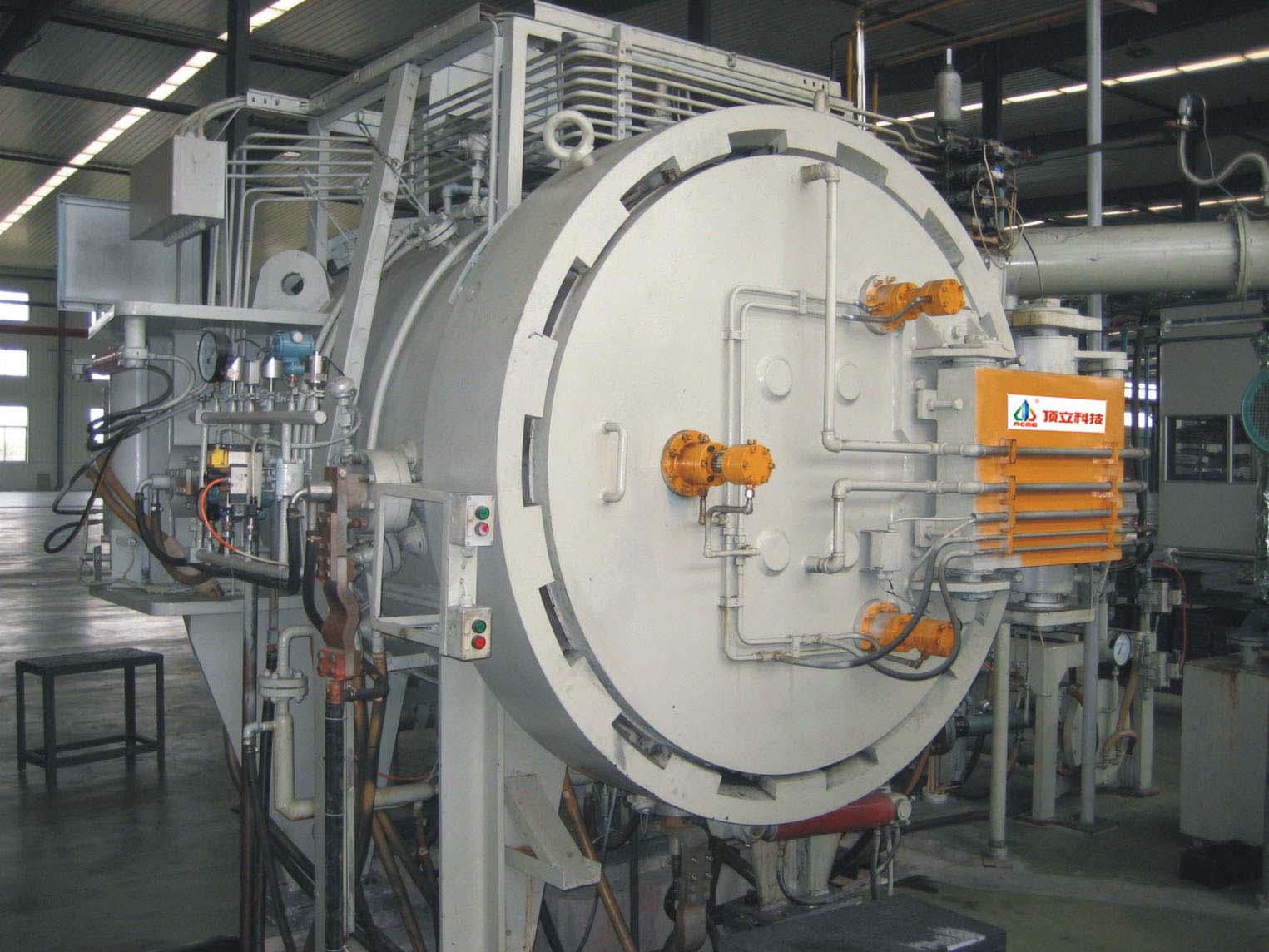

Reduction Furnace Manufacture

Description

Steel belt furnace is mainly applied for reduction of Fe powder, Cu powder, Co powder, Ni powder, W powder, Mo powder, etc. It can also used for calcination of metal salt like cobalt formate and APT.

Technical Features

1. Continuous production features low energy consumption and large production capacity.

2. The furnace without boat and dead corner ensures good temperature uniformity, complete reduction and high quality.

3. Steel belt reduction furnaces are configured with full automatic loading and unloading operation, which makes stable product quality and low labor force.

4. The furnace is equipped with gas recycle system, which can improve the gas efficiency and lower the gas consumption.

5. It has functions of remote control operation, remote malfunction diagnosis and remote program update functions.

Other supplier products

|

|

Induction Heating Furnace |

Induction heating furnace is mainly applied for high temperature graphitization treatment of C/C, graphite, carbon fiber insulation refractory mate... |

|

|

Pressure Sinter (Sinter-Hip) Furnace |

DescriptionPressure sinter furnace is mainly suitable for sintering and pressure sinter processes of tungsten alloy, magnetic, heavy alloy, moly al... |

|

|

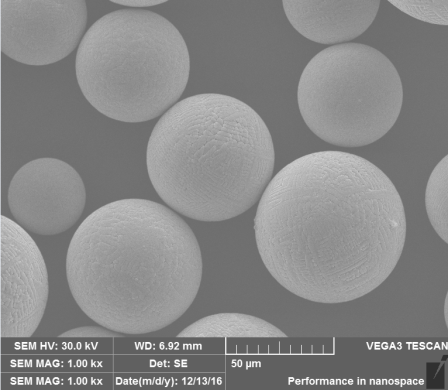

Spherical Cobalt-based Alloy Powder |

Based on technology innovation and professional service, ACME provides high-end industrial heating equipment for customers in various fields, such ... |

|

|

Vertical Bottom Loading Vacuum Brazing Furnace |

DescriptionVacuum bottom loading furnace is used for vacuum brazing of materials like non-ferrous metal, stainless steel, titanium alloy, high temp... |

|

|

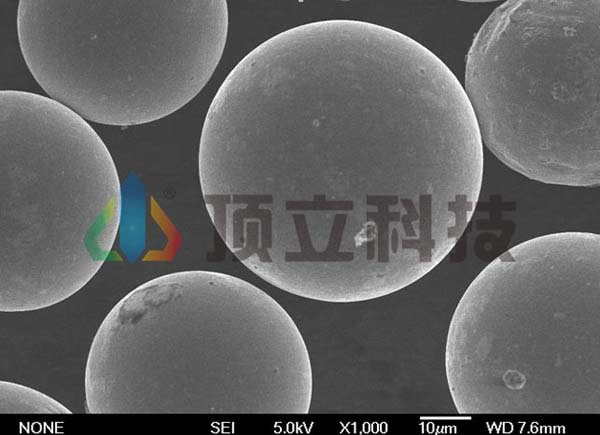

Spherical Aluminum Alloy Powder |

Based on technology innovation and professional service, ACME provides high-end industrial heating equipment for customers in various fields, such ... |

All supplier products

Same products