Types Of Plastic Injection Mold Polishing

Types Of Plastic Injection Mold Polishing

Introduction to the plastic injection mold polishing

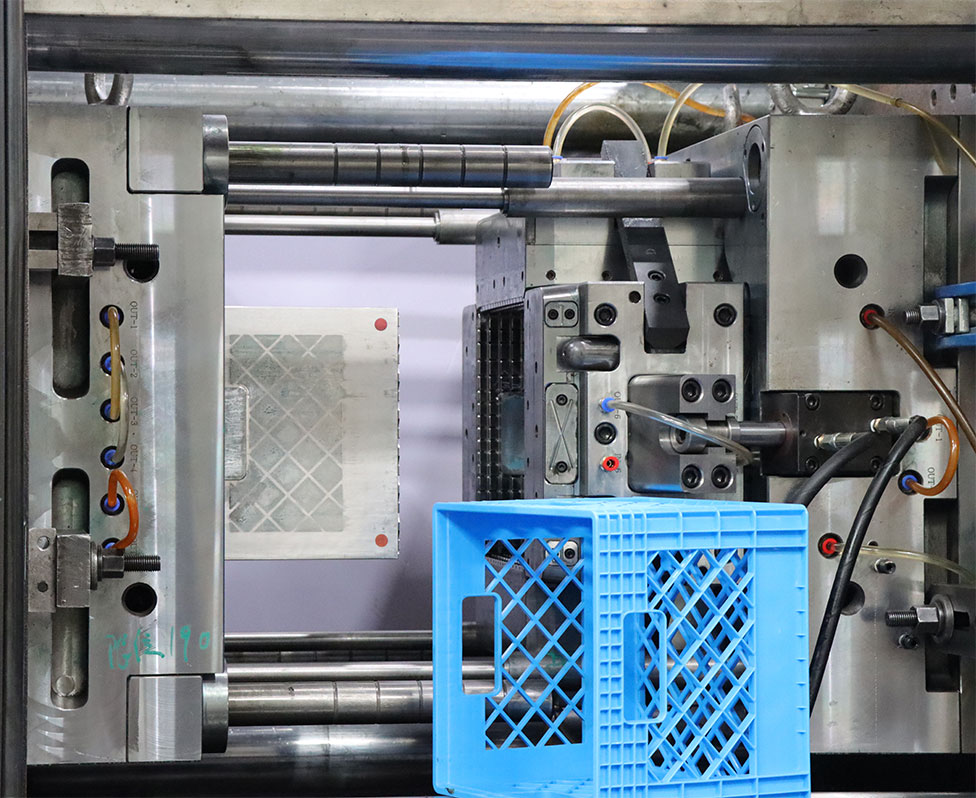

These days, industrial products are developing in the direction of product high quality as well as product diversification, in this way mold quality is going to have an influence on product quality directly, so improving mold quality has become an important task. Plasticinjection moldingpolishing is a technology that helps to obtain a smooth mold surface. It is very different from the surface treatment of other industries. It has higher standards for polishing process, smoothness, and geometric accuracy.

Types of plastic injection mold polishing service

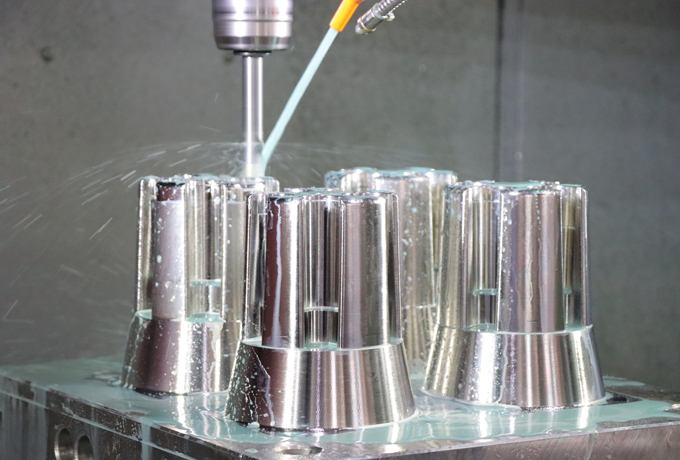

(1) Mechanical polishing

Mechanical polishing is a method of removing the protruding part on the workpiece surface by cutting or plastic deformation on the surface of the material to obtain a smooth surface. Whetstone, wool wheel, and sandpaper are usually used for manual operation; if the surface quality is high, the processes of ultra-precision grinding and polishing should be used. This technology can reach a surface roughness of Ra0.008 μm, which represents the best value for mold polishing.

(2) Chemical polishing

Chemical polishing refers to the plastic injection mold polishing process of immersing a material in a chemical medium to ensure the micro-protrusions on the surface of the material dissolve before the dents to obtain a smooth surface. The method can be used to polish workpieces with complex shapes and can polish multiple workpieces at the same time, with high efficiency. The surface roughness that can be obtained by chemical polishing is usually Ra 10 μm.

(3) Electrolytic polishing

The basic principle of electrolytic polishing is the same as that of chemical polishing, which is to selectively dissolve the surface of the material to form a smooth surface. Compared with chemical polishing, it can eliminate the influence of the cathode reaction to produce a more significant effect.

(4) Ultrasonic polishing

Ultrasonic polishing is a method that uses ultrasonic vibration of the tool part and uses abrasive suspension to polish brittle hard materials. The workpiece is immersed in the abrasive suspension, and then placed in an ultrasonic field together with the suspension, and the surface of the workpiece is ground and polished by the action of ultrasonic waves. Ultrasonic machining has a small macroscopic force, so it will not cause the deformation of the workpiece.

(5) Fluid polishing

Fluid polishing relies on the flowing liquid and the abrasive particles it carries to erode the surface of the workpiece to achieve the purpose of polishing. Hydrodynamic grinding is driven by hydraulic pressure, the polymer in the medium flows at low pressure, and the abrasive particles are usually silicon carbide powder.

(6) Magnetic grinding and polishing

Magnetic grinding and polishing of plastic molding china refer to the use of magnetic abrasives to form a brush under the action of a magnetic field to grind the workpiece. The method has high processing efficiency, good quality, and easy control of processing conditions. The surface roughness obtained by this method can reach Ra0.1 μm.

If you want to know more kinds of plastic mould polishing tools, please visit our website.

As a mold manufacturer china, we will do our best to meet all the needs of customers.

Send product request

Other supplier products

| Two Shot Molding | Two shot moulding, also called double shot injection molding, double shot moulding, multi shot injection molding or 2k injection moulding is one ca... | |

| Insert Molding | Insert MoldingService Insert molding is one category of custom injection moldingthat allows preformed parts or components, usually metal inserts, ... | |

| Plastic Injection Molding | What is plastic injection molding? Plastic Injection molding is a molding method that combines injection and molding. The advantages of plastic sma... | |

| Injection Molding | Plastic Injection Molding Plastic injection molding is a method of making plastic products. The molten plastic is injected into the mold by pressu... | |

| Plastic Injection Mould Tooling | Plastic molds are tools that are matched with plastic mold makingmachines in the plastic processing industry to give plastic products a complete co... |

Same products

| PTFE Film | Seller: Jiangsu Xinrui Plastic Technology Co.,Ltd | Polytetrafluoroethylene filmis made of PTFE resin by molding, sintering, cooling into blank, then... | |

| Types Of Plastic Injection Mold Polishing | Seller: Taizhou Huangyan Fow Mould CO., LTD | Types Of Plastic Injection Mold Polishing Introduction to the plastic injection mold polishing ... | |

| Two Shot Molding | Seller: Taizhou Huangyan Fow Mould CO., LTD | Two shot moulding, also called double shot injection molding, double shot moulding, multi shot in... | |

| PRECISION PLASTIC INJECTION MOLDS/TOOLS | Seller: Dongguan City Fangling Precision Mould Co., LTD. | When it comes to plastic injection mold parts, precise moulds and precision equipment are require... | |

| Indoor Slippers | Seller: Good Seller Co., Ltd | After a tired day, your customers need comfortable indoor slippersto keep feet cozy around house.... |