AUTOMATION EQUIPMENT FOR KITCHENWARE INDUSTRY

For the kitchenware industry, we have developed the welding and forming production line of G-shaped stainless steel ring for glass pot cover, the welding and forming production line of steamer stainless steel belt, the welding and forming production line of net basket, the welding and forming production line of C-shaped ring for enamel pot, etc. The equipment carries out laser seamless welding on stainless steel strip through laser continuous welding technology. According to the product size requirements of the respective factories, customized molding molds enable welding molding to realize automatic production, which greatly improves the production efficiency and reduces the production cost.

DIFFERENT TYPES OF AUTOMATION EQUIPMENT FOR KITCHENWARE INDUSTRY FROM XIHE

01

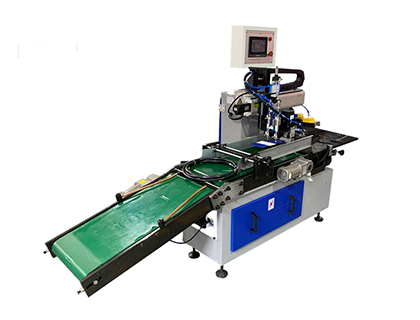

Pot Cover Production Line

The pot cover production line is an automatic production line formed by automatic production of welding, crimping, stretching, chamfering, pressing and other processes.

02

Food Steamer Production Line

Adopt advanced laser continuous welding technology, exquisite appearance design, and accessories adopt world-renowned brands.

03

MeshBasket Production Line

The combination of four-station forming and laser continuous welding technology is the best choice for the production of mesh baskets.

04

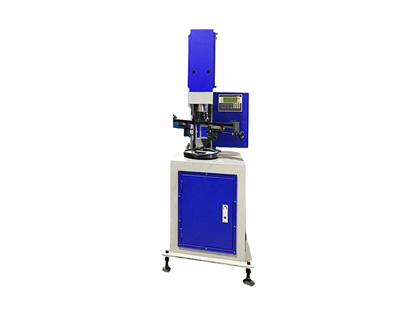

Enamel Lid Production Line

Combined with the characteristics of the C-shaped ring of the enamel pot, the robot arm is used to grab the workpiece to quickly complete the welding and forming of the C-shaped ring.

HOW DOES AUTOMATION EQUIPMENT FOR KITCHENWARE INDUSTRY WORK?

The equipment is mainly used for the automatic production of welding and forming of C-shaped small circles such as enamel cans. The material is fed by the driving wheel, then wound around the round.

ADVANTAGES OF AUTOMATION EQUIPMENT FOR KITCHENWARE INDUSTRY

1

The equipment is mainly suitable for laser welding of stainless steel bars in glass pot lids, mesh baskets, enamel jars, trash cans, paper buckets, sieves and other industries.

2

Using laser continuous welding technology, it is formed through custom molds. The equipment uses a touch screen to control operating parameter settings and is suitable for producing stainless steel rings of various widths, thicknesses and diameters.

3

For laser seam welding, it solves various production problems such as weak welds, uneven welds, unsightly welds and wasted material.

Now the price of kitchen automation equipmentis affordable, anything you need, please contact us.

If you want to know more kinds of laser welding system, please visit our website.

Send product request

Other supplier products

| STAINLESS STEEL WELDING MACHINE | Laser welding machine for stainless steeladopts laser continuous welding technology, high-precision servo motor feeding, high-speed clamping and ot... | |

| AUTOMATIC POLISHING MACHINE FOR STAINLESS STEEL BELT | The equipment uses two methods of duplex position vertical and horizontal for cylindrical polishing to meet the product brightness and smoothness; ... | |

| ENAMEL POT STAINLESS STEEL BELT CRIMPING MACHINE | ENAMEL POT STAINLESS STEEL BELT CRIMPING MACHINE The equipment is designed for automatic crimpingand forming after welding of stainless steel ring... | |

| AUTOMATIC POLISHING MACHINE | Theconcrete grinding and polishing machine, also known as the automatic polishing machine, is a state-of-the-art piece of equipment that utilizes a... | |

| PAPER DRUM STAINLESS STEEL BELT CRIMPING WELDER | PAPER DRUM STAINLESS STEEL BELT CRIMPING WELDER This equipment is designed for crimping and forming after welding of paper drum stainless steel ri... |

Same products

| MECHANIC 10cc Solder Paste Flux for Mobile Phone SMT PCB Soldering | Seller: Phonefix | MECHANIC Syringe Solder Paste (Sn63/Pb37) for mobile phone BGA and SMT repair. This 10cc tin past... | |

| YCS M.Y 140/160/183/199°C Solder Paste for Phone PCB IC Repair | Seller: China PHONEFIX Technology Co., Ltd | Description YCS M.Y-XJ01 140°C 160°C 183°C 199°C Solder Paste for mobile... | |

| MECHANIC T210 SE Digital Soldering Station for Precision PCB and Chip-Level Repair | Seller: Phonefix | Mechanic T210 SE 50W Digital Display Thermostatic Soldering Station supports C210 soldering iron ... | |

| SUNSHINE SS-6604 SS-6605 Soldering Smoke Purifier Fume Extractor | Seller: China PHONEFIX Technology Co., Ltd | Description SUNSHINE SS-6604 SS-66045 Fume Purifier Smoke Absorber for mobile phone repa... | |

| MECHANIC M35 Flux Paste for Phone Motherboard Repair | Seller: Phonefix | The Mechanic M35 10CC Nano Flux Paste offers 98% new high activity. This high-efficiency, synergi... |