Molybdenum Crucible

Molybdenum crucibleis a container made from molybdenum metal used for high-temperature applications in industries such as aerospace, energy, and electronics. It has a high melting point, good thermal conductivity, and high strength at elevated temperatures. Molybdenum crucibles are ideal for melting and casting metals, as they can withstand extremely high temperatures and resist attack from most chemicals. They are available in different sizes and shapes to accommodate various requirements.

Molybdenum (Mo) Crucibles Advantages

Molybdenum crucibles offer several advantages over other materials that make them an ideal choice for high-temperature melting, casting, and annealing processes. Here are some of the benefits of using molybdenum crucibles:

High melting point: Molybdenum has a high melting point of 2,623°C, making it suitable for high-temperature applications where other materials would melt or deform.

Excellent thermal conductivity: Molybdenum has excellent thermal conductivity properties that ensure even heating of the material being melted.

Chemical resistance: Molybdenum is highly resistant to chemicals and does not react with most acids, alkalis, or other corrosive substances.

Low thermal expansion: Molybdenum has low thermal expansion properties that allow it to maintain its shape and resist warping during high-temperature applications.

Durable and long-lasting: mo crucibles are durable and long-lasting, offering excellent performance even after repeated use.

Resistant to oxidation: Molybdenum is highly resistant to oxidation, ensuring that it does not contaminate the materials being processed.

Cost-effective: Molybdenum crucible priceis more economical compared to other high-temperature resistant materials such as platinum.

In summary, molybdenum crucibles offer several advantages over other materials, such as high melting point, chemical resistance, and durability. These advantages make them suitable for a wide range of high-temperature applications in various industries and a popular choice for material processing.

Molybdenum Crucible Operating Principle

Molybdenum crucibles function based on the principle of metallurgical composition and high-temperature resistance. Molybdenum metal has a high melting point of 2,623°C, making it well-suited for applications involving high-temperature melting and casting. The molybdenum crucible is designed to withstand these high temperatures and the harsh environment of melting and casting processes.

During the melting process, the molybdenum crucible is placed inside a furnace and loaded with the material being melted. As the temperature of the furnace increases, the material inside the crucible starts to melt, and the molybdenum crucible maintains its shape.

Molybdenum crucibles are also commonly used for sintering and heat treatment applications. In these cases, the crucible is loaded with the material to be sintered or heat-treated and placed inside a furnace. The molybdenum crucible functions as a container that holds the material, while the high-temperature environment creates the desired sintering or heat treatment effects.

In summary, the operating principle of molybdenum crucibles is based on their high-temperature resistance, which allows them to withstand the extreme heat generated during melting, sintering, and heat treatment processes. The crucibles are designed to maintain their shape and integrity in these harsh conditions, allowing for safe and reliable material handling and processing.

Application Areas of Molybdenum Crucibles

Mo crucibles from molybdenum crucible suppliers are used in various applications that require high-temperature resistance and good thermal conductivity. Some of the areas of application include:

Aerospace: Molybdenum crucibles are used to process and manufacture aerospace materials such as superalloys, titanium alloys, and carbon fiber composites.

Metallurgy: Molybdenum crucibles are used in metallurgical processes for melting and casting metals and alloys such as copper, iron, nickel, silver, and gold.

Electronics: Molybdenum crucibles are used in the electronics industry for the manufacture of semiconductors, as well as high-temperature materials such as tungsten filament, sputtering targets, and X-ray tubes.

Chemical processing: Molybdenum crucibles are used in chemical processing, especially in the manufacture of chemicals and catalysts.

Glass manufacturing: Molybdenum crucibles are used in glass manufacturing industries for melting glass.

Medical equipment: Molybdenum crucibles are used in the production of medical instruments, implants, and other medical equipment.

Research and development: Molybdenum crucibles are also used in research and development laboratories for various high-temperature applications.

In summary, molybdenum crucibles are used in a wide range of industries and applications that require high-temperature resistance, excellent thermal conductivity, and durability.

We can also offer sorts of industrial air coolerproducts for sale, if you are interested, please leave us a message.

Send product request

Other supplier products

| Direct Air Cooled Condenser (ACC) | Direct acc air cooled condenser (ACC) is a type of heat exchanger commonly used in thermal power plants. It is designed to convert steam from the t... | |

| Molybdenum Screw. | Molybdenum screwis a fastener made of molybdenum, a refractory metal with excellent strength, corrosion resistance, and thermal stability. Molybden... | |

| NEW ELECTRONIC MATERIALS | New electronic materialsform the building blocks for the electronics industry. These materials are essential for the manufacture of electronic devi... | |

| Luoyang CBD, No.288 of Kaiyuan Avenue, Luoyang, Henan, China | Copper extractants are organic compounds used to selectively extract copper ions from ores and concentrates. They form chemical complexes with copp... | |

| Plate Heat Exchanger | Plate Heat Exchanger Plate heat exchanger for refrigerationis a highly efficient phe heatexchange system comprised of a series of metal sheets wit... |

Same products

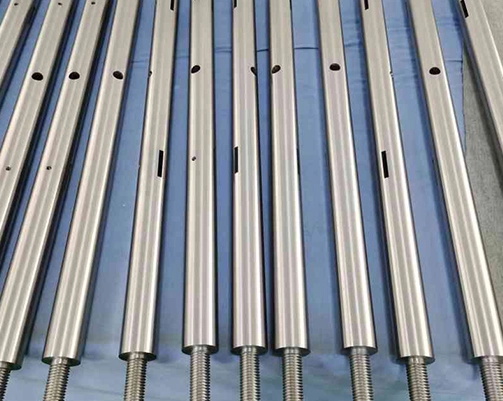

| Molybdenum Rod Supplier | Seller: Baoji City Changsheng Titanium Co.,Ltd | Grade: Mo1 Mola TZM Standard: GB/T4188-1984 Surface condition: Black, Alkali wash, Bright, ... | |

| Double Side Manual Decoiler | Seller: Hangzhou Roll Forming Technology Co.,Ltd | Specifications ofDouble Side Manual Decoiler Type Double side Capacity ... | |

| Double Layer Roll Forming Machine | Seller: Hangzhou Roll Forming Technology Co.,Ltd | Double layer cold roll forming machine, also called double deck roll forming machine. To meet the... | |

| Molybdenum Crucible | Seller: Longhua Technology Group (Luoyang) Co., Ltd | Molybdenum crucibleis a container made from molybdenum metal used for high-temperature applicatio... | |

| SST125 Spider Machine for Socket Fusion Welding | Seller: HEBEI MINGMAI TECHNOLOGY CO.,LTD | SST125 Spider Machine for Socket Fusion Welding Connect Type:Socket Fusion Fix range:63-125mm For... |