High quality high tensile galvanized rail fish bolt

Fishtail Bolts (Fish Bolts) are mostly used in rail joints (Railway Fishplates) for fixing purposes. Sometimes, hexagon bolts can be used instead. Fishtail Bolts (4).png Fishtail bolts are mainly used in track laying in the metallurgical industry, coking industry, and steel industry, where the rail and rail joints are fastened. Fishtail Bolts (2).png Fishtail bolt is a mechanical part, a cylindrical threaded fastener with a nut. Bolt: A fastener consisting of a head and a screw (cylinder with external thread). It needs to be matched with a nut to connect the two parts with the through hole. Bolt connection is this type of bolt connection. If the nut is unscrewed from the bolt, the two parts can be separated, so the bolt connection is a detachable connection. Fishtail Bolts (3).png Type and material of fishtail bolt Models are Φ14×70, Φ16×75, Φ18×90, Φ20×90, Φ22×135, Φ24×135, Φ24×145, Φ24×170, etc. They are usually formed by hot pressing with a friction press, with a buckle length of 50mm, and cold The upsetting is mostly used in the connection of rail joints. Fishtail bolts are made of: Q235 and 45# steel and insulated fishtail bolts. Fishtail Bolts (1).jpg Railway Fish bolt Grade 4.6 5.6 8.8 10.9 Material Q235 35# 45# 40Cr Mechanical properties Tensile strength: ≥400Mpa Tensile strength: ≥500Mpa Tensile strength:≥800Mpa Tensile strength: ≥1000Mpa Yield strength:≥240Mpa Yield strength:≥300Mpa Yield strength:≥640Mpa Yield strength:≥900Mpa Elongation:≥22% Elongation:≥20% Elongation:≥12% Elongation:≥9% Cold bending: 90 degree without crac Cold bending: 90 degree without crac Cold bending: 90 degree without crac Cold bending: 90 degree without crac Surface plain (oiled), Oxide black, Zinc, HDG, wax, bitumen, Dacromet, Sherardizing Standard refers UIC864-2 Fishtail Bolts (2).jpg What should be paid attention to when installing fishtail bolts on railway fishplates? 1. The contact part and bolts of fish plate and rail should be oiled. 2. When wearing fishtail bolts, the nuts must be staggered inside and outside. 3. The procedure for bolting, such as using a four-hole fishplate, first tighten the middle two, then tighten the two sides, and then tighten the middle two again. 4. When screwing the fishtail bolts, one person should use a 55 cm screw wrench as the standard, and not too long a screw wrench or two persons. 5. When the fishtail bolt cannot be put on, use a hammer to hit both ends of the fishtail plate, align the eyes, and do not use a hammer to drive the fishtail bolt in. Fishtail Bolts (5).jpg Fishtail Bolts (8).jpgFishtail Bolts (6).jpgFishtail Bolts (7).jpg Fishtail Bolts (3).jpg Fishtail bolt grade meaning According to relevant standards, the performance grades of fishtail bolts are divided into more than 10 grades, such as 3.6, 4.6, 4.8, 5.6, 6.8, 8.8, 9.8, 10.9, and 12.9. The bolts of grade 8.8 and above are made of low carbon alloy steel or medium carbon steel. After heat treatment (quenching and tempering), they are generally called high-strength bolts, and the rest are generally called ordinary bolts. The bolt performance grade label consists of two numbers, which represent the nominal tensile strength value and yield ratio of the bolt material. Fishtail Bolts (1).png Production Processs Fishtail bolt inspection: Bolt inspection is divided into manual and machine. Manual is the most primitive and most commonly used consistent detection method. In order to minimize the outflow of defective products, the general production company personnel inspect the packaged or shipped products by visual inspection to eliminate defective products (defects include tooth injuries, mixing, rust, etc.). The other method is automatic machine inspection, mainly magnetic particle inspection. Magnetic particle inspection uses the interaction between the leakage magnetic field at the bolt defect and the magnetic powder to deal with the difference between the magnetic permeability of the bolts (such as cracks, slag inclusions, mixing, etc.) and the magnetic permeability of steel. These materials are discontinuous after magnetization. The magnetic field will be turbulent, forming part of the magnetic flux leakage, and the leakage magnetic field will be generated on the surface of the workpiece, thereby attracting the accumulation of magnetic powder at the defect where the magnetic powder is formed-the magnetic mark. Under proper lighting conditions, the defect position and shape will appear. The accumulation of these magnetic powders is observed and explained, and the purpose of rejecting defective products has been achieved. testing for rail clip Our Services Maanshan Ruika Metal Products Technology Co., Ltd. established by experienced crew on the rail&track field, is a professional & reliable supplier that provides all kinds of rail & track accessories. As an international trade subsidiary of Maanshan Ruika Metal Products Technology Co., Ltd. as founded in 1997. We have more than two decades experience on this field, With advanced technology ,powerful processing capacity and excellent service, our products have been well recognized by our customers from domestic & overseas market. Our PeopleFactory Visiting Packaging & Shipping Packing FAQ Q: Are you trading company or manufacturer ? A: We are a factory. Q: How long is your delivery time? A: Generally within 25-30 days for a 20ft container after the prepayment received. Q: What is your terms of payment ? A: 30% of the payment in advance , the balance before shippment via T/T. Q: Will that be possible for us to receive pieces of samples for approval? A: Sure. The samples can be supplied for free but the freight counts on you. Q: What's the packing way? A: Bundled in steel strips with iron/wood pallets. Q: How long will it be the quotation valid? A: The validity is 15 days in general, but also depends on the quantity and special conditions. It will be shown in every quotation. Q: What is MOQ? A: 20’’ container in general, depending on whether enough stocks available for small quantity; customized products accepted. Q: Do you have any certifications regarding Fishtail Bolts? A: We have passed the certification of CRCC in China and ISO9001:2008 overseas. Before shipment, Certificate of Quality can be supplied. We also accept Third Party Inspection from clients, with free samples to supply. Contact us If you have any questions, pls feel free to contact us as below: Email:

Other supplier products

|

|

Rail Tie Plates for concert sleeper |

A tie plate is also called a baseplate or sole plate. Ruika specializes in producing rail fastening and tie plate is one of our main products. Ra... |

|

|

Square Head Lag Track Bolt |

Track bolts, also called fang bolts or rail anchor bolts, are used to fix steel rails and rail chairs torail tie plates, or to fastenrail jointst... |

|

|

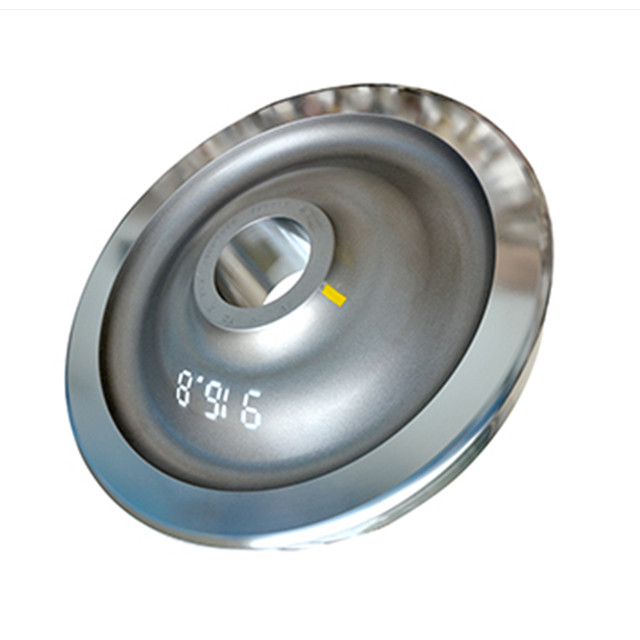

Railway Wheels Forged Casting Steel Train Wheel Rail Wheel |

Widely used in logistics, freight wagon, muck car, and other railway transport. It can be designed and manufactured according to user’s req... |

|

|

Rail fishplate splice bar used for railroad fastening |

Rail joints, also named splice bar, fishplates or rail joint bar, is a metal bar that is welded into two rails in order to join them together. It... |

|

|

Fastening railway supplies rail clamps crane rail clip from China |

Ruika metal is one stop service for design, production, logistic delivery for metal products. Professional and experienced technical and marketing ... |

供应产品

Same products