Internet Of Things PCB

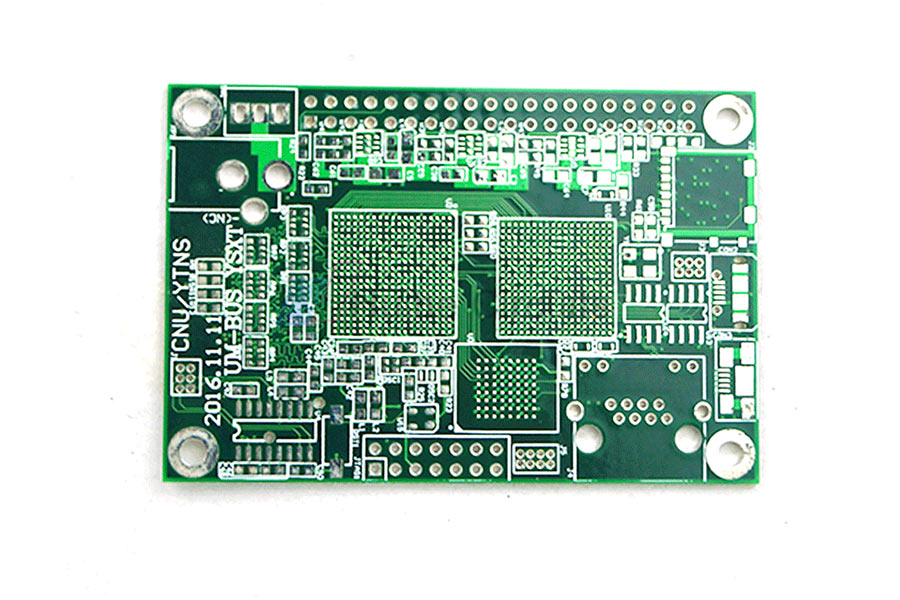

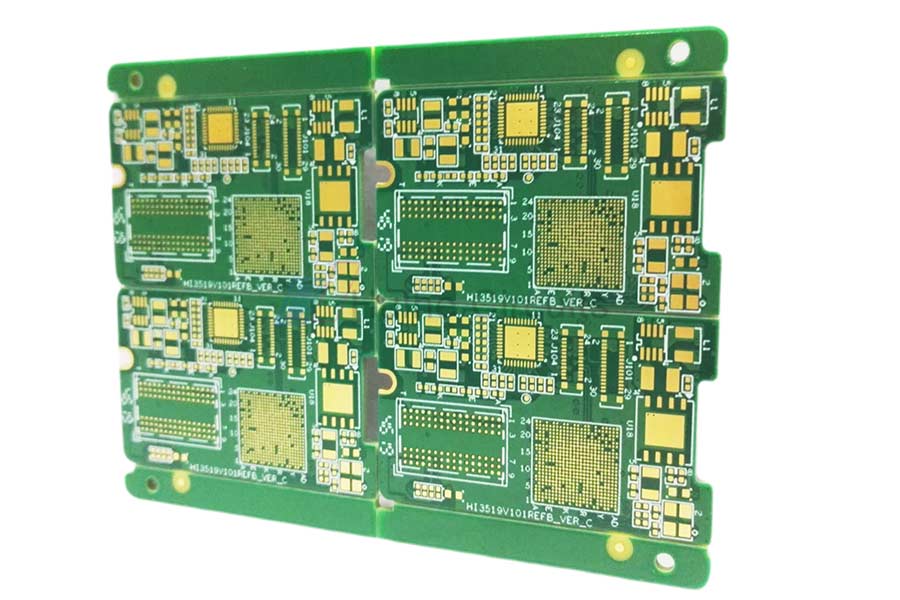

Blind and buried via PCBs used in IoT devices can place dense electronic components and flexible wiring.Blind and buried vias circuit boards use blind and buried vias to make the wiring in a limited area compact and orderly, reducing the number of layers of the PCB multilayer board.

Application Areas Of The Internet Of Things

Car Body Electronic Control System

Smart home

Smart Appliances

Smart socket

Intelligent monitoring

Smart door lock

Smart wear

Smart bracelet watch

Smart glasses

Smart clothes

Smart shoes

Smart industry

Intelligent remote control

Smart logistics

Intelligent monitoring

Smart production

Internet of Vehicles

smart transportation

unmanned

Smart parking

Smart alarm

Smart City

Smart home

smart transportation

Smart Hotel

Smart retail

Smart medical

remote diagnosis

Machine

The Advantages Of Blind And Buried Vias In The Field Of Internet Of Things

Reduced Size And Weight

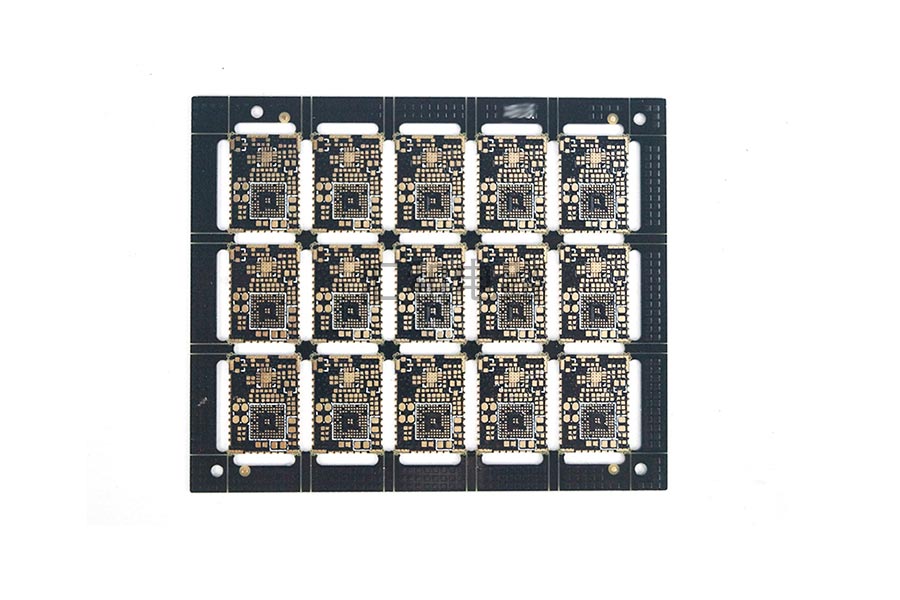

As the stacked microvia technology saves space, the layout of blind and buried via components is more compact and the circuit is more dense. Smaller circuit boards mean that PCBs can be more widely used in the field of IoT and can adapt to circuit design schemes that are updated at any time.

Simplified Wiring Path

The use of buried-blind via microvia technology makes the wiring in dense areas more uniform and reasonable, and the buried-blind via makes the wiring more selective. After circuit designers use microvias instead of vias, the signal transmission distance between components is shorter, which can improve signal integrity.

Increased Cost Effectiveness

The reduction of energy consumption and the number of layers produces more cost effects, and the smaller size enables PCB proofing and mass production to save more materials.

How Does Huihe Circuits Meet The PCB Needs Of The IoT Industry

Innovations in the Internet of Things will continue to develop at an alarming rate, and printed circuit board technology must continue to advance to meet the needs of businesses, consumers, and applications.

As the demand for PCBs is increasing and the requirements are getting higher and higher, PCBs are becoming more and more complex. For developers of IoT devices, when choosing a supplier to provide such services, they need to choose innovative Technical and experienced printed circuit board manufacturers should communicate with PCB manufacturing experts during the project start-up phase or the initial stage of circuit design.

Before quotation, Huihe Circuit’s printed circuit board manufacturing experts and engineering technical experts will review your design in advance to avoid scrap after production, save you PCBcosts or improve circuit performance. You can contact the technical team of Huihe Circuits by or to discuss the specific requirements of circuit design and circuit board production.

Huihe Circuits is a professional pcb board manufacturer, we provide iot pcb, network pcb, pcb networkand etc. For more information, please feel free to contact us!

Send product request

Other supplier products

| Heavy Copper PCB Manufacturer | Heavy Copper PCB, pcb fabrication up to 12oz, large current, pcb circuitfabrication base material is FR4/Teflon/Ceramic, pcb fabrication used in hi... | |

| Blind Buried Vias & Hdi Pcb | Buried vias PCB & blind vias PCB, use micro blind vias to increase the trace distribution density. Improve radio frequency, electromagnetic wav... | |

| 2 Layer Rogers ENIG PCB | Number of layers: 2 size: 98.45*49.45mm Surface finish: ENIG Base material: Rogers 4350B Min. hole diameter: 0.5mm Minimum Line Width:/mm Minimum L... | |

| PCB Application | As aprofessionalpcb manufacturing company, HUIHE Circuits has mastered advanced technology in the PCBindustry, we own reliable production equipment... | |

| 4 Layer ENIG Impedance Control Half Hole Fr4 PCB | Number of layers: 4 Surface finish: ENIG Base material: FR4 Outer Layer W/S: 6/3.5mil Inner layer W/S: 6/4mil Thickness: 0.8mm Special proces... |