Overmolding & 2k Molding

The same type of material of different colors is usually used for two-color injection overmolding(or 2k injection molding)so that the bonding strength of the first color and the second color plastic is the best, but due to the functional requirements of the product, the performance difference of the two materials actually used may be very big, if the elastomer is injected into the surface of a rigid material, the most difficult thing to solve during 2k moulding process is the delamination and shedding of the bonding surface of the two materials.

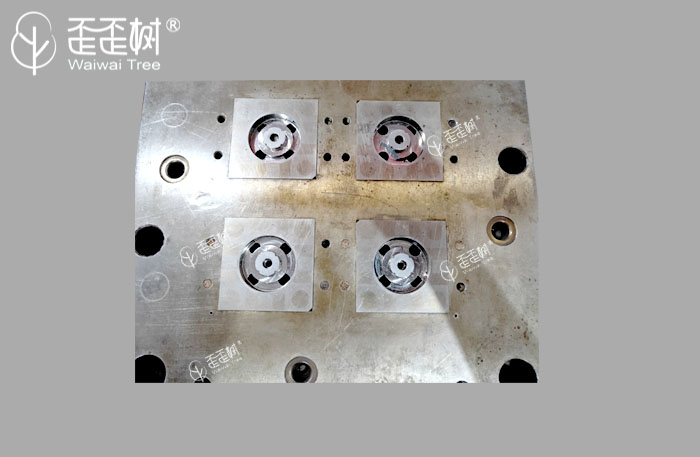

OVER-MOULDED 2K MOLDS FOR SALE

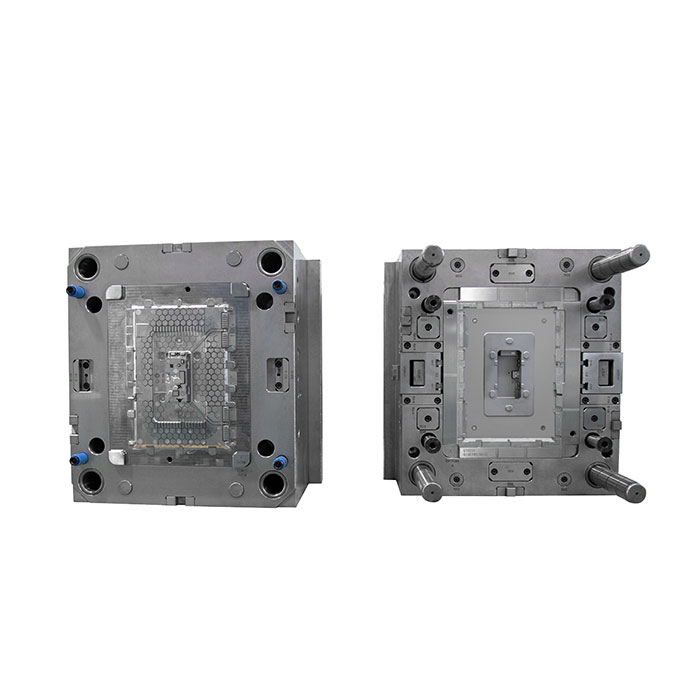

Water Proof Plastic Enclosure Mold

The product will be made by two times, which will inject the second piece after finishing the first piece in the other mold and different injection machine, normally will be no specific request for 2 different pieces injection time, injection machine.

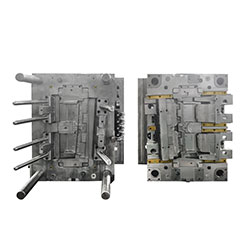

Drip Tip Mold

The two-color molding will be made in one same injection machine at the same time by 2 times injection, with 2 injection barrels and 2 different injection gates by 2 different molds, but the product will be picked up one time, it will request 2 molds in one specific 2k injection machine to finish final injection.

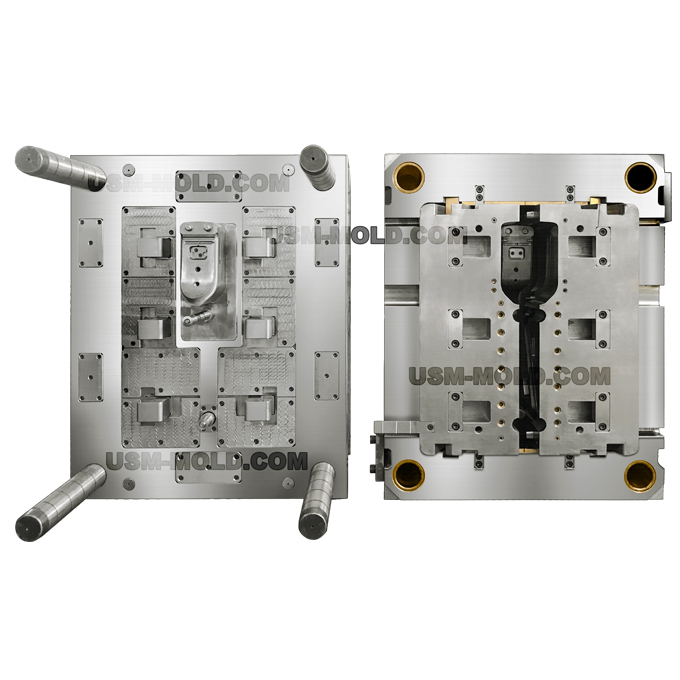

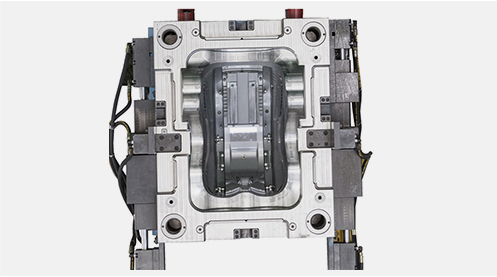

2K Mold

This mold will be put with a movable core on gate position of the core side, the movable core is pushed to the rising position when injecting the first-color material, and the first color part is solidified, After that, the movable core return back through the action of the hydraulic device, at this time, another barrel injects the second color material into the space left by the retreat of the core, the mold is opened and the part is taken out after finishing one injection after it's solid.

Material Selection For 2K Plastic Injection Moulding

In addition to meeting the requirements of product function and appearance in the material selection of two-color products, whether the adhesion between raw materials can be solved well will be related to the success of two-color products in 2k moulding process is also the difficulty of 2k moulding technology.

The following four points should also be considered in the selection of materials for two-color injection molded products:

- plastic injection overmoldingprocess, because in the 2k injection molding process, although the two injection cycles are relatively independent, the entire injection cycle time is the same, so it is necessary to focus on controlling the injection time of the two-cavity injection cycles, cooling time and pressure holding time, so as to ensure that the product can be produced normally; at the same time, it is also necessary to control the injection volume, injection speed, and mold temperature, this is because in 2k plastic injection moulding, changing the injection volume and mold temperature can make the degree of mixing of the plastic part or the thickness of each layer occur. Change, and whether the injection speed is appropriate or not, will directly affect whether the melt may have turbulent flow or cause the outer layer of the plastic part to rupture during the flow process.

2K Molding Design Guide

Structural design is the most important part of 2k moldingproduct design, the structure design of the product should not only consider the function of the product but also consider whether it meets the processing conditions and the complexity of the processing mold, in the design of two-color injection products, in addition to the issues to be considered for ordinary injection products, the following aspects should also be considered:

As professional 2k molding factory, we will do our best to provide more types of related products for sale, if you have needs, please contact us.

As one of injection molding manufacturers, we will do our best to meet all the needs of customers.

Send product request

Other supplier products

| Voice Operated Switch Mold | Switch Plate Mold The function of the smart home system is extensible, so it can meet the demands of different users. For example, the user's smar... | |

| Automotive Mold | Large drop of automotive moldtop and bottom; The mold manufacturing technology is complicated; The injection system is many and complicated; The mo... | |

| Medical Plastic Injection Mold | For medical plastic components manufacturer, it means that medical supervisors are required to supervise and manage the materials used to manufactu... | |

| Bike Frame Mold for Kids | Bike Frame Mold Nowadays, gas-assisted injection molding has been successfully applied to the fields of the automotive, home appliance, furniture,... | |

| Medical Plastic Injection Mold | Medical Plastic Injection Mold For medical device injection molding companies, it means that medical supervisors are required to supervise and man... |

Same products

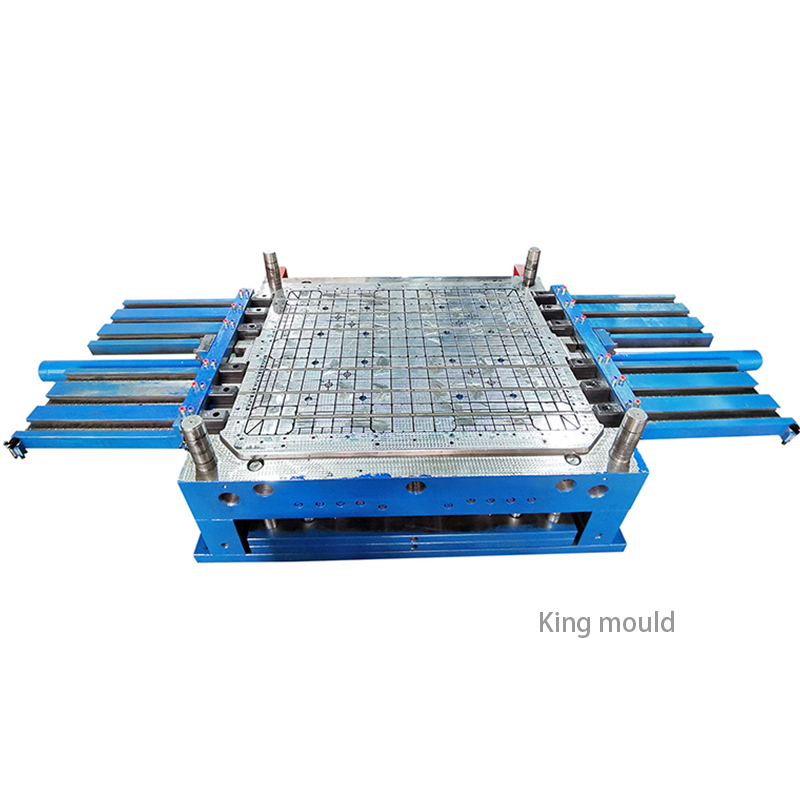

| Plastic Injection Lightweight Pallet Mould | Seller: Zhejiang Huaqi Information Technology Co., LTD | Discover the Pallet Mould, a game-changer in the world of logistics and material handling. Our Pa... | |

| Flange Molding | Seller: ZHEJIANG AOBANG TECHNOLOGY CO.,LTD | Flange Molding Flanged joint is the main connection method in pipeline construction. Compared to... | |

| Injection Mold Manufacturing | Seller: HANKING MOULD ENGINEERING LTD. | HanKing Mouldhas the advantages of low labor cost, short mold manufacturing lead time, excellent ... | |

| Car Seat Mould for Kids | Seller: Green Vitality Industry Co., Limited | Child safety seats are seats specially designed to protect children from injury or death in a col... | |

| Industrial Plastic Injection Mold | Seller: Green Vitality Industry Co., Limited | The injection molding part is replacing metal products in many fields of industrial applications ... |