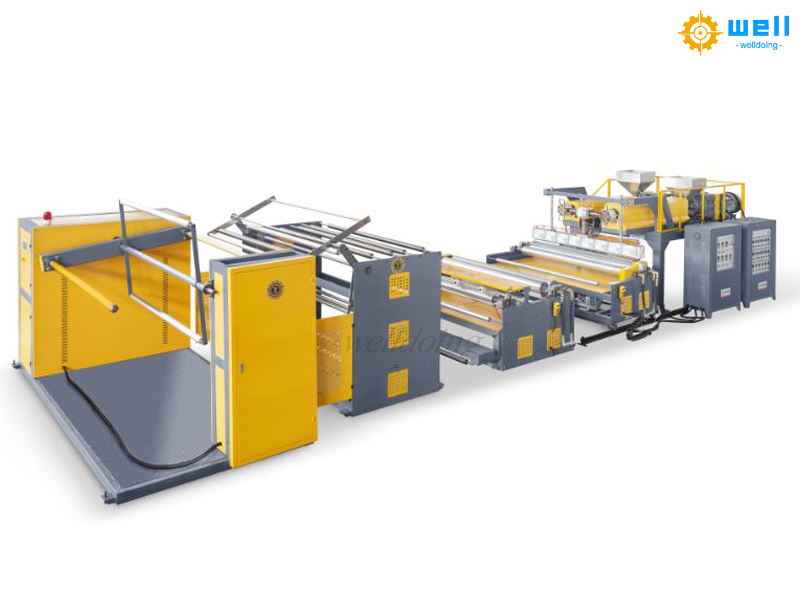

| Automatic Plastic Air bubble film making machine | The machine is mainly composed of extruder, die head, vacuum negative pressure system, bubble forming die, traction mechanism, rolling mechanism,... | |

| Paper Hardboard Production Line | Cardboard Composite | TheCardboard composite production lineis suitable for combining 80-600g / m2 grey board with 2,3 and 5 layers with the required thickness and speci... | |

| Sewage water treatment machinery for printing machine | waste water treatment machinefeatures: 1.Our ink sewage treatment equipment with novel design, advanced processing technology, fully consider for ... |

Same products

| 中国供应商 饮料厂用全自动玻璃瓶果汁液体灌装机 | 卖方: 河北盛辉泵业 | 饮料液体灌装机具有集水处理、清洗、灌装、贴标和封盖于一体的自动化机身,是精确、快速灌装稀薄至中等粘度液体的理想选择。它拥有完善的温度控制系统、自动清洗系统、精确的温度控制系统和逆流系统。 | |

| 中国供应商出厂价 500 毫升矿泉水瓶液体灌装机 | 卖方: 河北盛辉泵业 | 该机采用先进的生产工艺,结构科学合理,操作简便。广泛应用于矿泉水、茶、果汁等饮料的塑料瓶和玻璃瓶灌装。也是饮料生产厂和矿泉水生产线的理想选择。同时,它还可与旋盖机、贴标机配套组成流水线。 | |

| 受欢迎的卧式半自动高粘度液体酱料灌装机 | 卖方: 河北盛辉泵业 | 半自动膏体灌装机适用于各种粘性、非粘性、腐蚀性液体及其它小包装的定量灌装。该机由卧式半自动灌装机和小型输送带组成,有利于瓶装灌装液体的有效输送,节省人力。它具有结构合理、操作方便、智能控制等优点。 | |

| 高性能立式自动小袋棒状粉末液体包装机 | 卖方: 河北盛辉泵业 | 粉末液体灌装机装机适用于各类流动性差的酱体包装,配备三边封或四边封制袋成型及精确定位封切系统,可通过活塞行程方式调节,达到精确控制流量,自动计量和自动灌装的目的。适用于粘稠体、悬浮液和乳化油等流... | |

| 新产品全自动无菌BIB盒中袋液体灌装包装机 | 卖方: 河北盛辉泵业 | 无菌袋灌装机是专门针对盒中袋定量灌装作业而设计的,采用流量计自动控制每次出料量,灌装精度高,灌装量设定、调节动作直观、简便。该设备设计新颖,结构合理紧凑,能自动完成开盖、定量灌装、抽真空、封盖等... |