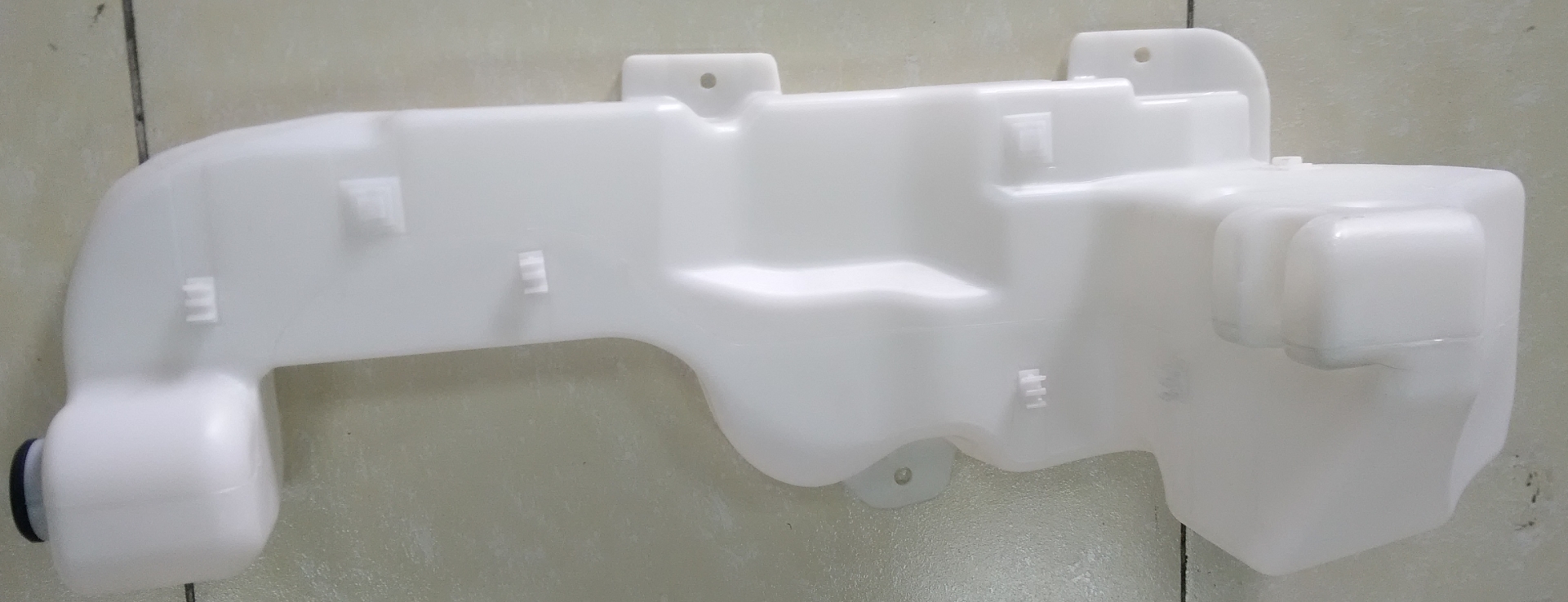

Blow molding;

Blow moldingis a manufacturing process by which hollowplasticparts are formed. In general, there are three main types of blow molding: extrusion blow molding, injection blow molding, and injection stretch blow molding. The blow molding process begins with melting down the plastic and forming it into aparisonor in the case of injection and injection stretch blow moulding (ISB) a preform. The parison is a tube-like piece of plastic with a hole in one end through which compressed air can pass.

The parison is then clamped into amoldand air is blown into it. The air pressure then pushes the plastic out to match the mold. Once the plastic has cooled and hardened the mold opens up and the part is ejected.

Tandem is using extrusionblow molding process, whichin Extrusion Blow Moulding (EBM), plastic is melted and extruded into a hollow tube (a parison). This parison is then captured by closing it into a cooled metal mold. Air is then blown into the parison, inflating it into the shape of the hollowbottle, container, or part. After the plastic has cooled sufficiently, the mold is opened and the part is ejected.Continuous and Intermittent are two variations of Extrusion Blow Molding. In Continuous Extrusion Blow Molding the parison is extruded continuously and the individual parts are cut off by a suitable knife. In Intermittentblow moldingthere are two processes: straight intermittent is similar to injection molding whereby the screw turns, then stops and pushes the melt out. With the accumulator method, an accumulator gathers melted plastic and when the previous mold has cooled and enough plastic has accumulated, a rod pushes the melted plastic and forms the parison. In this case the screw may turn continuously or intermittently. with continuous extrusion the weight of the parison drags the parison and makes calibrating the wall thickness difficult. The accumulator head or reciprocating screw methods use hydraulic systems to push the parison out quickly reducing the effect of the weight and allowing precise control over the wall thickness by adjusting the die gap with a parison programming device.

Tandem using blow molding process to produce a lot of items of kit box, bonsai pot, plastic pallet, etc.s since 2006.

在线联系供应商

Other supplier products

| Kit box | We're always facing rush hour in shopping stage when Father's Day andChristmas day is approaching. Open pack kit boxes will help us to save a lot o... | |

| Car Radiator | Acar radiator s a type ofheat exchanger.It is designed to transfer heat from the hot coolant that flows through it to the air blown through it by t... | |

| Plastic Model | 1.Item: Plastic mode; 2.Raw material: HDPE; 3.Manufacturing process: Blow Molding; 4.Events: Designers had consolidated with fitting model sizes an... | |

| Blow molding; | Blow moldingis a manufacturing process by which hollowplasticparts are formed. In general, there are three main types of blow molding: extrusion bl... | |

| Plastic Pallet | 1.Item: Plastic Pallet; 2.Raw material: HDPE; 3.Manufacturing process: Blow Molding; 4.Events: Hollow blow molding technology with progress of tech... |

Same products

| Iron Single Adjustable Cafe Rod Set | 卖方: Deqing Bochuang Hardware Co., Ltd | The Iron Single Adjustable Cafe Rod Setis a durable and stylish window treatment solution. Featur... | |

| Competitive Price OEM Waterproof Nylon Injection Molding Parts | 卖方: 河北二业橡塑制品有限公司 | Product Specification Description Products Name: Custom plastic and rubber parts Materials: Plast... | |

| Wholesale Plastic Injection Insert Molding Custom Plastic Parts | 卖方: 河北二业橡塑制品有限公司 | Product Specification Description Products Name: Custom plastic and rubber parts Materials: Pla... | |

| 塑料定制品 | 卖方: 河北二业橡塑制品有限公司 | Product Specification Description Products Name: Custom plastic and rubber parts Materials: Plast... | |

| z中国工厂定制塑料品 | 卖方: 河北二业橡塑制品有限公司 | Product Specification Description Products Name: Custom plastic and rubber parts Materials: Plast... |