Sludge Dryer Machine

CIC's sludge drying machine process was originally developed for the development of high viscosity media in the concentrating chemical industry and has long been used for the heavy equipment machinery separation of liquid/liquid and liquid/solid media that are difficult to separate. After continuous improvement, this sludge treatment and disposal technology has become a mature technology in the field of rotary sludge dryer machine. If you know something about our sludge dryer machine, you should know that we have a complete set of solid waste incineration systems. Although our incineration system can handle high water content sludge, if the sludge accounts for a large proportion, the large amount of water contained in it will have a huge impact on the stable operation of the entire incineration system. In addition, the use of a large amount of auxiliary fuel due to the evaporation of this moisture causes an increase in processing cost. If the main material processed by your incineration system is sludge, we can also provide a whole set of sludge drying equipment as a pretreatment sludge dryer system for sludge treatment and disposal.

CIC Achievement in Sewage Sludge Dryer Machine

CIC has successfully applied this technology to multiple sludge dewatering centrifuge with great success.

CIC sludge drying machine equipment be used in the wastewater treatment plant of Geweite Environmental Protection New Energy Co., Ltd.

Principle of Rotary Sludge Dryer Machine

In CIC heavy equipment companies, The working principle of the sludge drying machine is to transfer the material (wait to dry) into the sealed chamber from the inlet and use the saturated steam as the heat source to heat the material indirectly. Through the hollow shaft components (disc, feather root, mud scraping stick), it can fully stir and push the material to make the water evaporate faster, so as to achieve the purpose of drying the material by sludge treatment and disposal.

The treated materials for sludge drying machine equipment include industrial sludge, domestic sludge, mixed sludge, etc.

Technical Parameter of Sludge Dryer Equipment

|

Capacity |

70-100 t/d |

|

Moisture content before process |

80% |

|

Moisture content after process |

40% |

|

Main motor power |

90 kw |

|

Reduction ratio |

1:55 |

|

Rotate speed of hollow shaft |

0~10 rpm |

|

Diameter of hollow shaft |

φ 750 |

|

Diameter of disc |

φ 2100 |

|

Heat transfer area |

~41 m2 |

|

Heat source |

saturated vapor |

|

Working pressure |

|

|

Working temperature |

<170℃ |

|

Size of machine |

~11700×2900×3500 |

|

Weight of machine |

~65 ton |

The Significance of Sludge Dryer Machine

Reduction:

Increasing the solid content of the sludge can reduce the volume of the sludge

Stability:

Municipal sludge with a solid content of more than 85% can be stored stably for a long time

Harmless:

The sludge with solid content of more than 85% can meet the US EPA-503A standards

Resource:

Municipal sludge with solid content ≥40% can meet the requirements of fluidized bed incinerator; municipal sludge with solid content ≥90% can be used as an alternative fuel

The rotary kiln incineration system we provide can be used for processing:

Hazardous waste

Industrial waste

Petrochemical waste

Medical waste

Radioactive waste

Contaminated soil

|

Item |

Design value |

Maximum value |

|

calorific value(kj/kg) |

12560~20934 |

|

|

Cl(%) |

<2 |

5 |

|

F(%) |

<0.4 |

1 |

|

S(%) |

<2.5 |

3 |

Related Issues of Sludge Dryer Machine

What other equipment is there in the waste incineration system?

Rotary lime kiln is one of the key equipments in the waste incineration system, which is also one of the best way to treat all kinds of wastes harmlessly.

CIC's rotary kiln are widely used in dealing all kinds of solid, liquid and gas wastes, including industrial wastes, chemical wastes, pharmaceutical wastes, medical wastes, contaminated soil, radioactive substances and sludge, sludge, etc.

Can you give a brief introduction to the waste treatment system of rotary kiln?

The rotary kiln incineration system is ideal for handling industrial hazardous waste. It can handle not only solid, liquid and gaseous hazardous waste, but also sludge.

We can provide a whole set of incineration equipment (including feeding system, rotary kiln, secondary combustion chamber and slag discharge system) as well as EPC services.

There are many mining machinery manufacturers, but we are one of the best choices for you.

Send product request

Other supplier products

| CIC Mining And Cement Equipment | CIC's heavy equipment and machineryinclude not only market-leading standardized products, but also customized products and related services accordi... | |

| Thrust Roller | CIC is a more than 30-year manufacturer and reputed supplier of thrust rollerused in rotary kilns, rotary type driers and so on. CIC has been speci... | |

| CIC Mining And Cement Equipment | CIC's heavy equipment and machineryinclude not only market-leading standardized products, but also customized products and related services accordi... | |

| Industrial Rotary Dryer Machine | CIC have accumulated decades of experience in the production of industrial sludge dryermachine, through continuous improvement, research and develo... | |

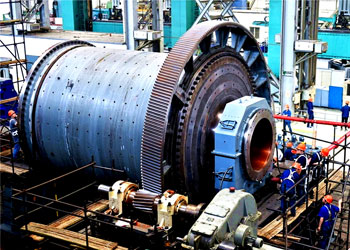

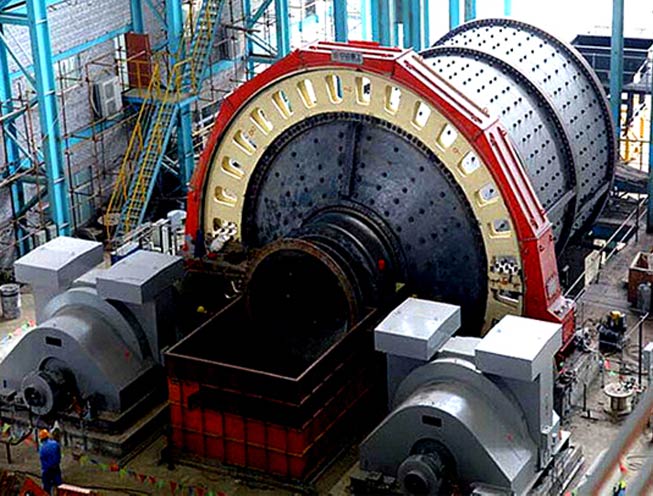

| Overflow Ball Mill | In recent years, with the continuous development of grinding technology, wet grinding has become the mainstream process, overflow type ball millis ... |

Same products

| Hydrolyzed Collagen Supplements | Seller: Zhejiang Xinmei Biotechnology Co., Ltd. | Semix organic hydrolyzed collagen peptidesis treated with alkali or acid according to different s... | |

| 5 axis machining cnc | Seller: Zooming Manufacturing inc | Zooming Manufacturing incCNC machining 5 Axis machining Precision machining machinery supplier 5 ... | |

| Wet Grid Ball Mill | Seller: CITIC IC LUOYANG HEAVY MACHINERY CO., LTD | Wet ball millis a kind of energy-saving industrial grinding mill which adopts rolling bearings an... | |

| Sludge Dryer Machine | Seller: CITIC IC LUOYANG HEAVY MACHINERY CO., LTD | CIC's sludge drying machine process was originally developed for the development of high viscosit... | |

| Tungsten carbide shims WNMG | Seller: NANF Cemented Carbide company | carbide shims P30 grade,grinding surface,with good quality. Our company is speci alized in the pr... |