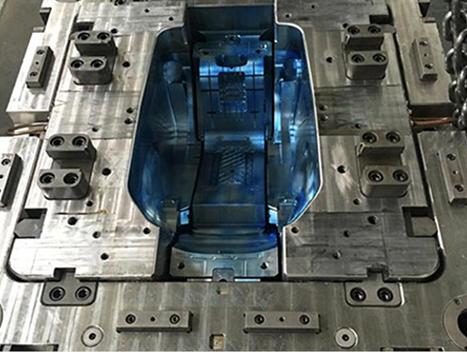

Plastic Enclosure Mold For Electronic Device

In a Lego game, you will hold the laser, sit on the device, and shoot various targets. Since this game is mainly to meet the gaming experience of LEGO fans at a young age, the plastic product shell is required not only to be polished well, but also to be wear-resistant. In addition, because it is a laser electronic housing, it needs to be assembled with electronic components, so the precision requirements for plastic products are relatively high. Finally Green Vitality provide perfect plastic enclosure moldafter first trial.

Plastic Injection Mold Steel Requirements For Electronic Enclosure Part

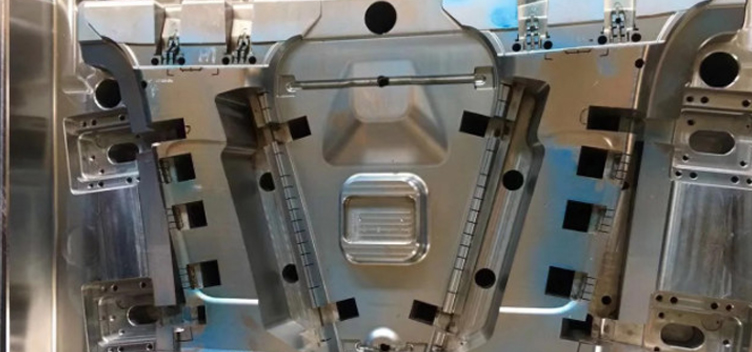

Good polishing performance. Electronic enclosure plastic part injection mold materials usually require good gloss and surface condition. Therefore, the roughness of the cavity surface is required to below. In this way, the surface of the cavity must be surface processed, such as polishing, grinding, etc. Therefore, the selected plastic injection mold steel should not contain rough impurities and pores.

Less affected by heat treatment. In order to improve the hardness and wear resistance, the electronic enclosure plastic injection mold is generally heat-treated, but this treatment should make the size change small. Therefore, it is best to use pre-hardened steel that can be machined.

Good wear resistance. The gloss and accuracy of the surface of the electronic enclosure injection mold material are directly related to the wear resistance of the surface of the injection mold cavity, especially when glass fiber, inorganic fillers, and certain pigments are added to some plastics. Together with the plastic melt, it flows at a high speed in the runner and mold cavity, and the friction on the surface of the cavity is great. If the material is not wear-resistant, it will wear quickly.

Plastic Injection Mold Steel Requirements For Electronic Enclosure Part

Good polishing performance. Electronic injection molded enclosuresmaterials usually require good gloss and surface condition. Therefore, the roughness of the cavity surface is required to below. In this way, the surface of the cavity must be surface processed, such as polishing, grinding, etc. Therefore, the selected plastic injection mold steel should not contain rough impurities and pores.

Less affected by heat treatment. In order to improve the hardness and wear resistance, the electronic enclosure plastic injection mold is generally heat-treated, but this treatment should make the size change small. Therefore, it is best to use pre-hardened steel that can be machined.

Good wear resistance. The gloss and accuracy of the surface of the electronic enclosure injection mold material are directly related to the wear resistance of the surface of the injection mold cavity, especially when glass fiber, inorganic fillers, and certain pigments are added to some plastics. Together with the plastic melt, it flows at a high speed in the runner and mold cavity, and the friction on the surface of the cavity is great. If the material is not wear-resistant, it will wear quickly.

Features For Plastic Electronic Enclosure Part

The enclosure of electronic products is one of the commonly used plastic products. People not only have requirements for the function of the finished product but also attach great importance to the material of the shell. The high-quality electronic plastic shell not only has a good appearance but also can effectively extend the service life of the product. So, what are the characteristics of electronic enclosures?

At present, the plastic shells on the market have various styles and complete sizes, but their materials are very different. Most of the electronic enclosures are made of high-quality flame-retardant and fire-retardant ABS materials.

Flame-retardant and fire-retardant ABS materials have excellent impact resistance, heat resistance, low-temperature resistance, chemical resistance, and electrical properties. It also has the characteristics of easy processing, stable product dimensions, and good surface gloss. It is easy to paint, color, secondary processing such as metal spraying, electroplating, welding, hot pressing, and bonding can also be performed on the surface.

In the production of ABS plastic and then adding fire retardant, the electronics enclosure produced not only has the advantages of ABS material but also makes the product have fire resistance.

Green Vitality Industry is a professional injection molding supplierin various industries since 1993. We provide car bumper injection moulding, injection mouldingand etc. Want to know more, contact us.

Send product request

Other supplier products

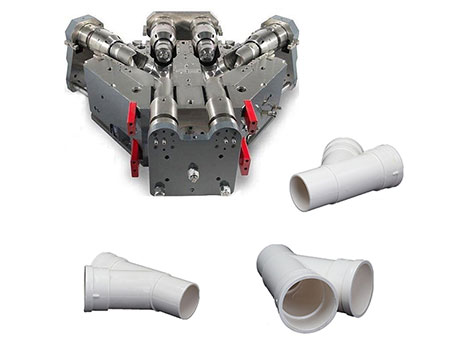

| Industrial Plastic Injection Mold | Industrial Plastic Injection Mold The injection molding part is replacing metal products in many fields of industrial applications to meet the... | |

| Plastic Food Container Mould | Plastic meal boxes mainly used for packing foods, so it need to be heat resistant and non-toxic,and could meet the requirements of environmental pr... | |

| Auto Part Mold | With the vigorous development of the automotive industry, plastic auto part mold is also developing rapidly. 90% of auto parts are produced by inje... | |

| Electronics Mold | Consumer electronics is very popular in our daily life. It consists of many different plastic parts, pcb boards, wires, battery and some metal part... | |

| Injection Mold & Molding Parts Solution | Green Vitality Industry is a full-service mold manufacturer specializing in plastic injection mold design & engineering support, injection mold... |

Same products

| Motorcycle Body and Frame Plastic Mold | Seller: Taizhou Huangyan Jingnan Moulding Co., Ltd. | As a key component mold professionally manufactured by Jingnan Mould, motorcycle body frame plast... | |

| For 2017 Audi A7 Rear Bumper Mould | Seller: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Mould Name Audi A7 Car Bumper Mould Material PP+EPDM(Contraction: 1, 5%) Bumper Size 1800*510*460... | |

| For Mercedes-Benz-C-206 Modified Bumper Mould | Seller: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Taizhou Huangyan Chenpeng Mold Co., Ltd. is a professionalwholesale Mercedes-Benz-C-206 Modified ... | |

| Front Bumper Lower Lip Mould For 2021 Honda CRV | Seller: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Introducing the for 2021 Honda CRV Front Bumper Lower Lip Mould: Elevate Your Driving Experienc... | |

| Bottle cap mold | Seller: Taizhou Huangyan Yongsheng Mould Co., Ltd. | Taizhou Yongsheng Mould Co., Ltd. can produce cap moulds ()within 64 cavities. The hot runner or ... |