Fortune cookie

1. Fortune Corporation - the ONLY professional industrial fortune cookie manufacturer in Russia.

2. Our partners - the leading manufacturers in the U.S., Japan and France.

3. 10 thousand positive universal predictions in Russian (suitable for any holiday, event, events).

4. At present we produce complex robotic 20 million cookies per hour. (See video) on . Therefore, all the cookies are always available.

5. We use cookies to prepare high-quality ingredients: flour, including to / from King Arthur Flour (USA), olive oil Extra virgin (Spain), butter Lurpak (Denmark), eggs (including quail), fresh fruit and vegetables, dyes and fragrances.

6. The composition is developed by order of our American partners in the special food ingredients Laboratory (USA-California).

7. Edible paper and paint to the predictions made in Japan. Printed in the specialized press in Europe.

8. In individual package for all the fortune cookies we use only two-layer printed film between the layers of the paint does not touch the cookies. This package is fully consistent with the highest international standards.

9. All of our products are GOST Certificate, Declaration of Conformity, the bar code.

Send product request

Other supplier products

| Fortune cookie | 1. Fortune Corporation - the ONLY professional industrial fortune cookie manufacturer in Russia. 2. Our partners - the leading manufacturers in the... |

Same products

| Knife Tabletop Electric Noodle Press | Seller: Yongkang Haiou Electric Co., Ltd. | This series is a series of electric noodle machine without removing knife, which is more convenie... | |

| Wheat Flour | Seller: SZK | ||

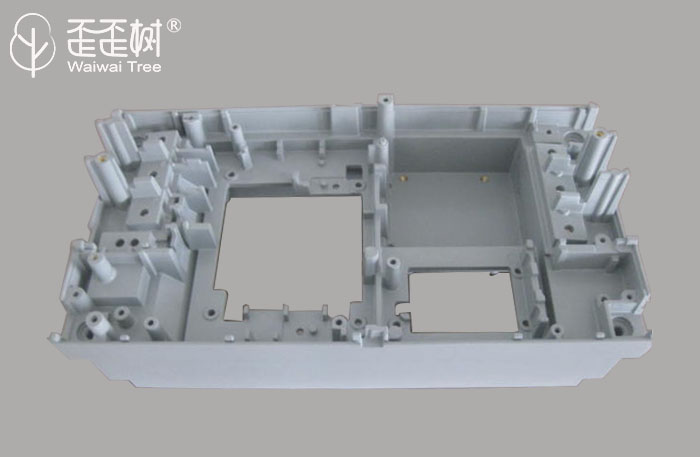

| SMC/BMC Framework | Seller: ZHEJIANG AOBANG TECHNOLOGY CO.,LTD | SMC/BMC Framework Description Strong plasticity, precise size, high insulation and high temper... | |

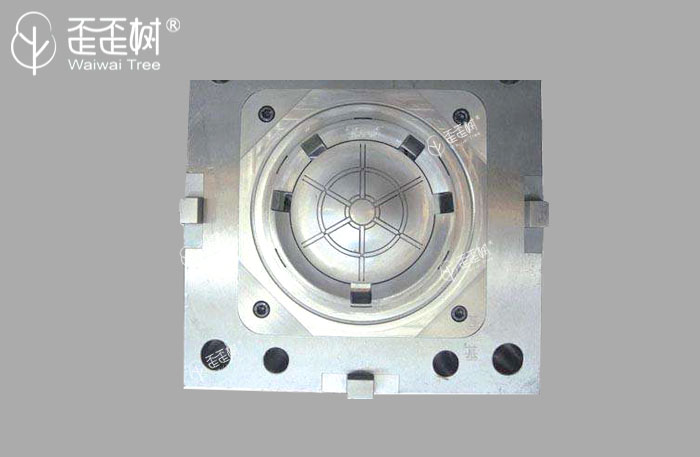

| Shell Moulding | Seller: ZHEJIANG AOBANG TECHNOLOGY CO.,LTD | Shell Moulding Description BMC/SMC shell moulding is mainly injection molded. The application of... | |

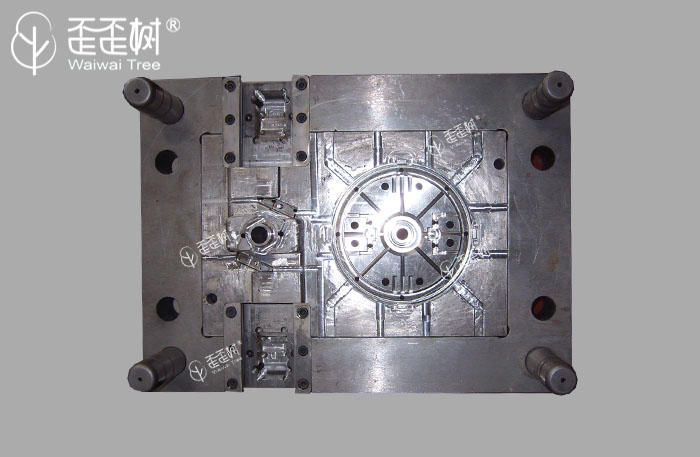

| Motor Mold | Seller: ZHEJIANG AOBANG TECHNOLOGY CO.,LTD | Mainly for injection molding, the design of the runner and the parting surface should be as small... |