Plastic Extrusion Line Manufacturer

Plastic Extrusion Line Manufacturer

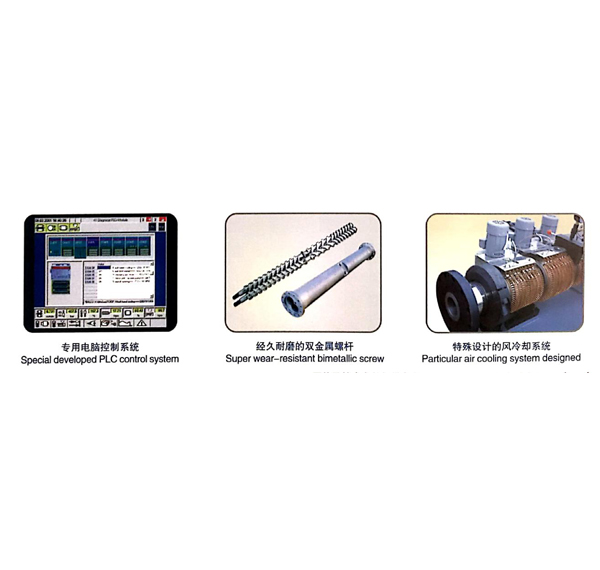

Plastic extrusion line, as the name implies, is a machinery and equipment specialized in the production of various plastic products, which belongs to a large category of plastic machinery and equipment. Common components are: automatic feeding and mixing system, extruder, die head, shaping cooling system, tractor, cutting device, winding device or stacker.

Types of Plastic Extrusion Line For Sale

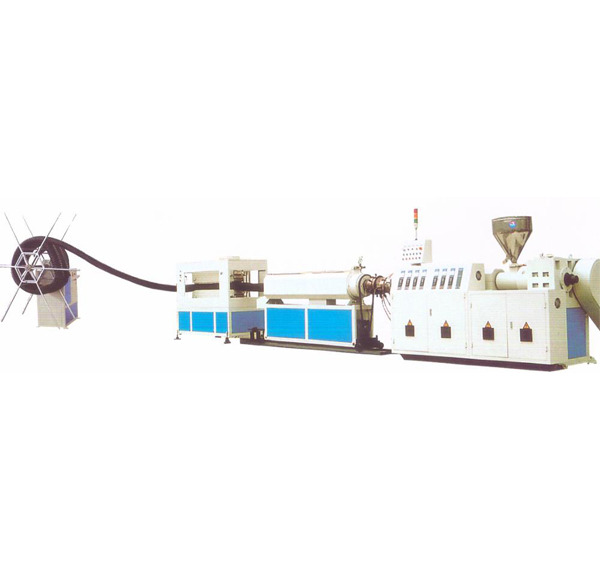

Plastic Pipe Production Line

UPVC roof tile production line belongs to the big profile machine in the PVC profile production. PVC profiles include PVC window profiles, PVC panels, PVC ceilings, PVC doors, PVC roofs, etc.

lHigh Pressure Helical Hose Sheath Production Line

lPVC Woven Fiber Reinforced Pipe Production Line

lGF-63 Twin Pipe Extrusion Production Line

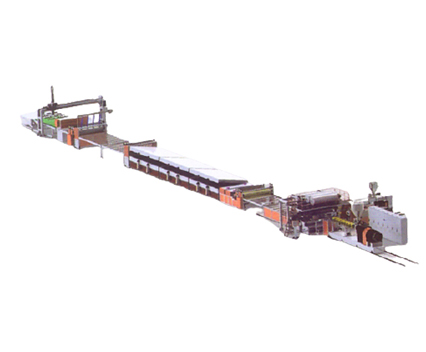

Plastic Sheet Extrusion Line

This machine developed by Kailite company is featured of unique structure, high degree of automatic, easy operation and stable reliable continuous manufacture performance.

lXPS Foamed Board Extrusion Line

lMelt Blown Fabric Production Line

lPE Foamed Sheet/Film Production Line

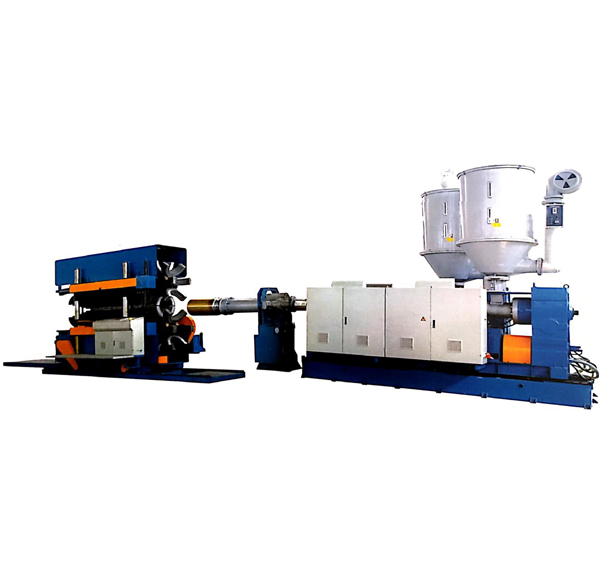

Plastic Profile Extrusion Line

Plastic profile production line is a professional production facility to produce PVC plastic profile, mainly producing doors and Windows series profiles, plates, sheets, micro-foaming profiles, etc.

lPlastic Extruding Profile Production Equipment

lPVC/PE/PP Wood-plastic Profiled Material Production Line

lMarble Decorative Rib Equipment

Wood Plastic Extrusion Line

My company in the original wood plastic equipment on the basis of improved research and development of wood plastic production lineequipment.

lPVC Wood-Plastics Composite Wallboard Production Line

lWPC Extrusion Production Equipment

What is Extrusion Line?

The plastic extrusion line is a mass production process in which the raw material plastic is melted and formed into a continuous contour. Extruded items include pipes, weather strips, window frames, plastic sheeting, tape and wire insulation. We are proud to have a complete plastic sheet extrusion production line, plastic pipe extrusion production line, plastic profile extrusion production line and wood plastic extrusion line. Our engineers and technicians use their expertise and development techniques to adapt to the latest plastic extruders in the rapidly changing market.

Processing of Plastic Extrusion Line

At the beginning, small plastic particles are put into the hopper placed on top of the barrel. The barrel is a heating hollow cylinder, a bit like a very thick tube. The screw type screw rotates inside the barrel. The rotation of the screw brings and pushes the plastic particles into the barrel. When the pill moves to the front end of the cylinder, the friction and electric heat of the cylinder will melt the plastic.

After the plastic melts, the rotating screw continues to act as a pump and forces the molten plastic through the mold. The mold is usually a piece of steel with the desired part shape. Once the melted plastic leaves the mold, it will be shaped like a finished product. Next, pull it through some kind of cooling device, usually using air or water for cooling. After cooling, the product can be rolled up, cut into sections, packaged or subjected to secondary operations.

Qingdao Kailite plastic machinery Co., LTD. is aprofessional plastic pipe production line manufacturers, we provide extrusion line machine, sheet extrusion lineand etc. Want to know more? Please contact us.

在线联系供应商

Other supplier products

| Plastic Sheet Extrusion Line | Plastic extruder adopts several extruders and is mainly applied to manufacture multi-layer plastic sheet of PP, HIPS, PE and other materials meetin... | |

| PET PP Waterstop Production line | Performance & Advantages Accurate dosing and raw material blending Preheat and dry circulating automatically Even plasticization, stable extrus... | |

| SJSZ Conical Twin Screw Extruder | Main technique parameter ( conical twin screw ) Model ltem SJSZ- 45*22 SJSZ- 50*22 SJSZ- 55*22 SJSZ- 60*22 SJSZ- 65*22 SJSZ- 80*22... | |

| PE/PVC Large Diameter Double Wall Corrugated Pipe Production Line | The Parameter of PE/PVC Large Diameter Double Wall Corrugated Pipe Production Line Model JG-SEG-630 JG-SEG-800 Raw material P... | |

| PE Spiral Reinforcing Carbon Pipe Production Line | The Parameter of PE Spiral Reinforcing Carbon Pipe Production Line Extruder SJ-90/30B SJ-65/30B Dile φ75-200 Φ50-150 ... |

Same products

| Iron Single Adjustable Cafe Rod Set | 卖方: Deqing Bochuang Hardware Co., Ltd | The Iron Single Adjustable Cafe Rod Setis a durable and stylish window treatment solution. Featur... | |

| Competitive Price OEM Waterproof Nylon Injection Molding Parts | 卖方: 河北二业橡塑制品有限公司 | Product Specification Description Products Name: Custom plastic and rubber parts Materials: Plast... | |

| Wholesale Plastic Injection Insert Molding Custom Plastic Parts | 卖方: 河北二业橡塑制品有限公司 | Product Specification Description Products Name: Custom plastic and rubber parts Materials: Pla... | |

| 塑料定制品 | 卖方: 河北二业橡塑制品有限公司 | Product Specification Description Products Name: Custom plastic and rubber parts Materials: Plast... | |

| z中国工厂定制塑料品 | 卖方: 河北二业橡塑制品有限公司 | Product Specification Description Products Name: Custom plastic and rubber parts Materials: Plast... |