Brass and Copper Precision Machining

Is Brass Easier to Machine than Copper?

Copper is a soft, malleable metal that is an excellent conductor of electricity and heat, which makes it suitable for use in a wide range of industries, including electronics, aerospace, and automotive.

Brass cnc machining parts is an alloy of copper and zinc, and it is often used in Swiss machining because it is relatively easy to machine and has good corrosion resistance. Brass is generally easier to machine than copper in Swiss machining due to its lower hardness and better machinability characteristics.

In Swiss machining, both brass cnc and copper can be turned, drilled, and milled to create complex shapes and features with high precision. The choice of material will depend on the specific requirements of the part being produced, as well as factors such as cost, availability, and compatibility with other components.

Benefits of Precision Swiss Machined Brass and Copper Parts

Brass and copper cnc machining in Swiss machining offers several benefits due to the unique properties of these materials and the capabilities of the Swiss machining process. Here are some advantages of brass and copper machining in Swiss machining:

Excellent Machinability: brass machining and copper are known for their excellent machinability, making them ideal for Swiss turn machining. They are softer than many other metals and can be easily shaped, formed, and machined to complex geometries with tight tolerances.

Superior Conductivity: Both brass and copper are highly conductive materials, making them suitable for electrical and thermal applications. In Swiss machining, brass and copper can be precisely machined to create connectors, terminals, electrical contacts, and heat sinks that require excellent electrical and thermal conductivity.

Corrosion Resistance: Brass and copper form protective oxide layers on their surfaces, protecting them from environmental factors and enhancing their durability. Swiss machining can produce components with precise dimensions and smooth surfaces, further improving their resistance to corrosion.

Strength and Durability: Brass and copper are inherently strong and durable materials, making them suitable for various applications. Swiss machining allows for the production of precise and robust components that can withstand high loads, vibrations, and mechanical stresses.

Aesthetic Appeal: Brass and copper have visually appealing appearances. Their warm, attractive colors and ability to be polished, plated, or finished make them desirable for applications that require an aesthetic touch, such as decorative or architectural components.

By leveraging the benefits of brass and copper machining in Swiss machining, Falcon can produce high-quality, precision components that meet stringent requirements in various industries, including automotive, electronics, aerospace, medical, and more.

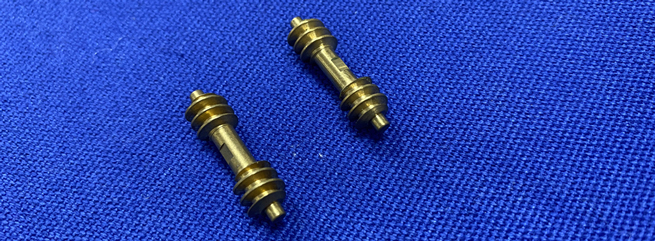

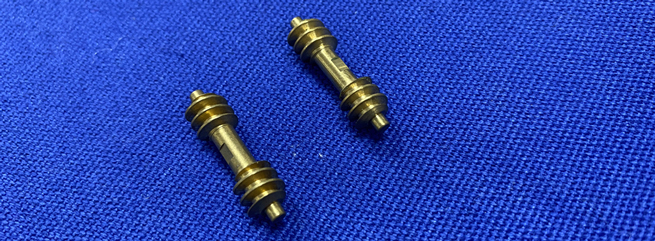

Brass and Copper Machining part

Falcon Brass and Copper Machined Parts Application

Brass and copper are commonly used materials in Swiss machining due to their excellent machinability and desirable properties. It finds applications in a wide range of industries. Here are some common areas where these parts are used:

Automotive Industry: Brass and copper machined parts are used in various automotive applications, including fuel systems, engine components, electrical connectors, cooling systems, and braking systems.

Electronics and Electrical Industry: Brass and copper machined parts are widely utilized in the electronics and electrical sectors. They are used in connectors, terminals, switches, circuit boards, heat sinks, and electrical contacts. The high electrical and thermal conductivity of brass and copper makes them ideal for efficient and reliable electrical connections.

Medical Industry: Brass and copper are used in surgical instruments, implants, medical connectors, diagnostic equipment, and various components requiring antimicrobial properties. Copper, in particular, exhibits natural antimicrobial properties, making it suitable for healthcare applications.

Industrial Equipment: Brass and copper machined parts are utilized in various industrial machinery and equipment. They can be found in pumps, valves, gears, bearings, connectors, and other components that require high strength, wear resistance, and reliability.

Typical Machined Brass and Copper Parts

Pipe fittings

Connectors

Gears

Shafts

Valves

Bearings

Aluminum 5086

Terminals

And more custom brass and Cooper components

Common Used Grades of Brass and Copper

The choice of brass and copper grade depends on the specific properties required for the application at hand, such as electrical conductivity, corrosion resistance, machinability, and mechanical strength.

Here are some commonly used grades of Swiss turned brass and copper parts.

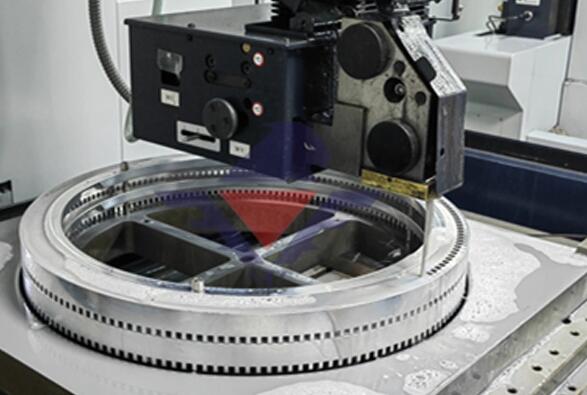

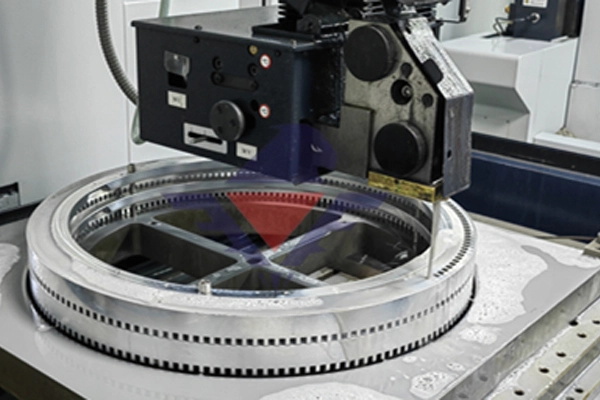

Falcon Brass & Copper Machining Services

Falcon is a leading provider of precision Swiss machining solutions, serving customers worldwide for over 20 years. We are experienced in manufacturing complex parts at tight tolerances for customers in the medical, automotive, and electronics industries. Our commitment to quality is evident through our ISO 9001:2015, ISO 13485, and IATF 16949 certifications.

We are dedicated to continuous improvement, ensuring that we stay at the forefront of the industry and provide top-notch brass and copper machining services. If you're looking for a reliable partner for your next Swiss machining project, contact us or request a quote today.

For more information about precision machining, please feel free to contact us!

Other supplier products

|

|

Brass and Copper Precision Machining Services |

Brass and Copper MachiningServices

Is Brass Easier to Machine than Copper?

Copper is a soft, malleable metal that is an excellent conductor of ... |

|

|

Brass and Copper Precision Machining |

Is Brass Easier to Machine than Copper? Copper is a soft, malleable metal that is an excellent conductor of electricity and heat, which makes it s... |

|

|

Micro Machining |

Micro machining is a type of manufacturing technique used to produce small and precise parts, components, and structures. This manufacturing proces... |

|

|

Precision Titanium Machining |

Precision Titanium Machining

Why is Titanium So Hard to Machine?

Titanium, as a challenging material, has a unique combination of properties in... |

|

|

Custom Micro Machining Service |

Micro machiningis a type of manufacturing technique used to produce small and precise parts, components, and structures. This manufacturing process... |

All supplier products

Same products