Metallurgical Furnace

CIC main advantage in nonferrous metallurgical furnacelies in the manufacture of horizontal rotary furnace, Rotary refining furnace and bottom blown furnace. Rotary furnace is the main metallurgy furnace equipment used to treat copper and nickel sulfide in nonferrous metallurgical production. The rotary furnace does not need fuel, and only relies on the heat released by the oxidation reaction of iron and sulfur in copper and sulfur with the air blown into the heavy equipment and machinery solution to provide all the heat expenditure.

Instruction of Metallurgical Furnace

Rotary refining furnace is mainly used for refining liquid crude copper and copper mining process. The refining operation generally includes four stages: feeding, oxidation, reduction and casting. The product is to provide a qualified anode plate for copper electrolytic refining. Therefore, rotary refining furnace is also called a rotary anode furnace.

The main characteristics of rotary refining furnace are simple structure, large furnace capacity, high degree of mechanical automation, strong controllability, good sealing and low energy consumption. Rotary refining furnace is mostly used in pyrometallurgical refining of large or extra large copper smelters.

Structure of Metallurgical Furnace

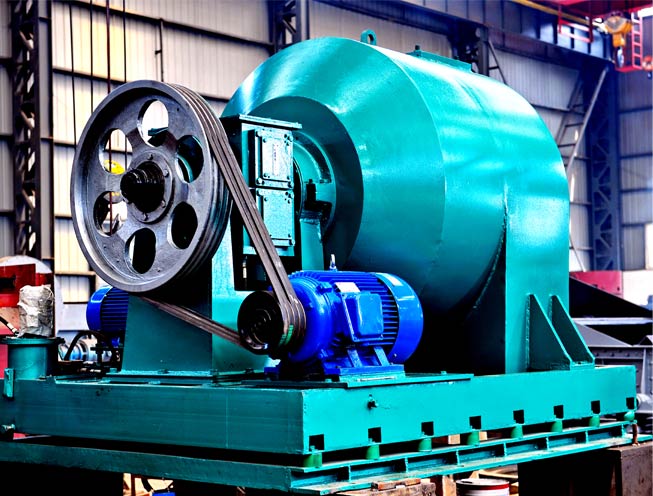

The horizontal rotary furnace is a kind of smelting equipment for blowing matte or nickel into coarse copper or high matte in the smelting process of non-ferrous metals such as copper and nickel. Its specification is expressed by the output of each furnace. The furnace body is cylindrical (see Fig. 1), and a furnace mouth is set in the middle for charging, smoke exhaust, slag discharge and discharging. A row of tuyeres is set at the furnace side along the horizontal direction to blow in the air. The lining of the horizontal converter is made of magnesia or chrome magnesia refractory.

Rotary refining furnace is mainly composed of furnace body, supporting device, drive and control system. The main supporting equipment includes combustion device, combustion air system, oxidant, reductant, steam, compressed air, cooling water and process piping (as shown in Figure 2 below).

The cylindrical furnace body is provided with a furnace mouth for charging and discharging copper. The furnace mouth is equipped with a furnace cover. The furnace cover is only opened when charging and discharging copper. The melting period, oxidation period and reduction period are all covered. A small amount of tuyere is set on the side of the furnace body, high-pressure air is introduced in the oxidation period, and the reducing agent is introduced in the reduction period. When the tuyere is not in operation, it is placed above the melt surface. When the redox operation is carried out, the furnace is tilted to make the tuyere embedded in the melt. The rotary refining furnace needs an external heat supply, so it is equipped with a fuel combustion device and exhaust port.

Send product request

Other supplier products

| Horizontal Centrifuge Machine | TWZ series horizontal vibratory centrifuge belongs to the centrifugal dewatering machine, the series of horizontal vibratory centrifuge is mainly u... | |

| Furnace Tapping Machine | + We developed the discharge furnace robotic arm machine, based on the working process and tools of manual operation of slag port opening and clos... | |

| Cement Rotary Kiln | Cement Rotary Kiln Since 1950s, CIC rotary kiln manufacturerhad started manufacturing of pyro processing equipment. These series of pyro processin... | |

| CIC Customized Cement Grinding Mill and Rotary Kiln for Cement | As a kind of building material, cement is widely used with large demand and fierce competition in the industry. As the leader of cement production... | |

| Dry Ball Mill | Dry ball millis suitable for all kinds of metal and nonmetal ores, including materials that will react with water, such as cement, marble, and othe... |

Same products

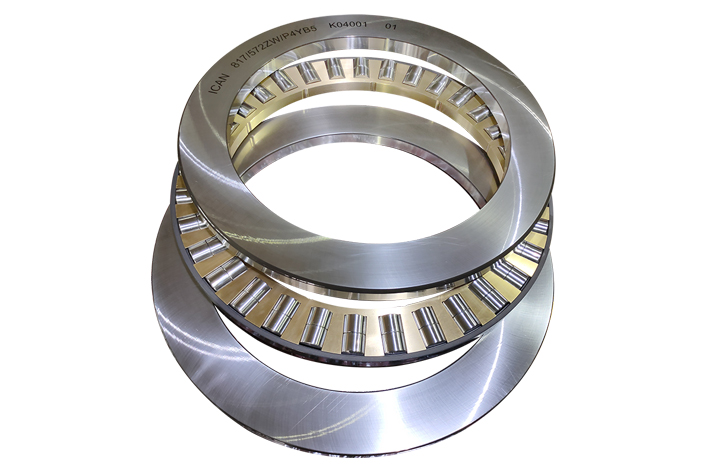

| Cylindrical Roller Thrust Bearing | Seller: DLAIAN GUANGYANG BEARING CO., LTD | Cylindrical Roller Thrust Bearing Cylindrical roller thrust bearings consist of rollers, cage co... | |

| Overflow Ball Mill | Seller: CITIC IC LUOYANG HEAVY MACHINERY CO., LTD | n recent years, with the continuous development of grinding technology, wet grinding has become t... | |

| Metallurgical Furnace | Seller: CITIC IC LUOYANG HEAVY MACHINERY CO., LTD | CIC main advantage in nonferrous metallurgical furnacelies in the manufacture of horizontal rotar... | |

| NTN 51236 Bearing,180x250x56,INA 51236 | Seller: BEARING POWER International Trading Co.,Ltd. | NTN 51236,Thrust Ball Bearing,180x250x56,INA 51236 | |

| INA 52305 Bearing,25x52x34,NTN 52305 | Seller: OKB INDUSTRIAL CO.,LTD. | INA 52305,Thrust Ball Bearing,25x52x34,NTN 52305 |