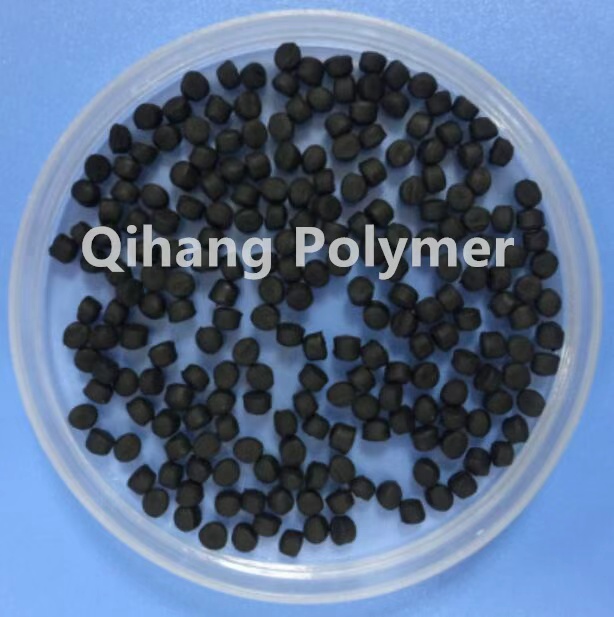

pad printing silicon rubber

Features of pad printing silicon rubber

Pad printing silicon rubber requires to be exquisite, without granules or impurity, and has advantages of wearability and resilience.

Applications of pad printing silicon rubber

Pad printing silicon rubber is specially designed for making printing pads . It is mainly used for printing irregular patterns of plastic toys, electroplating products, electronic toys, trademarks, etc.

Operation instruction for pad printing silicon

1. Wash and clean molds with detergents, dry the molds and use an air gun if necessary, and apply a film of mold release.

2. Determine the normal proportion of pad printing silicon and silicon oil on the basis of customer requirements. Add more silicon oils if a larger area of printed pattern and therefore soft rubber head is needed by the customer. Otherwise, add no or less silicon oil for better hardness. For normal pad printing rubber head, hardness between 15 A°--25A°will be appropriate. If excessive amount of silicon oil is added, the number of printing will be limited by an extremely soft rubber head, and the molecular weight of silicon of however supreme quality will be destroyed by silicon oil, and therefore, the phenomenon of compromised resistance to abrasion, solvent and aging.

3. The normal proportion is as follows: 100g silicon admixed with 30g silicon oil for a hardness of 20 A° will be

suitable for pad printing for alloy toy cars and products with small patterns and contact area. If larger pressure contact surface or soft rubber head is required, the silicon and silicon oil proportion can be adjusted to 100:50, 100:80 and so on. Remember, the more silicon oil is added, the softer the rubber head will be, and the number of pad printing, resistance to abrasion and solvent will be undermined, and hence, heightened cost and more material waste.

Any questions of silicone rubber, please feel free to contact Kity :

TEL:

kity920101(AT)

MSN: kityszrl (AT)hotmail (DOT)com

Other supplier products

|

|

Manual Molding Silicone Rubber |

Manual molding silicone rubber

1. Good elasticity

2. Non-deformation

3. Heat resistance

4. Low shrinkage

Applications of Manual Molding... |

|

|

pad printing silicon rubber |

Features of pad printing silicon rubber

Pad printing silicon rubber requires to be exquisite, without granules or impurity, and has advantages ... |

|

|

Silicone rubber for mold making |

Silicone rubber for mold making:

1. resistance to deformation

2. high reproduction times

3. good tensile strength

4. exceptional fluidity

... |

供应产品

Same products