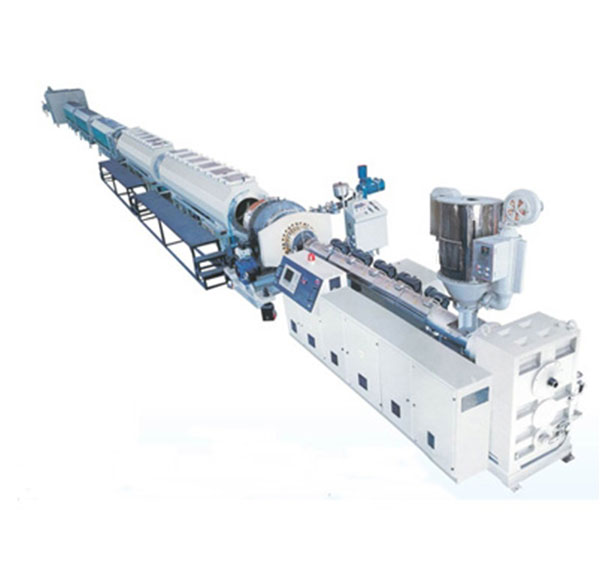

SJSZ Conical Twin Screw Extruder

- conical twin screw extruder chinaguarantees the quality of the matter.

- china extruder matching auxiliary machineis used to extrude different pipe, plate, profile and soft and rigid PVC granulation.

The Parameter of SJSZ Conical Twin Screw Extruders

Main technique parameter ( conical twin screw )

|

Model ltem |

SJSZ- 45*22 |

SJSZ- 50*22 |

SJSZ- 55*22 |

SJSZ- 60*22 |

SJSZ- 65*22 |

SJSZ- 80*22 |

SJSZ- 92*28 |

|

Screw diameter |

45/99 |

50/105 |

55/110 |

60/125 |

65/135 |

80/156 |

92/188 |

|

The screw rotates speed |

45 |

45 |

45 |

40 |

40 |

||

|

The biggest extruding capacity |

80 |

125 |

180 |

250 |

300 |

500 |

900 |

|

Main motor power |

22 |

30 |

30 |

37-55 |

55-75 |

132 |

|

|

Heat power |

15 |

18 |

20 |

20 |

28 |

35 |

85 |

Main technique parameter ( parallel twin screw )

|

Model ltem |

SJSZ-65/26 |

SJSZ-80/22 |

SJSZ-90/26 |

SJSZ-107/26 |

SJSZ-130/26 |

|

Screw diameter |

65 |

80 |

90 |

107 |

130 |

|

The screw rotates speed |

50 |

33 |

45 |

10-30 |

10-30 |

|

The biggest extruding capacity |

160 |

250 |

330 |

600 |

1000 |

|

Main motor power |

22 |

22-30 |

55 |

90-100 |

110-160 |

|

Heat power |

18 |

24 |

38 |

52 |

85 |

Features of Kailite Conical Twin Screw Extruder

- China twin screw extruderadopts side feeding technology, which improves the integrity of the material and greatly increases the output. The location and shape of the feeding inlet also have a great impact on the feed efficiency. Under the same parameters, the feed area increases, then the output increases. Under the same inlet area, the rectangular section has higher feeding efficiency than the circular section. The use of side twin screw feed is also based on this consideration.

Conical Twin Screw Extruder Working Principle

Difference Between Single Screw and Twin Screw Extruder

- twin screw extruder has excellent mixing capabilities because the intermeshing screws and a wide variety of professional screw designs allow precise adjustment of the degree of mixing to control the degree of mixing. On the other hand, the mixing capacity of a single screw extruder is very limited, and a special screw design is used to restrict the flow rate to enhance mixing.

- conical double screw pp extrudercan handle a high level of process flexibility and the ability to handle multiple processes, such as melting, mixing, cooking, venting, cooling, etc. However, in the case of a single-screw extruder, the output and screw speed are dependent, and the screw design with multiple tandem processing functions is limited.

- china double screw extrudercan provide higher process productivity.

- china conical dual screw mixerhas complex operation and higher process control requirements than single-screw extruders, simple operation and simple control process.

What is Twin Screw Extruder

The different from single screw extruder is that twin screw extruder has two parallel screws put into the barrel. They can drive by the two screws. Usually the extruder close bite and opposite rotary which extrude profile.

Twin Screw Extruder Process

Usually the extruder close bite and opposite rotary which extrude profile. The low speed is 10 r/min, the high speed rotary twin screws' is 300-600r/min, it's different from the teeth style extruder, is nearly to the single extruder principle.

Same direction teeth style conical twin screw mixer includes low speed and high speed. Opposite teeth style twin screws' gap is very small, so it can convey accurate.

Conical Twin Screw Extruder for Sale

Conical twin screw extruder design means conical shape of the twin screws, the work principle is similar. On the basis of the single screw, conical double screw extruder develops twin screw extruder, the low speed extruder has close teeth screw, one screw match the other close cooperation, conjugate screw shape.

Clean itself extruder, high speed extruder has close matched screw edge shape. It can design this screw into quite small screw gap. Make the screw qualify close self-clean function. It named closed same direction self-clean spiral twin screw extruder.

The Kailitemain products include plastic machinery series: extruder, plastic pipe production line, plastic sheet/sheet equipment, plastic pipe extrusion line, wood-plastic equipment, plastic recycling granulator, plastic crusher, etc.

在线联系供应商

Other supplier products

| HDPE Water And Gas Pipe Production Line | Features & Advantages: The Large Diameter HDPE/MDPE Pipe Extrusion Line research & developed by Jwell Machinery Co., features of unique str... | |

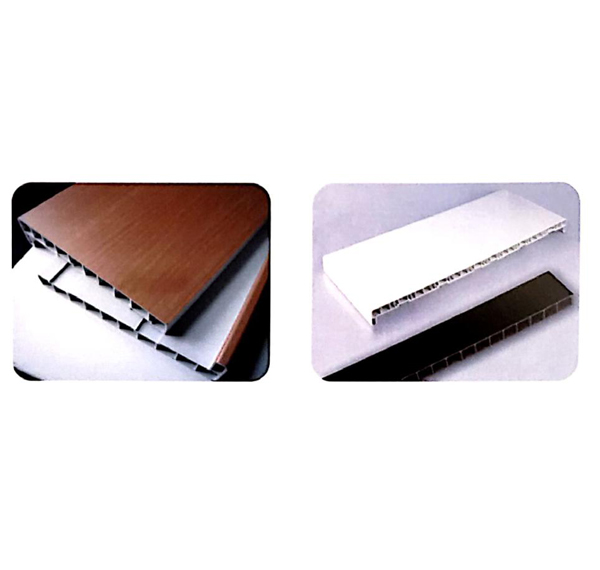

| PVC/PP/PE/PC/ABS Profile Extrsion Line | This line is the manufacture facilities of PVC plastic profile materials, including window and door series profile, plate, sheet tiny bubble profil... | |

| PE Physical Foamed Net Machine | PE foamed net is a new soft packing material. Due to ist unique expanding reticulation structure and the elastic foamed net film. Performance &a... | |

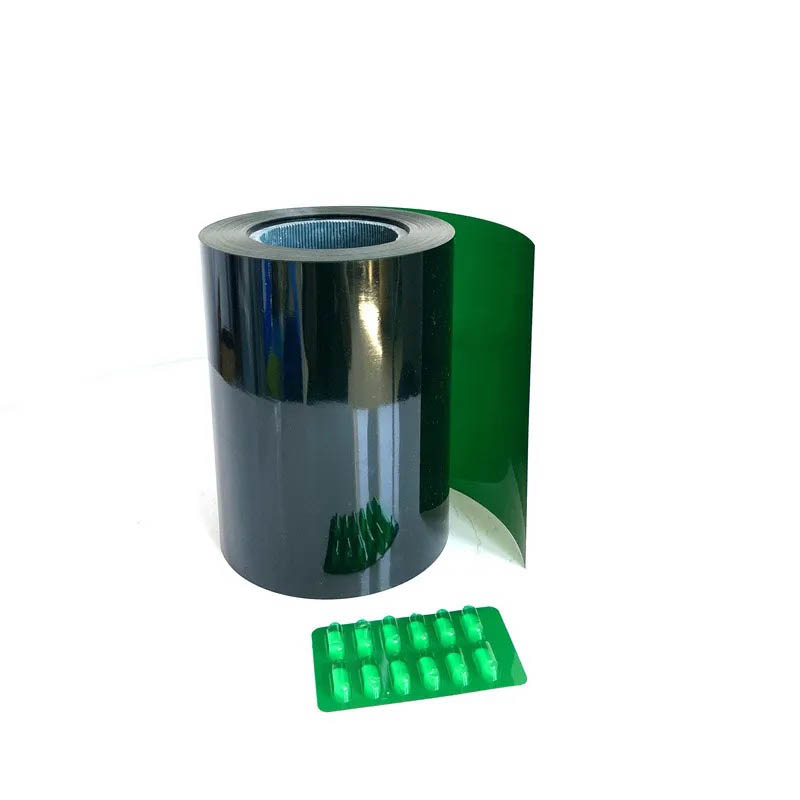

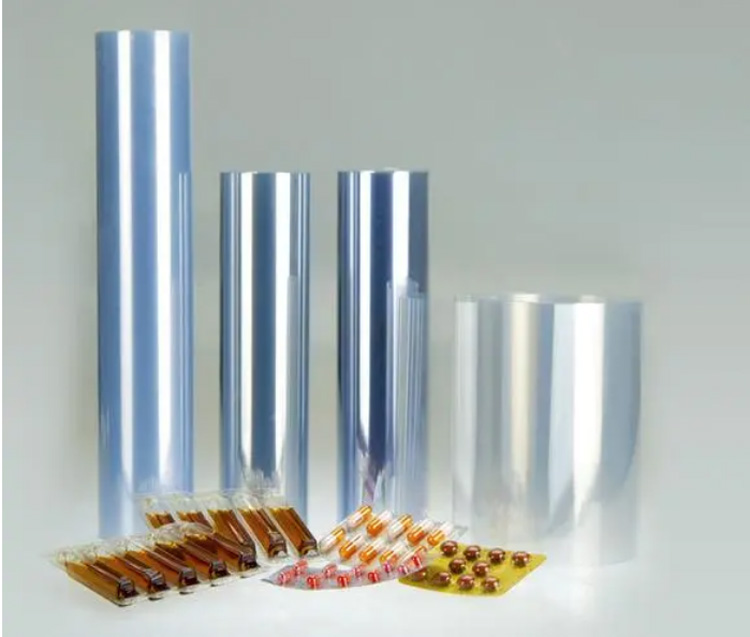

| Plastic Sheet Extrusion Line | Plastic extruder adopts several extruders and is mainly applied to manufacture multi-layer plastic sheet of PP, HIPS, PE and other materials meetin... | |

| PP-R/PP/PE Plastic Tube Production Line | That production line design special, adoption BM separate type efficiently the pole of automating the degree is high, operation convenience, contin... |