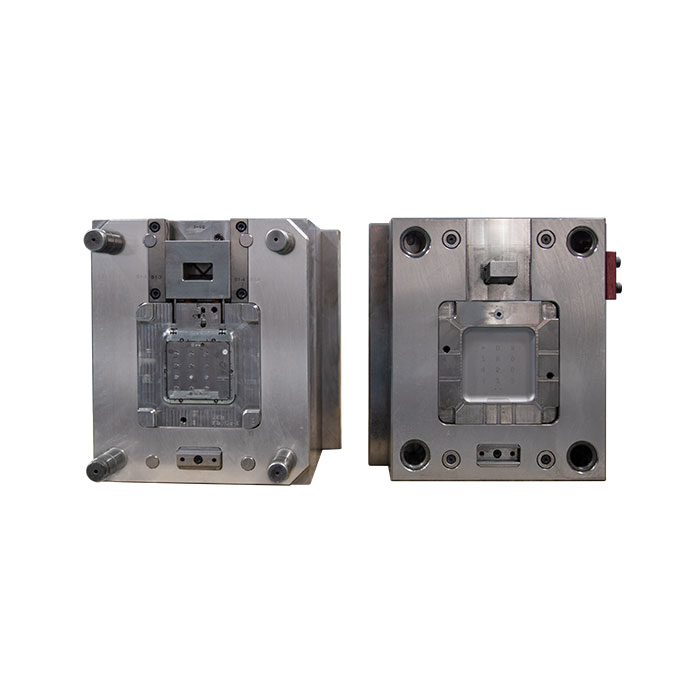

Gas & Water Assisted Injection Mold

Gas & Water Assisted Injection Mold

Since the thermal conductivity and heat capacity of water are much bigger than nitrogen, so the injection cycle of water-assisted is about 70% shorter than the injection cycle of gas assisted injection molding; The product wall thickness of water-assisted injection molding is more even than gas-assisted; The inner wall roughness of water assisted injection moldingis smoother than that gas-assisted injection molding.

WATER & GAS ASSISTED INJECTION MOLDED PRODUCTS

TV Frame Mold

Pushing the liquid plastic into the cavity and core side by high pressure during the injection process, and the gas pressure is maintained to form a hollow section inside the thick wall of the plastic part, the injection process is called gas-assisted injection molding.

Bike Frame Mold for Kids

During plastic molding processing, gas-assisted injection molding is abbreviated as GAIM, which is a relatively new molding processing technology, this technology is comprehensively developed on the basis of the design and manufacture of traditional injection molding molds and blow molding molds, and entered the practical stage in the 1990s, gas-assisted injection molding has huge technical application advantages and can produce significant economic benefits.

Car Ceiling Handle Injection Mould

When plastic injection molding, the melt is under the injection pressure and enters the mold cavity, on the same section, the flow rate of each gate is different, the fastest in the middle, the closer to the cavity wall, the slower the flow rate, and it contacts the cavity wall, the speed of the first layer is zero.

Gas Assisted & Water Assisted Injection Molding Differences

- injection mold chinacost is much higher than that of gas injection mold.

Gas-Assisted Injection Molding Process

Gas-assisted injection molding is roughly divided into 4 stages: plastic injection, gas injection, pressure-holding cooling, and gas discharge.

Gas-assisted injection molding classification

- insert injection molding: under-material injection molding is also called short shot, inject part of the plastic melt (usually 50%-90% of the cavity volume) into the mold cavity first, and then inject gas to use push the melt to complete mold filling and pressure holding by gas, the gas injection time and gas pressure are very important to the product quality, to inject the gas too early or pressure is too high will cause the gas to penetrate the melt front, otherwise it will lead to incomplete feeding and surface defects. In this type of gas injection moulding process, when the gas pressure is too high and the gas is injected too early, gas penetration cannot be avoided, if the gas pressure is too low and the gas is injected too late, the gas will not enter the plastic and will not be able to promote the flow of the melt front. Increasing the initial air pressure can avoid stagnation of the forward melt, and there will be no traces on the surface of the product, the under-material injection process is suitable for the molding of rod-shaped products or plate-shaped products with partial walls thickness.

As one of gas injection moulding manufacturers, we will do our best to meet all the needs of customers.

Send product request

Other supplier products

| Auto Parts Mould | Auto Parts Mould Automotive Parts Moldfeatures: More kinds of molded automotive parts, please visit our website. As one of injection m... | |

| Plastic Household Mould | Plastic Household Mould The smart switches and smart sockets of the smart home systems have the same specifications as normal power switches and... | |

| 2K Mold | 2KMolds The rotary mold is composed of two-cavity and core sides, the two core sides are the same, only the cavity sides is different which the ... | |

| Overmolding & 2k Molding | Overmolding& 2k Molding The same type of material of different colors is usually used for two-color injection molding(or 2k injection moldin... | |

| Insert Mold | Insert Mold USM molds focus on structural parts injection molds, water-assisted Gas-assisted injection molds, small parts plastic molds, precision... |

Same products

| Motorcycle Body and Frame Plastic Mold | Seller: Taizhou Huangyan Jingnan Moulding Co., Ltd. | As a key component mold professionally manufactured by Jingnan Mould, motorcycle body frame plast... | |

| For 2017 Audi A7 Rear Bumper Mould | Seller: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Mould Name Audi A7 Car Bumper Mould Material PP+EPDM(Contraction: 1, 5%) Bumper Size 1800*510*460... | |

| For Mercedes-Benz-C-206 Modified Bumper Mould | Seller: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Taizhou Huangyan Chenpeng Mold Co., Ltd. is a professionalwholesale Mercedes-Benz-C-206 Modified ... | |

| Front Bumper Lower Lip Mould For 2021 Honda CRV | Seller: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Introducing the for 2021 Honda CRV Front Bumper Lower Lip Mould: Elevate Your Driving Experienc... | |

| Bottle cap mold | Seller: Taizhou Huangyan Yongsheng Mould Co., Ltd. | Taizhou Yongsheng Mould Co., Ltd. can produce cap moulds ()within 64 cavities. The hot runner or ... |