Injection Molding Service

As a china abs molding supplier, Keyplast has leading advantages in custom plastic molding industry, with rapid quotation, professional design, efficient processing, regular feedback, strict quality-control and automatic packaging. For prototyping, we provide professional suggestions for your drawings; for manufacturing, provide specified material testing until the most suitable material confirmed; for production, provide small-batch, customized services, and one-stop butler solutions.

Our Injection Molding Service

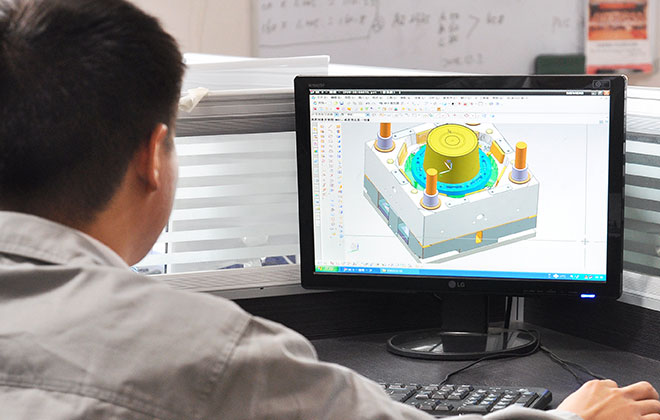

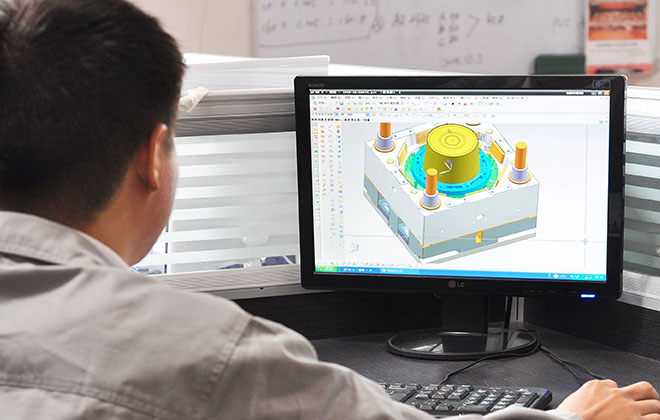

Injection Mold Design Engineering

Injection Mould Design Engineering is a procedure at the first stage of injection molding process, which develops the injection mold designs to improve the effectiveness and efficiency in injection molding. Plastic mold design technical team of R&D and engineers of Keyplast is diligent for every project from our clients. As a leading plastic injection molding service factoryand plastic injection molding service manufacturerin China, Keyplast could assist our clients to make 2D/3D designs per the samples or concepts and bring their ideas into reality. If any defects, our team will offer professional suggestions and take rapid modifications for every project.

Plastic Injection Mould Tooling

Plastic molds are tools that are matched with plastic mold making machines in the plastic processing industry to give plastic products a complete configuration and precise dimensions. Due to the wide variety of plastics and processing methods, and the complex and simple structures of plastic injection mold making machines and plastic products, the types and structures of plastic molds are also diverse.

Custom Injection MoldingSurface Finish

Do not use the finest whetstone, sandpaper, or abrasive polishing paste at the beginning of mold polishing, as you can't throw away the rough lines. The living surface polished in that way looks very shiny, but when you take a side view, the rough lines appear. Therefore, it is necessary to polish from coarse whetstone, sandpaper or abrasive polishing paste, then change to finer whetstone, sandpaper or abrasive polishing paste for polishing, and finally polish with the finest abrasive polishing paste. This seems to be cumbersome and there are many processes. In fact, it is not slow. One process after another, the rough processing lines in the front are polished off, and then the following injection molding process step is carried out without rework, and the injection molding surface finish can meet the requirements with one step.

Send product request

Other supplier products

| Injection Molding Service | As a plastic injection molding service factoryand plastic injection molding service manufacturer, Keyplast has leading advantages in custom plastic... | |

| Insert Molding | Insert molding serviceis one category of injection molding that allows preformed parts or components, usually metal inserts, to be inserted into th... | |

| Over Molding | Over moldingof keyplast is a special plastic molding process. Overmolding custom injection moldingis similar to the two-color molding or two-shot m... | |

| Medical Injection Molding | Keyplast has efficient team with many years' experience of injection moulding, while medical industry is one of our mainly focused industries. With... | |

| Injection Mold Design Engineering | Injection Mold Design Engineering Injection mold engineeringis a procedure at the first stage of injection molding process, which develops the inj... |

Same products

| Motorcycle Body and Frame Plastic Mold | Seller: Taizhou Huangyan Jingnan Moulding Co., Ltd. | As a key component mold professionally manufactured by Jingnan Mould, motorcycle body frame plast... | |

| For 2017 Audi A7 Rear Bumper Mould | Seller: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Mould Name Audi A7 Car Bumper Mould Material PP+EPDM(Contraction: 1, 5%) Bumper Size 1800*510*460... | |

| For Mercedes-Benz-C-206 Modified Bumper Mould | Seller: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Taizhou Huangyan Chenpeng Mold Co., Ltd. is a professionalwholesale Mercedes-Benz-C-206 Modified ... | |

| Front Bumper Lower Lip Mould For 2021 Honda CRV | Seller: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Introducing the for 2021 Honda CRV Front Bumper Lower Lip Mould: Elevate Your Driving Experienc... | |

| Bottle cap mold | Seller: Taizhou Huangyan Yongsheng Mould Co., Ltd. | Taizhou Yongsheng Mould Co., Ltd. can produce cap moulds ()within 64 cavities. The hot runner or ... |