DRUM CAP SEAL

Tamper-evidence barrel cap seal are used for industrial container opening and widely applied in filling line on either steel drums or plastic drums. Chongyi is one of the top drum cap seal suppliersand drum cap seal suppliers in China. The 55 gallon drum bung seals, cooperating together with and differentiating from drum closure, are relatively lightweight and disposable, which makes them an ideal option as an anti-theft and directness-prevent cover. The drum lock sealhas full range of colors and customized logo designs which are frequently requested as an anti-counterfeiting selection. Drum makers and drum users can always find suitable drum cap seal for their filers from us, a professional drum cap seal company!

Drum Cap Seal Types

As one of the leading drum cap seal manufacturer, XEAL offers different types of 55 gallon drum cap seals, including metal cap seal and plastic drum cap seal, each suited to specific industrial applications. The following is a detailed introduction to our 55 gallon drum cap seals.

Metal Drum Cap Seal Plastic drum cap seals

White Drum Cap Seal

Printed Drum Cap Seal

METAL DRUM CAP SEAL

Metal Drum Cap Seal

Made of tinplate material and with flow-in gasket, XEAL® metal tab seal is with G2 and G3/4 standard size for steel drum opening mouth. Metal drum capseals should be installed by compatible drum cap sealcrimping tool, and tear up with drum cap seal remove tool.

Read More About Metal Drum Cap Seal

Why Choose Chongyi Drum Cap Seal

Drum cap seal, as well as drum closures, are one of the most essential and important sealing parts for industrial container packaging. The drum cap seal offers leakage, theft, counterfeiting and dirt-prevent to tight head drums. Chongyi, one of the most experienced drum cap seal manufacturers, has strong production capacity and excellent delivery services, which can always deliver the best value of barrel cap seal to customers.

How to choose the right drum cap seal

Choosing the right drum cap seal is essential to ensure the safe transportation and storage of hazardous materials. The first step is to determine the type of drum closure required for the specific application. Drum cap seal suppliers offer a range of options, including metal and plastic drum cap seals, and different sizes suitable for different drum types, such as 55 gallon drum cap seals. The sealing tool must also be chosen based on the type of drum cap seal, such as a crimping tool for metal cap seals or a snap-on tool for plastic drum cap seals. The material used for the drum cap seal should be based on the type of contents of the drum, as some materials may react with certain chemicals. Finally, it is essential to ensure that the selected drum cap seal is compliant with relevant regulations. With the right selection of drum cap seal and drum cap sealing tool, companies can ensure the protection of workers and the environment from hazardous materials.

Best practices for installing drum cap seal to prevent loosening or tampering

Ensuring the proper installation of a drum cap seal is critical to prevent any tampering or loosening of the container. Drum cap seal suppliers offer a range of options, including metal and plastic drum cap seals suitable for specific drum types, such as 55 gallon drum cap seals. To ensure a secure seal, it is important to use the appropriate drum cap sealing tool, like a crimping tool for the metal drum cap seal or a snap-on tool for the plastic drum cap seal. Best practices for installation include cleaning the drum closure and cap seal of any debris. Crimp-on metal cap seals require a specialized crimping tool to apply the necessary pressure to ensure a secure seal, while snap-on plastic cap seals need to be pressed down firmly to ensure proper snapping onto the drum. To detect any unlawful access or tampering, companies can mark or number the drum cap seal and conduct regular drum closure inspections. Proper installation and maintenance of the drum cap seal will help maintain seal integrity and prevent any leakage or hazardous spillage. With these best practices, companies can achieve regulatory compliance and ensure the safety of workers and the environment.

Drum Cap Seal FAQ

How do you seal metal drums?

How do you seal plastic drums?

Which is the cost-effective way for selecting a drum cap seal?

There are both disposable and reusable drum cap seal available in Chongyi, one of the top drum cap seal manufacturers in China. The transparent plastic cap seal is the most cost effective way to protect the opening free from water and dust, and can be reused for long time.

Which is the best secure option for my steel drums?

We recommend the 2'' and 3/4'' steel cap seal with customer's logo design on it, mostly we offer embossing logo on the 55 gallon drum cap seals which is more anti-counterfeiting, further QR code or DM code which traceble functions. Chongyi is one of the best drum cap seal.

For more information about drum bung fittings, please feel free to contact us!

Send product request

Other supplier products

| Lacquered Drum Plug | Lacquered barrel bung plugsis G2 and G3/4 steel drum plugswith lacquered resins for better resistance to the drum filers, such as food contact, sol... | |

| Pail Crimper | pneumatic pail crimperis the sealing tool used to seal lids of metal open head containers, including lubricant bucket, chemical bucket, and paint b... | |

| Buttress Plastic Bung | Buttress bungis with coarse thread, as well as 2'' NPT plastic bung with fine thread, designing for induatrial plastic drums, HDPE barrels, plastic... | |

| Zinc Plated Drum Plug | Zinc plated drum plug is G2 and G3/4 round shape bungs which screw into drum flange, those are equipped with gasket of BUNA, EPDM, PE, Viton or irr... | |

| Drum Paint Cap | Drum paint cap is a type of cap used during production of steel drum. Its main function is to prevent paint entering drum inside during drum painti... |

Same products

| Seamless pipe | Seller: Eastern Steel Manufacturing Co.,Ltd | Seamless pipe is a long steel strip with a hollow cross-section and no seams around it. &zw... | |

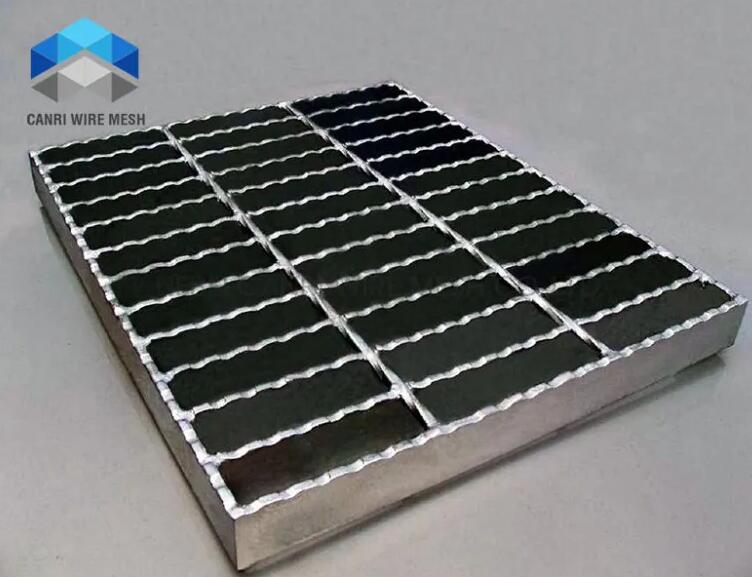

| Galvanized Steel Grating for Drainage | Seller: Hebei Canri wire Mesh co.,Ltd | Galvanized Steel Grating for Drainage Steel gratingfor drainage, also known as galvanised draina... | |

| Floor Grating | Seller: Hebei Canri wire Mesh co.,Ltd | Floor Grating Floor grating, also known as open grid flooringor bar grating, is a type of structu... | |

| Serrated Bar Steel Grating | Seller: Hebei Canri wire Mesh co.,Ltd | Serrated Bar Steel Grating Steel bar gratinghas two surface type: serrated surface and smooth su... | |

| Stainless Steel Grating | Seller: Hebei Canri wire Mesh co.,Ltd | Stainless Steel Grating Stainless steel gratinghas been the standard industrial foot walk produc... |