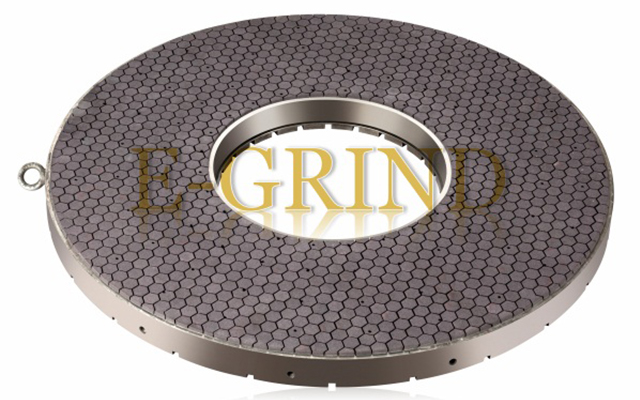

Vitrified Bond Grinding Wheels

Vitrified bond grinding wheelsare abrasive tools used for precision grinding across a range of industries. They are composed of abrasive grains, such as alumina or silicon carbide, held together by a vitrified (ceramic) bond. The vitrified bond provides durability, strength, and resistance to heat.

E-grind Vitrified bond grinding wheels are made in both Diamond and CBN, allowing for customization based on the specific needs of the application. The diamond and CBN are held in place by ceramic components that are fused to form the abrasive part of vitrified bond grinding wheels. The Vitrified diamond and CBN grinding wheels offer high grinding efficiency and excellent wheel shape retention. The inherent durability and thermal stability of vitrified grinding wheelsmake them essential tools for grinding applications that demand precision and consistency.

How are vitrified grinding wheels made?

E grindVitrified bond grinding wheels are made from abrasives(conventional abrasives, diamond powder, CBN powder), pore-forming agents, ceramic powder, and body(aluminum, steel, ceramic, etc).

Abrasives, pore-forming agents, and ceramic powder will be pressed and sintered into an abrasive ring first, then stuck on a body.

FAQs of Vitrified Bond Grinding Wheels

What is vitrified bond in grinding?

The vitrified bond is the type of bonding agent in grinding wheel, generally, ceramic powder or glass powder. Vitrified bond has better chemical stability, higher bonding strength, and excellent sharpness.

What are the advantages of vitrified bonding?

Vitrified bonding offers several advantages, including high thermal stability, excellent hardness, and the ability to customize compositions. The vitrified bond grinding wheels contribute to prolonged wheel life, precise grinding, and efficient coolant delivery.

Which industries can use Vitrified Bond grinding wheels?

Vitrified Bond grinding wheels find applications in a variety of industries, including metalworking, woodworking, ceramics, glass, aerospace, automotive, and more. They are versatile tools suitable for precision grinding tasks across different materials.

What is the difference between resin bonded and vitrified bonds?

The main differences lie in the bonding agents. Vitrified bonds use a ceramic (vitrified) matrix, offering high hardness and thermal stability, while resin-bonded wheels use a resin matrix, providing flexibility but with lower heat resistance. Vitrified bonds are more suitable for precision and high-temperature applications.

How do you maintain Vitrified Diamond & CBN grinding wheels?

Maintenance involves proper dressing and truing of the wheels to maintain their profile and sharpness. Additionally, using coolants as recommended for specific applications helps manage heat. Inspecting the wheels for damage and addressing any issues promptly is crucial for optimal performance.

What is the average cost of Vitrified Diamond & CBN grinding wheels?

The cost of Vitrified Diamond & CBN grinding wheels can vary based on factors such as size, specifications. You're welcomed to contact E-grind at for accurate pricing. Receive prompt, precise, and competitive pricing by reaching out to us today.

There are many cbn grinding wheel suppliers, but we are one of the best choices for you.

在线联系供应商

Other supplier products

| Crankshaft, Camshaft & Cylindrical Grinding Wheels | E-Grind provides vitrified bond CBN wheels for grinding automobile camshafts, crankshafts, and cylinders in the air-compressor industry. Optimum bo... | |

| Double Disc Grinding Wheels | Vitrified bond Diamond/CBN double disc performs grinding and lapping in one process using a fixed abrasive system which makes cleaning the work pla... | |

| Diamond Dressing Roller | Vitrified grinding wheels with Silicon Carbide, Aluminum Oxide, Diamond, or CBN as grinding media lose their profile accuracy and cutting capacity ... | |

| Dicing Blade & Grinding Wheels For Semi-Conductor | Henan E-Grind Abrasives Co., Ltd can offer the semiconductor industry cutting-edge dicing blades & grinding wheels of the utmost quality. Diamo... | |

| Diamond Dressing Roller | Vitrified grinding wheels with Silicon Carbide, Aluminum Oxide, Diamond, or CBN as grinding media lose their profile accuracy and cutting capacity ... |

Same products

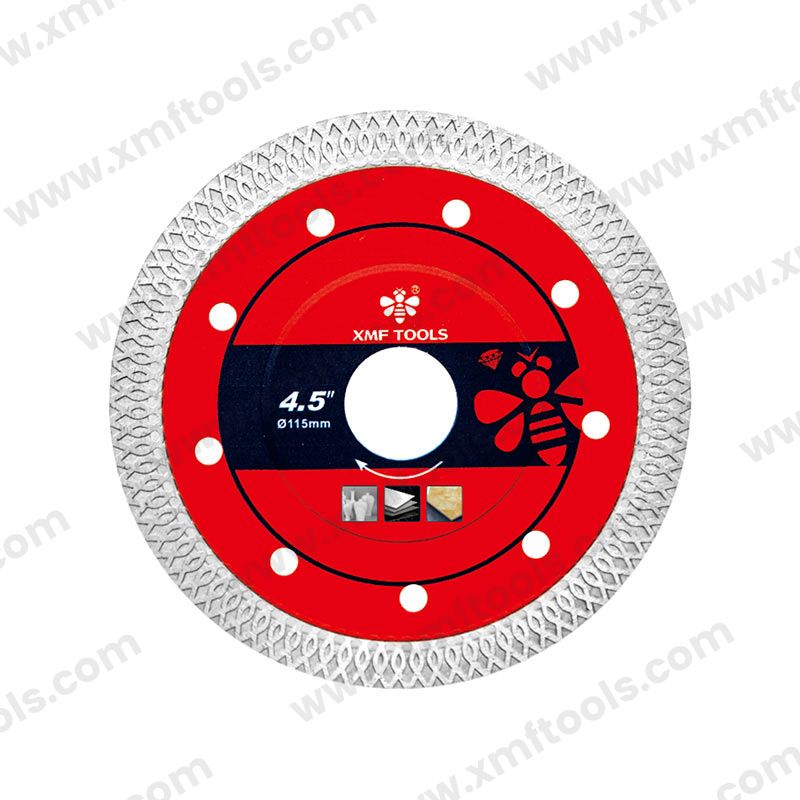

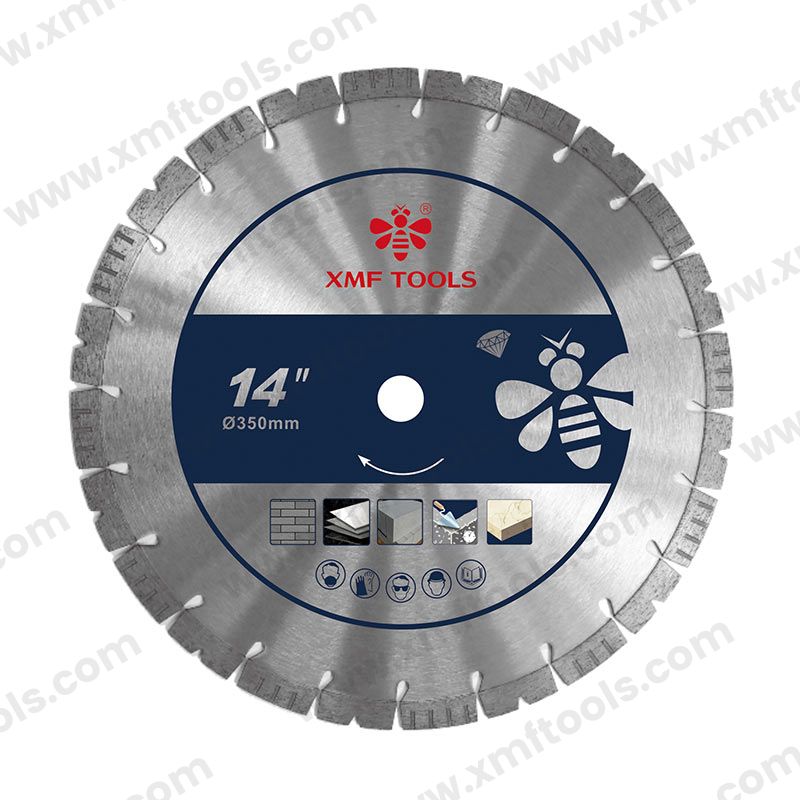

| Silent Normal Marble Saw Blade | 卖方: Hebei XMF Tools Group Co., Ltd | Marble Cutting Bladesare precision-engineered diamond blades designed specifically for clean, smo... | |

| Hot-Pressed Y-Turbo Saw Blade | 卖方: Hebei XMF Tools Group Co., Ltd | Hot-pressed diamond segments for enhanced durability and superior cutting performance Ultra-thin... | |

| Sintered Gp Saw Blade K | 卖方: Hebei XMF Tools Group Co., Ltd | Equipped with aggressive sintered segments that provide faster, smoother cuts through tough mater... | |

| Phonefix FX-08 耐高温刀片套装 | 卖方: 深圳维客修科技有限公司 | 产品描述 PHONEFIX 手工抛光一体式刀片采用一体式手柄设计,耐300℃高温手柄,使用方便,经久耐用。手工抛光,轻松撬出IC硬盘CPU脱层。5种形态,5种选择,全面覆盖各种维修场景。适用于撬... | |

| 2UUL 五合一 DA22 手工抛光刀片,用于 PCB 底部填充清洁 | 卖方: 深圳维客修科技有限公司 | 产品描述 2UUL DA22 手工抛光 QUICK 刀片五合一套装,适用于手机 PCB 底部填充清洁、CPU BGA 芯片分离和除胶。专业手机维修套装 - 2UUL DA22 五合一手工抛光刀片... |