Family Mould

Family Mold Injection Molding 491138

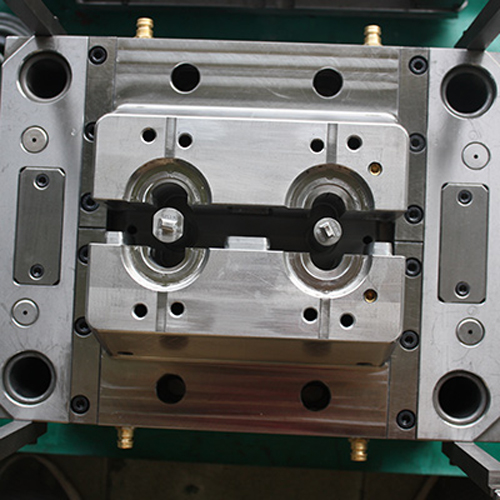

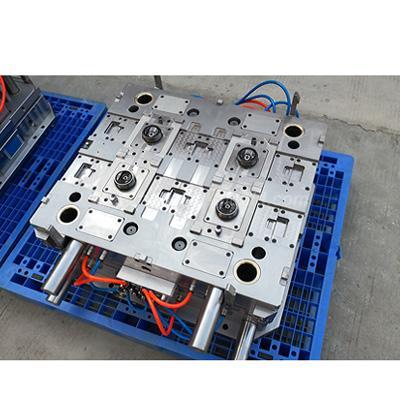

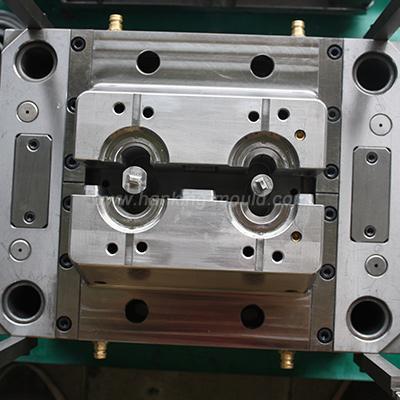

Mould Name: 1+1 Family Mould

Part Material: PA6 GF30

Product Size: 78*35.6mm

Product Description: Scharnier right & Left

Mould Cavity: 1 + 1 Cavity

Mould Size: 350*400*498MM

Mould Cavity Steel: 8407

Mould Injection System: 3-plate point gate

Mould Ejection System: ejector pin

Mould Cycle Time: 22s

Mould Life Cycle: 500,000

Lead Time: 35 working days

Mold export to: Europe

What is the family mold?

A mold that can only produce one product at a time is called a single-cavity injection mold. If an industrial mould is used to produce two or more plastic parts at a time, multi-cavity injection, if the parts are different, such a mold is called family mold.

The plastic parts produced by the single cavity mold have high precision, easy control of process parameters, simple mold structure, low mold manufacturing cost and short cycle time. However, the productivity of plastic molding is low, and the cost of plastic parts is high, which is suitable for large plastic parts, high precision requirements or small batches and trial production.

The plastic parts produced by the multi-cavity mold or family mold have low precision, it is difficult to control the process parameters, the mold structure is relatively complicated, the mold cost is high, and the cycle time is longer. However, productivity is higher, the cost of plastic parts is lower, and it is suitable for large quantities and long-term production of small-sized plastic parts.

The number of cavities is often determined by factors such as budget, clamping force, plastic part structure, and injection volume.

When designing a multi-cavity mold, one method is to determine the model of the injection molding machine, and then calculate the number of cavities according to the technical parameters of the injection molding machine and the technical requirements of the plastic parts; the other method is based on the requirements for production efficiency and the structure of the part require the number of cavities to be determined, and then choose the proper injection molding machine or check the existing injection molding machine.

We normally make the multi-cavity mold with 2 cavities, 4 cavities, 8 cavities, 16 cavities, 32 cavities, 48 cavities, etc. For family mold, we normally make at 1+1 cavities, 2+2 cavities, 4+4 cavities, 8+8 cavities, we can find the numbers are always double. Family mold help to molding different plastic parts in the same mould, this solution saves tooling and molding cost. For most family mold, the plastic part is in the same material & similar size, HanKing Mould will help customers to analyze the possibility to make the best economic plastic injection mould.

HanKing Mould Enginering Ltd. started the china custom plastic mold business in the year of 1996 as one of chinese plastic molding manufacturers in the line of plastic injection mold and precision molded plastics in Longgang, Shenzhen, China.

Other supplier products

|

|

Unscrewing Cap Mould 0440 |

2k MouldName: Unscrewing Cap Mould

Part Material: PP+TPE

Product Size:

Product Description:

Mould Cavity:

Mould Size: 750*810*700mm

Suitable... |

|

|

Medical Molding Parts |

Injection Parts Medical

HanKing has an experienced team focusing on making injection moulds and molded components for medical parts, medical instr... |

|

|

Family Mould |

As one of the most professional Chinese molding companies, we offer various plastic moldingwith high-quality, such as industrial mouldand so on.

F... |

|

|

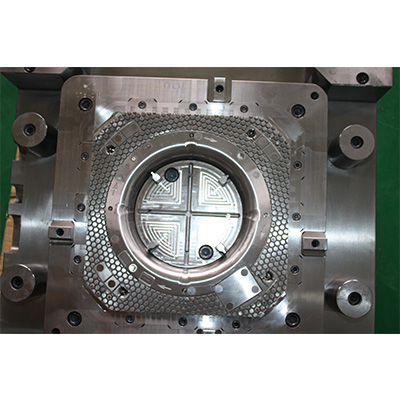

Plastic Mould for Air Guiding Fan |

With continuous developments and progresses, we have become theprofessional china plastic injection mould manufacturers, offering custom plastic in... |

|

|

Industrial Molding Parts |

Industrial hanking mould parts are referred to the plastic parts of industrial products, HanKing Mould Enginering Ltd.preferred to think of it as n... |

All supplier products

Same products