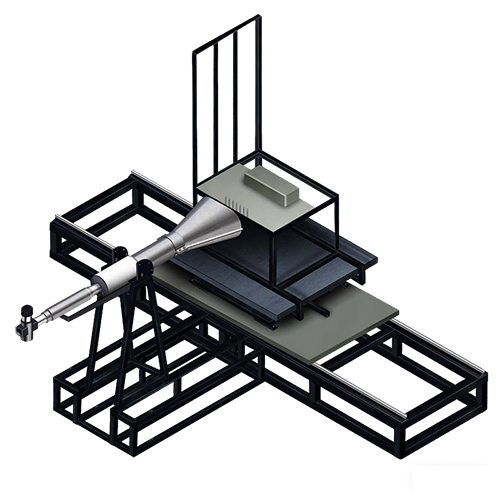

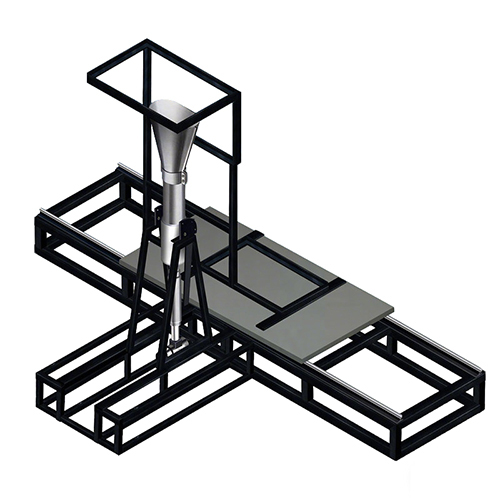

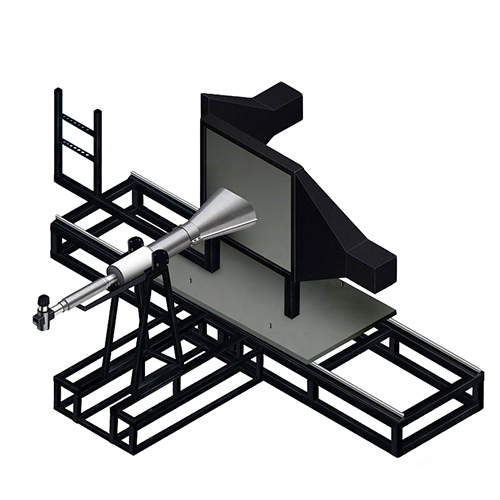

Mesh Belt Sinter Furnace

Description

Mesh belt sinter furnace is mainly used for high temperature sinter of powder metallurgy ferrous and copper parts, such as oil bearing, gear, clutch plate, bushing, sleeve, etc.

Technical Features

1. The furnace is configured with RBO rapid binder removal system as required.

2. Module type heating element is used , which is convenient for maintenance and replacement without stop the furnace.

2. All fiber refractory structure guarantees faster heating rate and less energy consumption.

3. Mesh belt sintering furnace uses hanging roof structure, which is convenient for maintenance and replacement of muffle.

4. Fast cooling system is available that is mainly for hardening the ferrous material.

5. It has functions of remote control operation, remote malfunction diagnosis and remote program update functions.

Send product request

Other supplier products

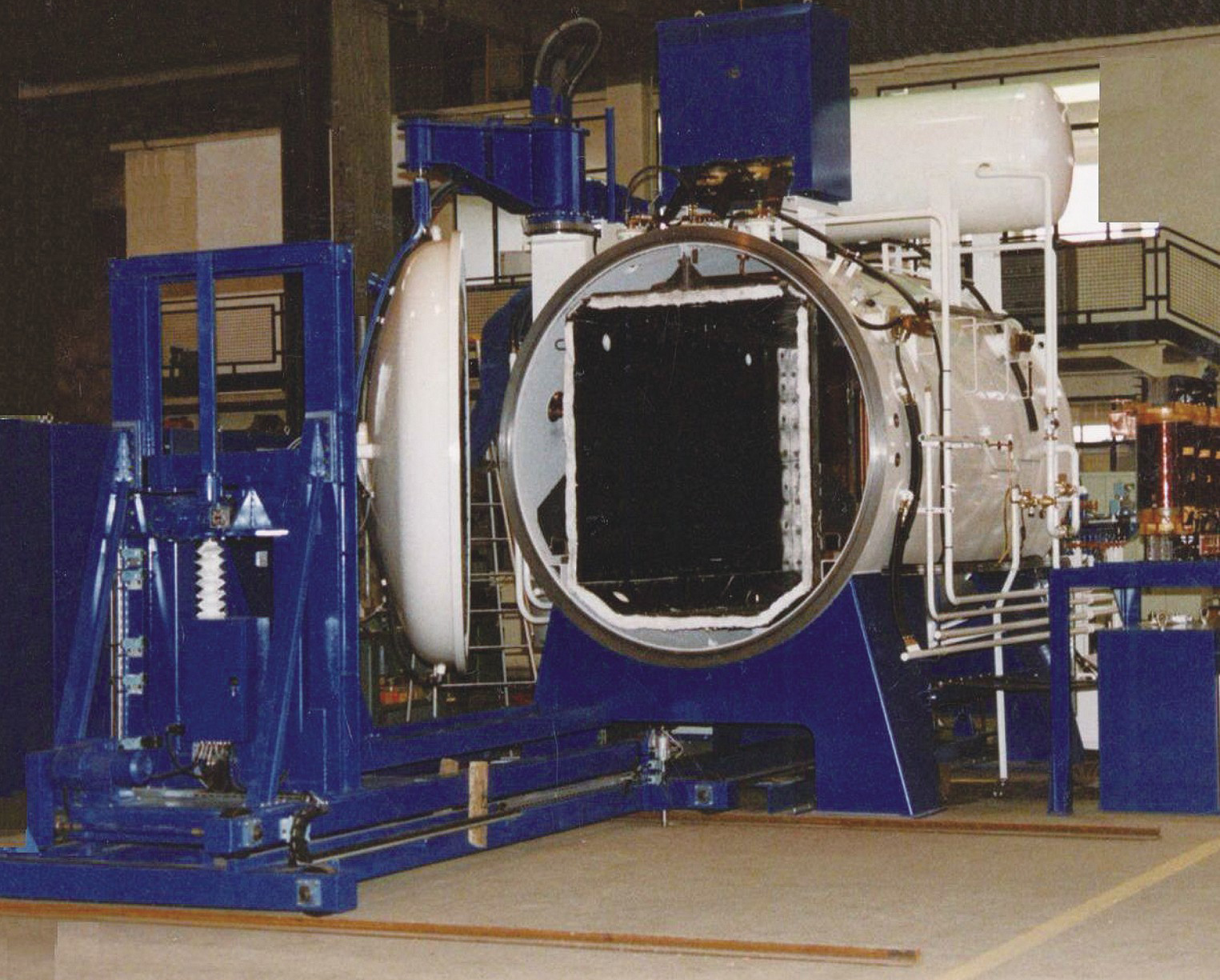

| High Vacuum Aluminum Brazing Furnace | DescriptionHigh vacuum aluminum brazing furnace is applied for vacuum brazing of materials like heat exchanger, air condition evaporator, condenser... | |

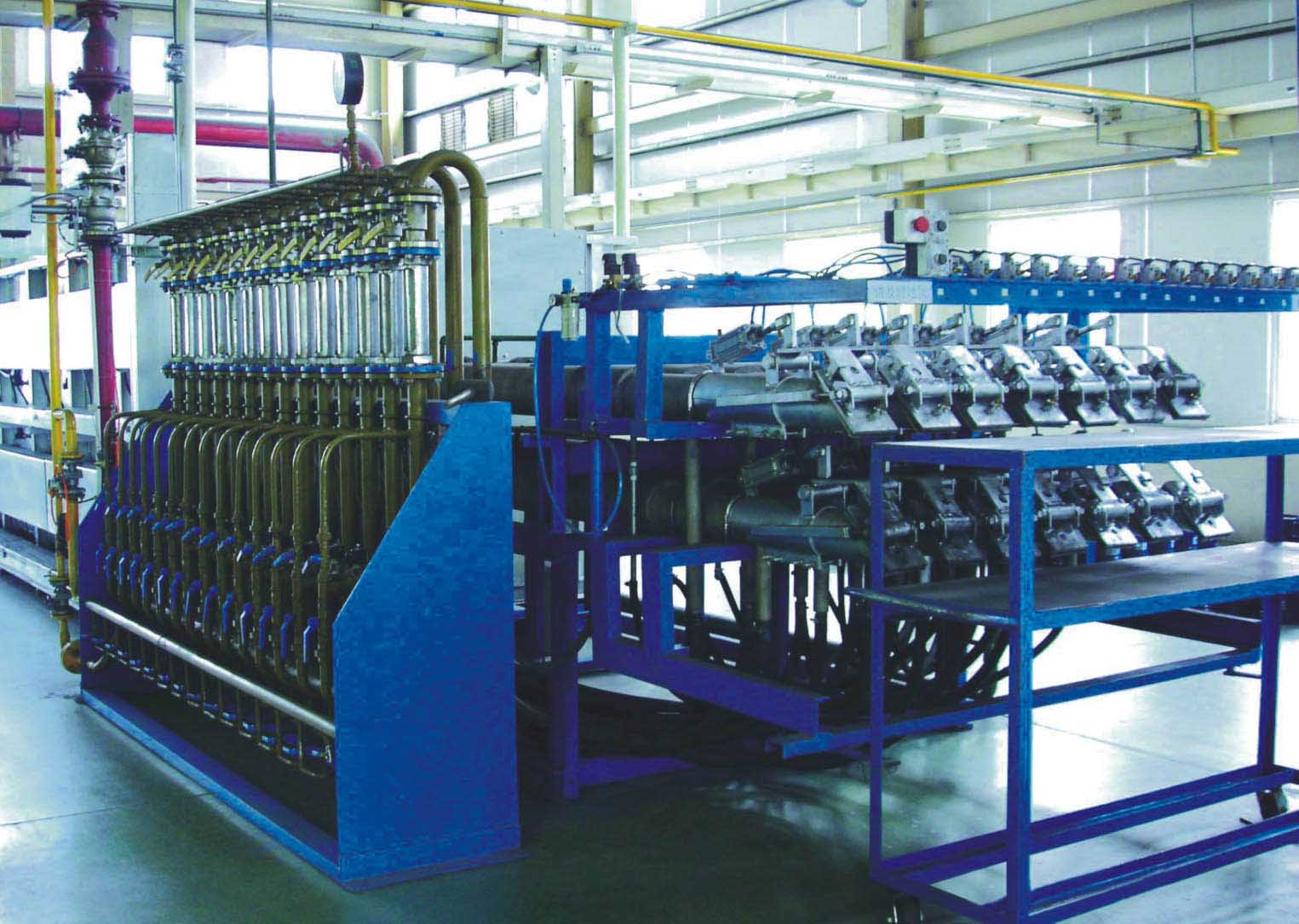

| 18-Tube Automatic Reduction Furnace | DescriptionMulti-tube furnace is mainly used for metal powder (like tungsten, moly, etc) reduction.Technical Features1. Multiple tube heating guara... | |

| Horizontal Twin Chamber Vacuum Oil Quenching Gas Cooling Furnace | DescriptionThe vacuum oil quenching furnace is suitable for vacuum oil quenching of materials like alloy steel, bearing steel, spring steel, die st... | |

| Vacuum Debinding and Sinter Furnace | Vacuum debinding and sinter furnace is mainly suitable for debinding and sinter process of tungsten alloy, heavy alloy, moly alloy, titanium alloy ... | |

| Horizontal Single Chamber Vacuum Annealing Furnace | DescriptionHorizontal vacuum annealing furnace is applied for bright annealing of materials like tool steel, die steel, high speed steel, ultra-str... |