gypsum powder machine

gypsum powder machine

annual capcity : 20000T to 200000T

Broken parts: 300 days times 16 hours

Grinding parts: 300 days x 24 hours

Burning parts: 300 days x 24 hours

Store conveying parts: 300 days x 24 hours

Three-phase AC380V, 50 hz;

Single-phase AC220V, 50 hz.

No waste water discharge waste residue, emissions accord with state environmental protection emissions standards.

Coal, the chain grate stoker (gas, light oil, heavy oil).

Suitable for construction building materials industry (paper face plasterboard, gesso block, paint the plaster, cement additive, etc.).

Brief production

The crusher breaks the big sized gypsum ore into small ones with 25mm in diameter. After storing and conveying,they are taken into the mill for grinding. Then, the powder concentrator carries the gypsum powders which match to the needed fineness to calciner for calcining. Others are back to the mill until it is qualified. In the end, after calcining, the qualified gypsum powder are sent to clinker container for storing, or are sent to the manufacturing workshops for use.

|

Equipment list for 60,000 tons Gypsum powder production line |

||||

|

Crusher system |

Crusher |

800x1200 |

30kw |

|

|

Elevator |

TH315 |

|||

|

Raw material container |

60m3 |

1 set |

||

|

Mill system |

The body of raymond mill |

4R3216 |

2 sets |

|

|

Driver motor |

Y225S-4 |

37kw x 2 |

||

|

Air blower motor |

Y220M-4 |

30kw x 2 |

||

|

Calcining system |

The body of calciner |

1 set |

||

|

Roots blower |

1 set |

|||

|

High voltage electrostactic |

1 set |

|||

The content of soluble without water gesso: < 5%.

Six, origin requirements (not including raw materials and finished products of warehouse)

Equipment need workshop specifications:

30 meters in length, width is 15 m.

Send product request

Other supplier products

| Calcium silicate board processing machine | About us : We are china famous brand of manufacturering building material equipment line , has gain manyhonors , recived good reputation form ... | |

| fiber cement board production line | Product Information Product Name Raw Materials Cellulose Fiber, Quartz Sand, Portland CementStandard Size 1220X2440MM / 1200X2400MMMaxium Widt... | |

| gypsum powder plant | gypsum powder plant Annual capcity 20000T to 200000T per year The production line outline: This design is an annual output of 30000 tons of cons... | |

| Calcium silicate board equipment | Production Capacity: 2 million to 8 million square meter Calcium silicate board per year Products Specifications: Calcium silicate board p... | |

| Calcium silicate board plant | Calcium silicate board plant technoloty: calcium silicate board use inorganic mineral fiber or cellulosic fiber as reinforcement agent and silice... |

Same products

| AEMK 588 Loader | Seller: AEMK MACHINE CO.,LTD | Cab Height :2670mm Overall Dimensions ( L * W * H ):5700*2000*2670mm Front Wheel Counterweight ... | |

| Quick Change Worktable | Seller: Nextas Co.,Ltd | Quick Change Worktable Zero Point Pneumatic Chuck Zero Point Positioning Datum System NE... | |

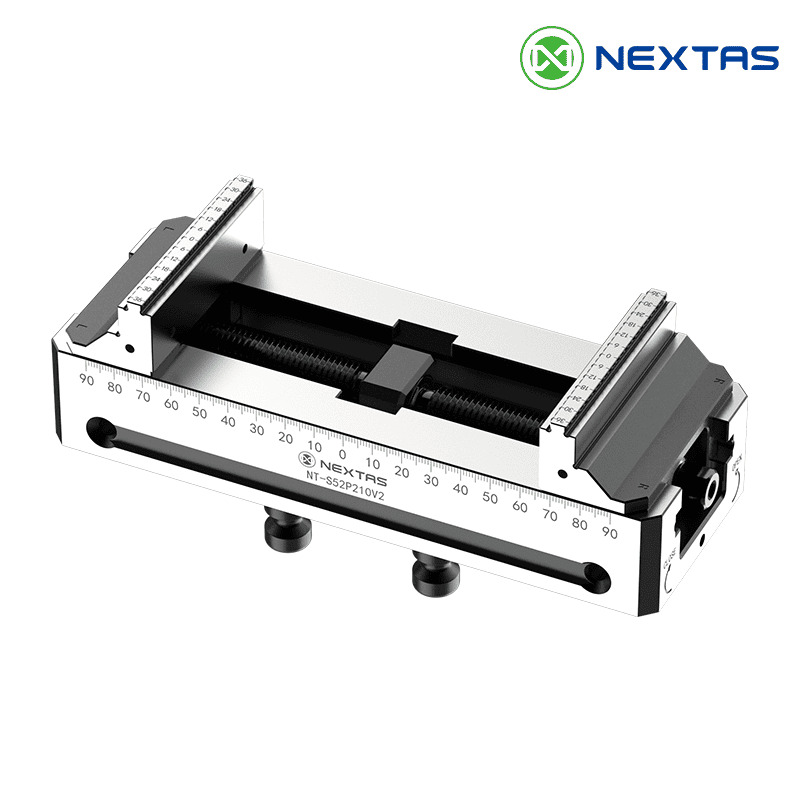

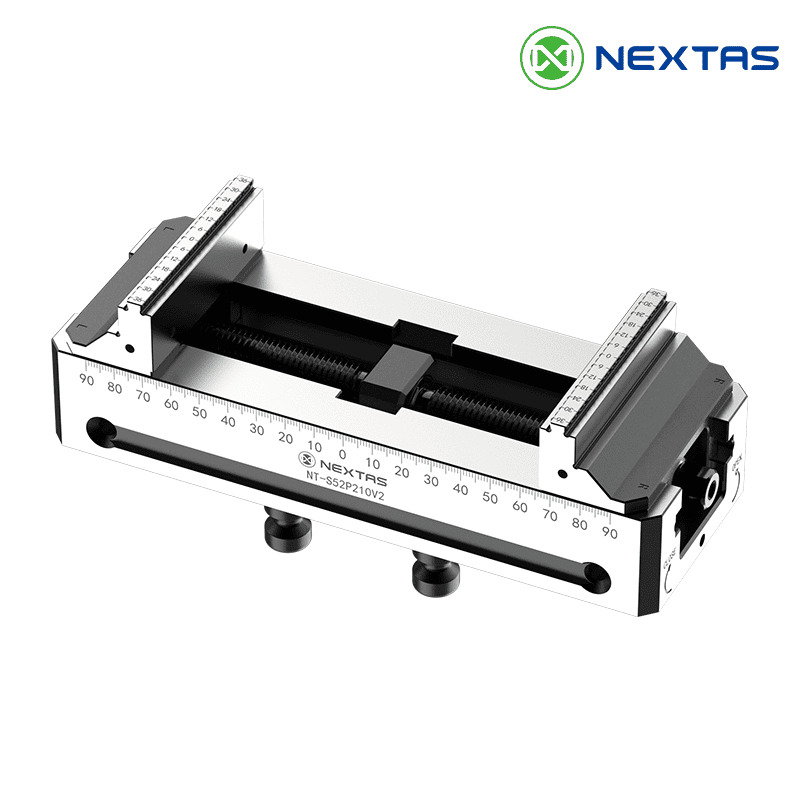

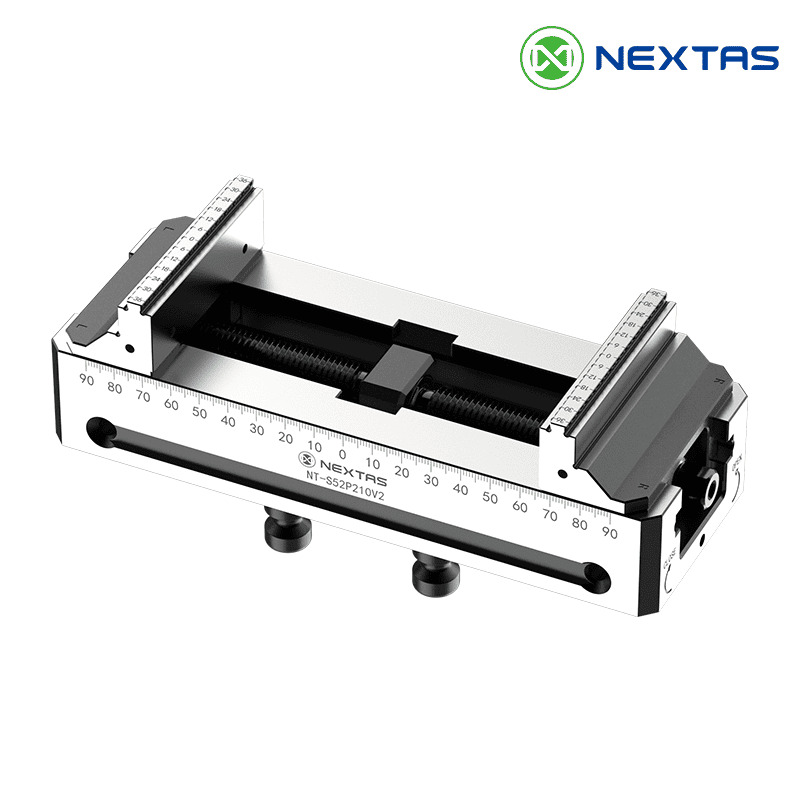

| Self Centering Vise | Seller: Nextas Co.,Ltd | Self Centering Vise Key Advantages High precision: repeatability as tight as ≤ 0.005 mm ... | |

| BDS Positioning Chuck | Seller: Nextas Co.,Ltd | BDS Positioning Chuck Self Centering Vise Self-centering vise is a type of workholding tool that... | |

| Quick Change Pallet System | Seller: Nextas Co.,Ltd | Quick Change Pallet System Quick Change Pallet System Quick Change Pallet System delivers m... |