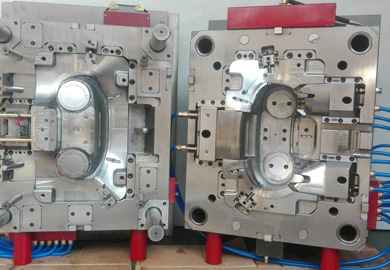

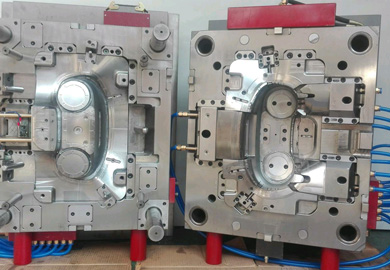

Home Appliance Mould

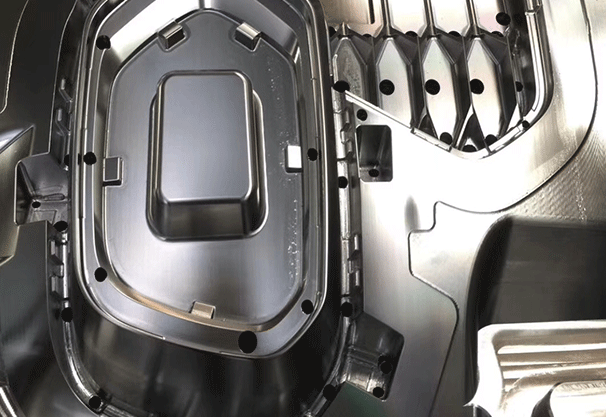

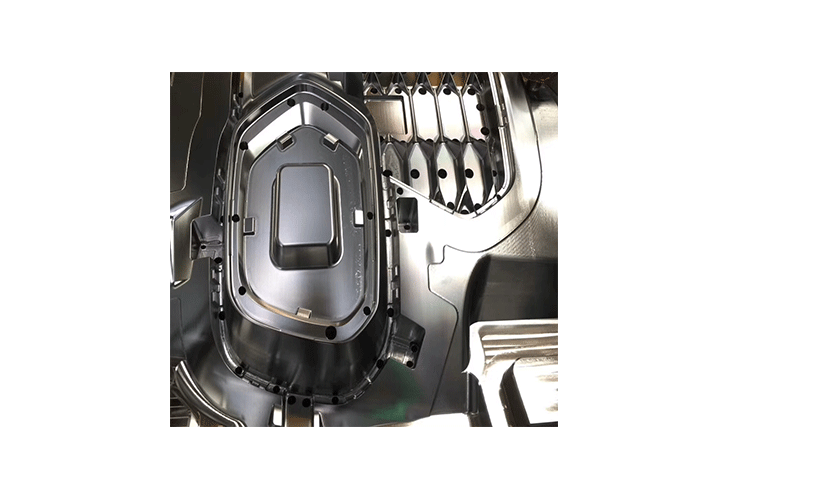

Home appliance mold combines different types of molds such as gold stamping mould, plastic mould, and adsorption mould together. Therefore, household

appliances are closely related to china home appliance mold.

As a leading home appliance china plastic injection molding company, GM-TECH makes sure all the products made by moulding meet the demanding requirements of our customers. We are devoted ourselves improving the service and home appliance mould quality continuously.

Features of Home Appliance Mould

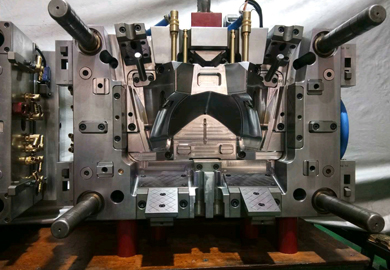

With the development of the home appliance industry, applications of home appliance mold are popular in the injection process such as fan mould, computer mould, air conditioner mould, refrigerator mould, and so on. So why are there wide applications of home appliance mold?

High precision and long service life

The home appliance mould adopts an inlaid or fully assembled structure, improving the high processing accuracy of plastic injection moulding parts.

Off-site design and off-site processing

The plastic home appliance mold process requires to meet customer needs and provide mass production by off-site design and off-site processing.

Short processing time

For injection home appliance mould parts, most of them are matched with other injection molding types, which can save processing time.

The Specification of Home Appliance Mould

|

High precision mould |

|

|

Part material |

PBT |

|

Cavity |

1L + 1R |

|

Mould accuracy |

+ / - 0.02 |

|

Mould steel |

|

|

Mouldbase steel |

|

|

Mould life |

100W |

|

Mould standard |

HASCO |

|

Mould structure |

4 slides |

|

Exporting country |

Russia |

|

Leadtime |

6 weeks |

|

Mould quality customer satisfaction |

96% |

|

FAI pass rate |

98% |

|

Project cooperation service customer satisfaction |

99% |

How does Home Appliance Mould Work?

Before we explore the working principle of home appliance mould, the first stage is to make a mould. Then the material is fed into a heated barrel and mixed using a helical-shaped screw.

Heating bands make the material melt. Next, the mixed materials, generally metal and plastic, are fed to the cavity of the home appliance mould to keep cooling. Finally, the shape of the home appliance mould is formed as we designed.

As a plastic mold technology inc, we will provide more high quality related products for sale, if you have needs, please contact us.

Send product request

Other supplier products

| Electronics Product Mould | Decades of accumulation of mould manufacturing technology have witnessed the popularity of electrical plastic molding products. The in mould ele... | |

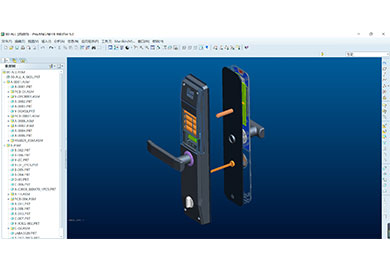

| Product Development | Our company is not engaged in product development, but we are willing to assist customers to design product appearance and product structure in cas... | |

| Die Casting Mould | Die Casting Mould Die casting mould is a method of casting liquid die forging. It is a process completed in a special die casting moulding machine... | |

| Mould Base | Mould Base After years of development, mold base production industry has been quite mature. Injection molding manufacturers can purchase custom... | |

| Automotive Part | We are a plastic injection manufacturer. In the spirit of a "one-stop-shop", our own tool workshop as well as an assembly and an international sale... |

Same products

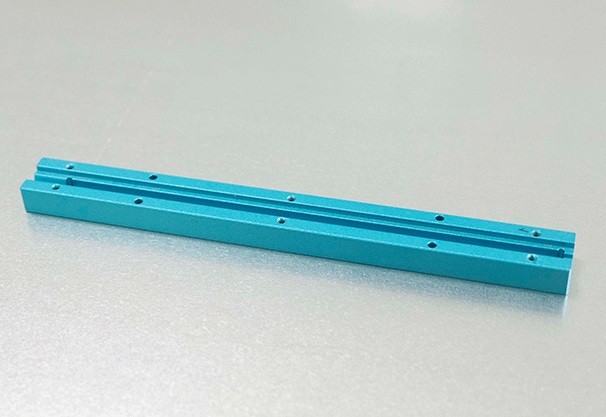

| Mold Components | Seller: Packson Mold Co.,Ltd | We provide custom made plastic parts-Sliders, inserts, lifters, blocks, ejector pins, and other m... | |

| Custom Metal Machining Parts | Seller: Packson Mold Co.,Ltd | Packson provides our customers a various CNC machining services to our customers, including milli... | |

| Clean Room Injection | Seller: Packson Mold Co.,Ltd | Packson - Medial Injection Moulding Cleanroom Expert Packson specializes in delivering top-notch ... | |

| Medical Plastic Injection Molding | Seller: Packson Mold Co.,Ltd | Packson - Medical Plastic Injection Molding Expert Packson sets itself apart from other medical i... | |

| CNC Metal Machining Parts | Seller: Packson Mold Co.,Ltd | Packson is a contract manufacturer specializing in CNC Milling, CNC Turning, CNC Drilling service... |