STEEL TOOTH BIT

The teeth of Steel Tooth Bit are made by milling and processing of tooth wheel blanks, mainly wedge-type teeth, and the structural parameters of the teeth should be balanced to facilitate rock breaking and strength of the teeth. Generally, the tooth height, tooth width and tooth spacing are larger in soft strata, while the opposite is true in hard strata. Usually, carbide is applied to the working surface of the teeth to improve the wear resistance of the teeth, and carbide layer is applied to the back vertebrae to achieve the purpose of diameter preservation.

Different Types Of Steel Tooth Bit For Sale

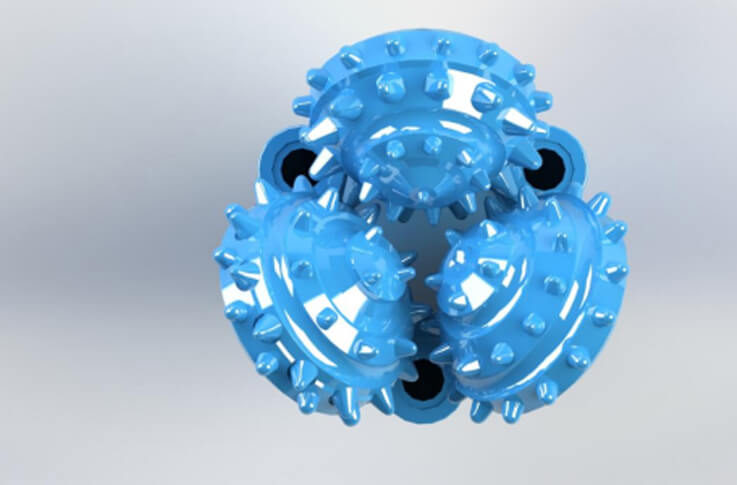

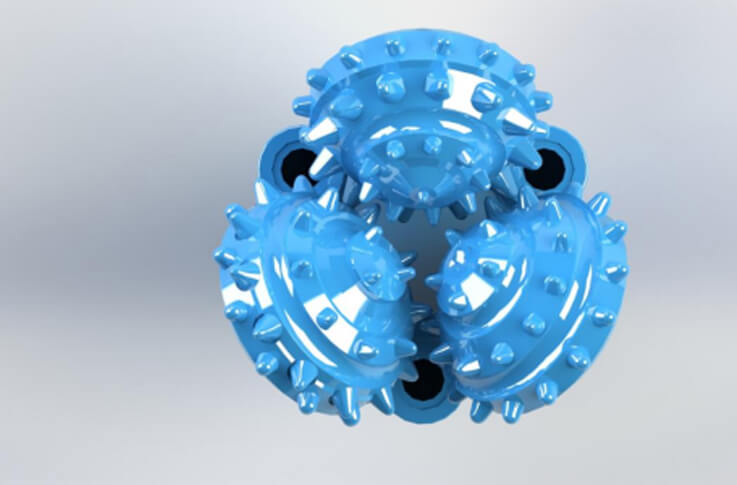

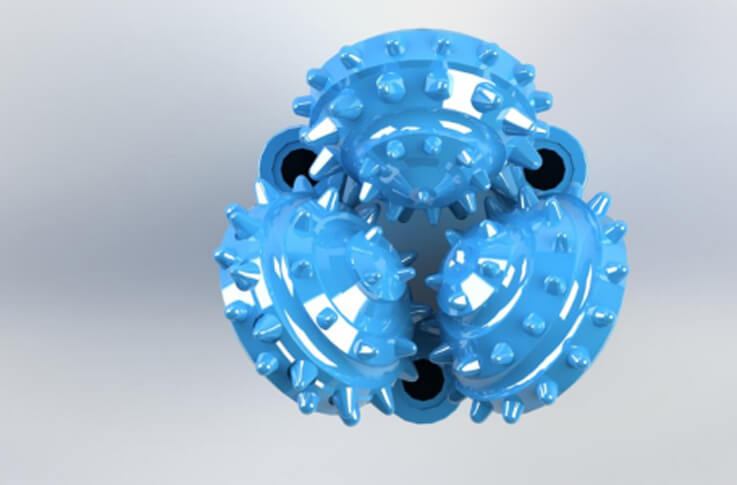

Steel Tooth Tricone Bit

Steel Tooth Bit are drilled on the tooth wheel and then teeth made of carbide are inserted into the hole.

What Strata Are Steel Tooth Bit Suitable For?

IADC517: Low compressive strength, high drillability soft strata, such as shale, clay, sandstone, soft limestone, etc;

IADC537: low compressive strength, medium soft, with hard abrasive interbeds, such as hard shale, hard gypsum, soft limestone, sandstone, dolomite with interbeds, etc.;

IADC617: high compressive strength, medium hard, with thick hard interlayer, such as hard shale, limestone, sandstone, dolomite, etc.;

IADC637: High compressive strength, medium hard and highly abrasive strata, such as limestone, dolomite, sandstone flint, etc;

The Difference Between Steel Tooth Bit And TCI Bit

TCI (carbide teeth on tooth wheel) Bits. The teeth are made of high strength and high toughness carbide teeth. The optimized design of the number of rows, teeth, height of the exposed teeth and the unique shape of the alloy teeth give full play to the high wear resistance and excellent cutting ability of the teeth. The cutting structure of the flanged drill bit has high anti-wear and load-bearing capacity, and its service life is long, especially for crushing hard and highly abrasive formations, such as tunnel stone and quartzite, etc., with better effect. The tci bit are widely used in oil drilling because they are suitable for a wide range of formations.

Steel Tooth Bits are also called milled tooth drill bits, and their teeth are milled directly on the tooth wheel blank. Steel tooth bits are mostly used in soft upper formations, but they are also used in less abrasive formations. In order to improve the wear resistance of the teeth or to make the teeth self-sharpening, a layer of tungsten carbide powder is welded on the surface of the teeth and on the diameter-keeping surface. The new wear-resistant material on the tooth surface improves the life of the cutting teeth while maintaining the high mechanical drilling speed of the steel tooth bit.

If you are looking for a reliable drill bit factory, please contact us, and we will be your best partner.

Other supplier products

|

|

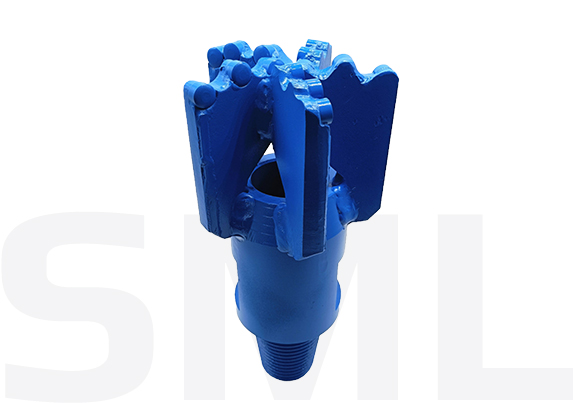

PDC DRAG BIT |

The PDC drilling drag bitis a composite of four main components: the bit body, the drag blade, the water diverter cap, and the nozzle. Forged from ... |

|

|

STEEL TOOTH BIT |

The Steel Tooth Bit teeth are crafted from milled tooth wheel blanks, primarily featuring wedge-type designs. A balanced tooth structure promotes r... |

|

|

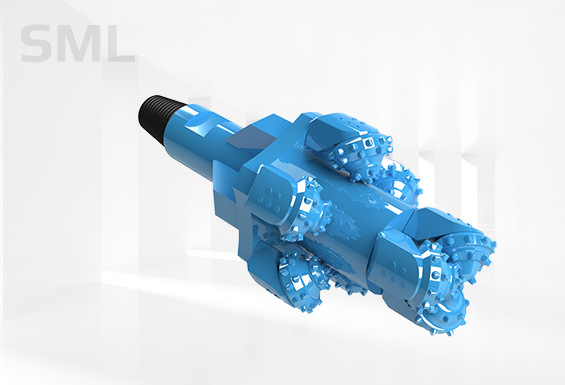

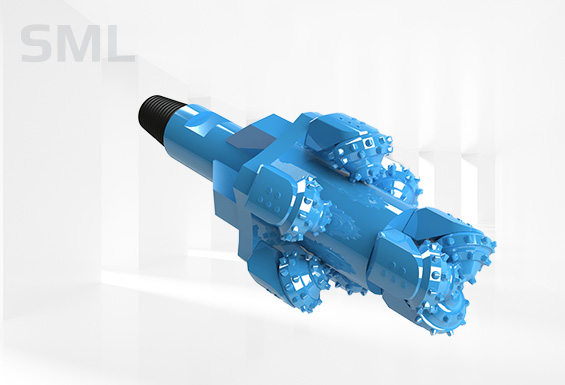

ROCK REAMER |

There is no fixed tooth shape and bearing for the hdd rock reamer, so it is necessary to select appropriate tooth shape and bearing structure accor... |

|

|

STEEL TOOTH BIT |

The teeth of Steel Tooth Bit are made by milling and processing of tooth wheel blanks, mainly wedge-type teeth, and the structural parameters of th... |

|

|

ROCK REAMER |

There is no fixed tooth shape and bearing for the hole opener bit, so it is necessary to select appropriate tooth shape and bearing structure accor... |

All supplier products

Same products