Gas cylinder air tightness testing machine

Gas cylinder air tightness testing machine is in accordance with the requirements for G B12137 for bottles, valves and plug the place such as thread inspection whether leak. The role of this device

After filling is the cylinder on the framework, using cylinder lifting and lowering, reasonable structure, simple operation, suitable for gas cylinder manufacturers and gas cylinder test

The use of test stand.

Working principle of the

Gas tightness test using liquid flooding gas compressor, large diameter liquid driven piston structure with small diameter piston is connected to the pressure.

Using the area ratio of two piston pressure ratio, pressure ratio can be calculated through the maximum output pressure. Work, to drive the piston to the high-pressure plunger end counter

To exercise, one-way valve open, at the entrance of the exit check valve closed, the gas inside the suction pump. When piston backward movement, at the side of the media will shape

With a certain pressure, the pressure inlet one-way valve will be closed, the exit check valve opens, the high pressure gas output. Through a three liquid flooding gas compressor

Four electrohy-draulic reversing valve and a relief valve realize the reversing.

Main technical parameters of liquid flooding gas compressor

Drive cylinder diameter: 125 mm

Pressurized cylinder size: 80 mm

Cheng: 150 mm

Single stroke displacement: 0.75 L

Reciprocating frequency: 30 times/min

Increased compression ratio: 2.25:1

Hydraulic pump pressure rating: 16 mpa

Pre pressurization gas: 3 mpa 1.0 Nm3 / min

Power supply voltage, ac 380 v

Supercharging system control system: PLC control, manual control

Bleed air filling process

1. Medium pressure air compressor as intake pre pressurization gas, liquid flooding gas compressor, to the inflatable bottle group, to set pressure.

2. Bottles of bottles of fast charging - of the test, pressure balance, start the fluid displacement compressors, using the bottle group as into the air fast inflatable bottle of the test to test

Test pressure.

3. Start the liquid flooding gas compressor, the test bottle to bottle group quickly back to the gas drainage, to test the pressure in the bottle is close to zero.

Description: gas tank vent for the longest part is a inflatable bottle group, but the process could be at work in advance. And the process

Pour bottle way, high-pressure gas always cycle back and forth between the group with the test bottles, only a few gas loss, so we can ensure testing bottle in a very short

Complete filling is deflated.

Main technical parameters

Model: the QPC - 01

(1) work test pressure: 20 mpa

(2) working efficiency: 5-12 only an hour

(3) the air pressure: 0.6-0.8 MPa

(4) cooling, water cooling

(5) output pressure: 0 to 30 MPa

(6) capacity: 0.6 m3 / min

Other supplier products

|

|

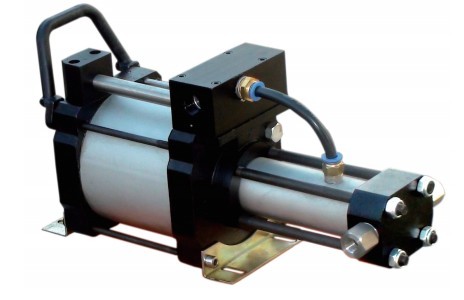

STD series air drive gas booster pump |

S T D series gas booster pump for single-stage booster pump, to achieve the required pressure gas input port input pressure require a certain degre... |

|

|

PSАseries air drive gas booster pump |

PSАseries air drive gas pump and the non-equilibrium gas distributing valve to achieve the reciprocating movement of the pump, all adopt the alumin... |

|

|

Four pillar type punching machine |

Four pillar type punching machineCPB/CPBG seriesThe basic component ofL four-post type stamping the bodyL force of gas liquid cylinder(my company H... |

|

|

Gas cylinder pressure tightness test machine |

An overview of theGas cylinder pressure tightness test machine is in accordance with the requirements for G B12137 for bottles, valves and plug thr... |

|

|

Blasting test bench is (pressure) |

Blasting test bench is (pressure)

Our company based on pneumatic supercharging device

Working principle, combines the actual conditions of our cou... |

All supplier products

Same products