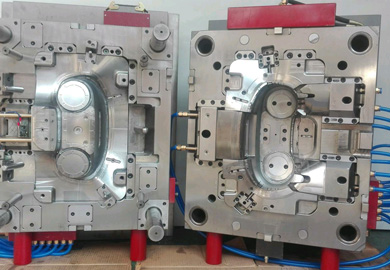

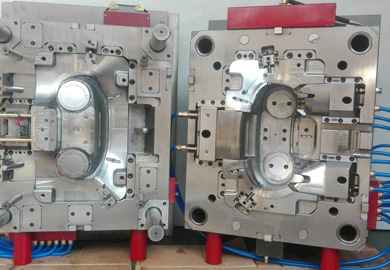

Insert Mould

Insert Mould

Insert moldingis an injection molding process used to encapsulate a component in a plastic part.

The insert injection moldingprocess can be divided into two basic steps. First, the component is loaded into the mold before the molding process. Second, it takes the shape of the part and locks the component into the plastic as molten plastic is injected into the mold.

Features of Insert Mould

Insert molding is the process of inserting a part into a mold prior to the injection molding process. Since the insert injection molding process is the same, different materials are fed into the mould so as to produce different mould products. The main features of using insert mould by GM-TECH, a reliable injection moulding manufacturer, include:

Improved strength

A strong and reliable attachment point for inserts

Cost-effective compared with other inserting processes

No significant mold changes required

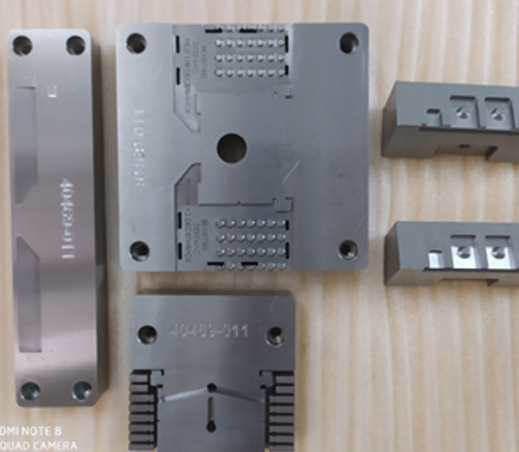

The Specification of Insert Mould

|

Part material |

ABS |

|

Cavity |

1 |

|

Mold accuracy |

+ / - 0.02 |

|

Mold steel |

H13 |

|

Moldbase steel |

|

|

Mold life |

100W |

|

Mold standard |

HASCO |

|

Mold structure |

3 slides |

|

Exporting country |

Germany |

|

Leadtime |

4 weeks |

|

Mold quality customer satisfaction |

|

|

FAI pass rate |

|

|

Project cooperation service customer satisfaction |

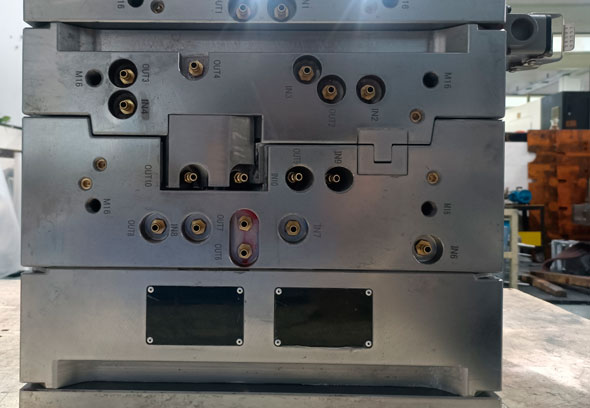

How does Insert Mould Work?

Insert molding is a powerful tool used to support the form and function of plastic injection molded parts. Insert molding refers to incorporating other parts, particularly metal parts, directly into the injection-molded product.

For instance, if there are metal inserts that we need to paste it to plastic. As an injection molding manufacturer, we need to place the metal inserts into the insert mold before injecting the plastic. The inserts will be surrounded by the plastic during the injection process, leaving the insert bonded firmly to the material after cooling and curing.

If you want to buy injection molded products, please contact us.

Send product request

Other supplier products

| Product Development | GM-TECH,a injection molding companies in china, has been manufacturing tools for injection molding of plastics for various industries for more than... | |

| Mould Component | GM-TECH,a injection molding companies in china, has been manufacturing tools for injection molding of plastics for various industries for more than... | |

| Injection Moulding Products | Injection Moulding Products GM-TECH has been manufacturing tools for injection molding of plastics for various industries for more than 10 years. ... | |

| Home Appliance Mould | Home appliance mold combines different types of molds such as gold stamping mould, plastic mould, and adsorption mould together. Therefore, househo... | |

| Mould Base | Mould Base After years of development, mold base production industry has been quite mature. Large plastic injection molding companiescan purcha... |

Same products

| Motorcycle Body and Frame Plastic Mold | Seller: Taizhou Huangyan Jingnan Moulding Co., Ltd. | As a key component mold professionally manufactured by Jingnan Mould, motorcycle body frame plast... | |

| For 2017 Audi A7 Rear Bumper Mould | Seller: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Mould Name Audi A7 Car Bumper Mould Material PP+EPDM(Contraction: 1, 5%) Bumper Size 1800*510*460... | |

| For Mercedes-Benz-C-206 Modified Bumper Mould | Seller: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Taizhou Huangyan Chenpeng Mold Co., Ltd. is a professionalwholesale Mercedes-Benz-C-206 Modified ... | |

| Front Bumper Lower Lip Mould For 2021 Honda CRV | Seller: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Introducing the for 2021 Honda CRV Front Bumper Lower Lip Mould: Elevate Your Driving Experienc... | |

| Bottle cap mold | Seller: Taizhou Huangyan Yongsheng Mould Co., Ltd. | Taizhou Yongsheng Mould Co., Ltd. can produce cap moulds ()within 64 cavities. The hot runner or ... |