liquid silicone rubber for molding make

Specification: -Two-parts, flowable liquid silicon & curing agent. -It gets cured at room temperature 250C within 3-5 hours. -An exceptional fluidity and good operability, easy to be demolded. -Good tensile strength and tear strength, low shrinkage. -Suitable for both brushing and pouring methods of operations for medium & large sized molds making. Application: Silicon rubber for PU/poly resin products, unsaturated resin products, plaster, candles and gypsums crafts, toys, soap, statuary, concrete casting molds making, etc.Datasheet: Model 628# Appearance white Mixing proportion of curing agent (%) 5% Operating time (mins 25 0C ) 30-50 Curing time(hours 25 0C) 3-5 Hardness (A°) 27~28 Density ( g/cm 3 ) 1.08 Viscosity (Mpas -25 0C) 27000~32000 Tensile-strength(kgf /cm2 ) ≥40 Tear-strength (kgf /cm ) ≥30 Elongation-break(%) ≥ 450 Retractility(%) ≤0.3Operation: 1,mix the silicone and catalyst with a ratio 3~4%, stir evenly, release the bubble. 2,pouring the silicone rubber into the frame. 3,after it cured , demould the silicone mold.More information , pls feel free to contact Mr Allen: e-mail: hyje(at) Tel: Mobile;在线联系供应商

Other supplier products

| screen silicone ink for silicon product | TB0330 is a 2-part liquid silicone with high transparency , great tear-strength and strong bonding force. Specification: -Low shrinkage(<0.1%) -Goo... | |

| liquid silicone rubber for molding make | Specification: -Two-parts, flowable liquid silicon & curing agent. -It gets cured at room temperature 250C within 3-5 hours. -An exceptional fluidi... | |

| high transpanrency silicon for label | Trademark silicone rubber SB0430 is room temperature addition-cured liquid molding silicone rubber with low viscosity,which has all kinds of the ... |

Same products

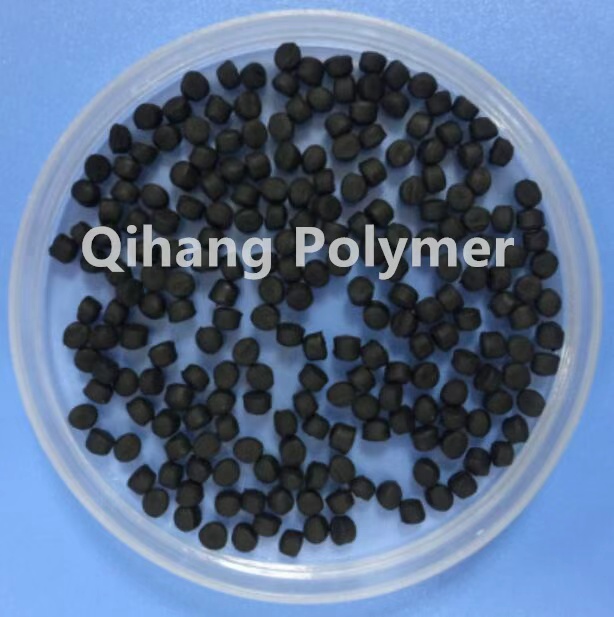

| Thermoplastic vulcanized rubber | 卖方: Jiangsu Qihang Polymer Technology Co.,Ltd. | We hold ISO9001, ROHSand REACH certifications, ensuring global compliance. Excellent weather res... | |

| thermoplastic elastomer tpe material 45A-50D | 卖方: Jiangsu Qihang Polymer Technology Co.,Ltd. | ||

| Iron Single Adjustable Cafe Rod Set | 卖方: Deqing Bochuang Hardware Co., Ltd | The Iron Single Adjustable Cafe Rod Setis a durable and stylish window treatment solution. Featur... | |

| Investment Cast Valve Body Component | 卖方: Qingtian Baoli Casting Co., Ltd. | TheInvestment Cast Valve Body Componentis developed for industrial valve systems requiring accura... | |

| PVC 糊树脂 | 卖方: 地址:天津市南开区三马路133号海豚大厦4层 | 树脂乳液型PVC树脂(人造革专用) 外观:白色粉末执行标准:GB/T5761-2006 包装规格: 20公斤/PP袋 1吨袋 或根据协商确定 重量: ... |