Automatic 55 Gallon Drum washer, 200L Barrel Cleaning Solution

Features:

This semi-automatic200 liters barrel cleaning systemutilizes our rotary impingement technology and is designed to blast stubborn residuesfrom the barrel & drumin the fields of solid waste treatment, chemical industry, pharmaceutical, new energy industry, personal care and etc.. It is able to clean residuesinside of the barrel in a precise and global indexing pattern.The whole cleaning operation is completed by this automatic machine and you just need the operator to monitor and control the entire cleaning process, providing some auxiliary operations if necessary.

We guaranteed that the cleaning technology ensures the entirebarrelis thoroughly cleaned in the most efficient manner, utilizing the least amount of resources including time, energy, and cleaning fluid.Thebarrel washer comes equipped with everything you need to set up a barrelcleaning system, coming with low or high pressure cleaning nozzles according to your application.

Structure:

High Pressure Pump System

Excellent water supply capacity ensures efficient operation of the barrel cleaning system.

Barrel Cleaning Working Position

A programmable logic controller(PLC) operates all of the machine functions during wash cycles to realize barrel automatic cleaning operation. This working position is designed with many structures including but not limited induction group, barrel holder and tightening handle, high pressure rotary cleaning machine, automatic barrel tilting mechanism and so on.

Drum Cleaning Technology Description:

Operation demonstration: Align the cleaning nozzle and put it into the bucket to be cleaned. There will be fixed jackets on both sides to fix the bucketbody. And the cleaning cycel time is 2-4 minutes (the time can be adjusted according to the situation), and operating pressure can be adjusted from 3-150 bar.

Two modes can be adjusted according to the cleaning situation:

1. Low pressure cleaning modes, 3-20 bar pressure.

2. High-pressure cleaning modes, 80-150 bar pressure

3. Hot water detergent low pressure mode, this mode is aimed at oily barrels, first spray with detergent and then wash with 10-20 bar pressure.

4. Hot water detergent high pressure mode, this mode is aimed at petrolatum barrels, first spray with detergent and then clean with 150 bar hot water and clean water, liquid temperature is 40-50 degrees

Benefits of Barrel Washer:

Fast: Clean any barrelin2-4 minutes

Clean the entire drum, including the top and corners

Powerful: Clean a variety of residues

Affordable: A fraction of the cost of CIP tank cleaning systems

Residues:

Any and all including:

Paints, adhesives, chemicals

Petroleum products

Food and beverages products and ingredients

Pharmaceutical products and ingredients

Personal care products and ingredients products

And many more.

Common Application:

In all industries:

barrel

drum

vats

buckets

在线联系供应商

Other supplier products

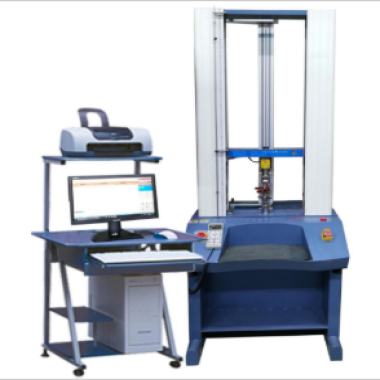

| Rubbing Color Fastness Tester | Introduction Manual friction fastness tester is the most commonly used instrument for the textile industry to detect the color fastness of the... | |

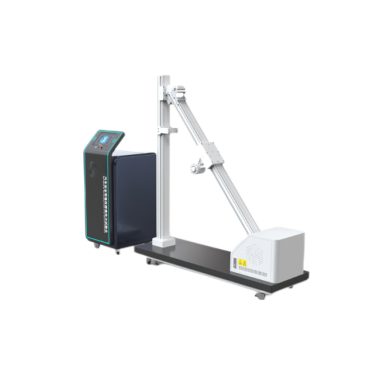

| Car seat foam performance tester | Applicable standards: GB/T 6670-2008"Determination of falling ball resilience of soft foam polymeric materials" : This standard specifies the test... | |

| Automotive Wire Adhesion Tester | Standard Engineered to meet the rigorous demands of global automotive and adhesives industries, our Automotive Wire Adhesion Tester strictly adh... | |

| Vapor Shrinkage Tester | I. Product Overview TheVapor Shrinkage Testeris a specialized thermal analysis instrument designed to measure dimensional changes in textiles, pol... | |

| Safety Helmet Electrical Insulation Tester | Product Introduction: Safety hat electrical insulation performance tester used to test the electrical insulation performance of safety hat, high d... |

Same products

| Seat Bumping and Creep Test Bench | 卖方: Standard International Group (HK) Limited | This test bench is used for simulating the car seat bumping and creep situation when a car is run... | |

| Automobile seat belt fixed point test bench | 卖方: Standard International Group (HK) Limited | Applicable standards: National mandatory standards: GB 15083-2006"Automobile seats, seat fixtur... | |

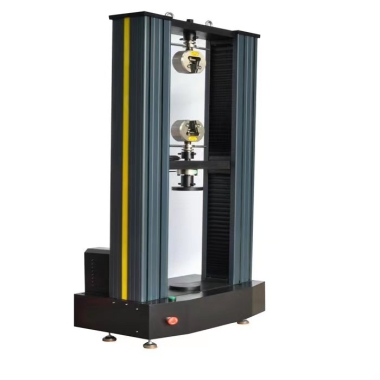

| Impact strength tester for car seat headrest | 卖方: Standard International Group (HK) Limited | Applicable standards: GB 15083-2006 "Automobile seats, seat fixtures and headrest strength requi... | |

| Impact strength tester for car seat launching headrest | 卖方: Standard International Group (HK) Limited | Main parameters: Impact speed:The impact speed of the tester is usually between 25 and 30km/h, w... | |

| Automobile Headrest Strength Tester | 卖方: Standard International Group (HK) Limited | Applicable standards: GB 11550-2009"Automobile seat headrest strength requirements and test me... |