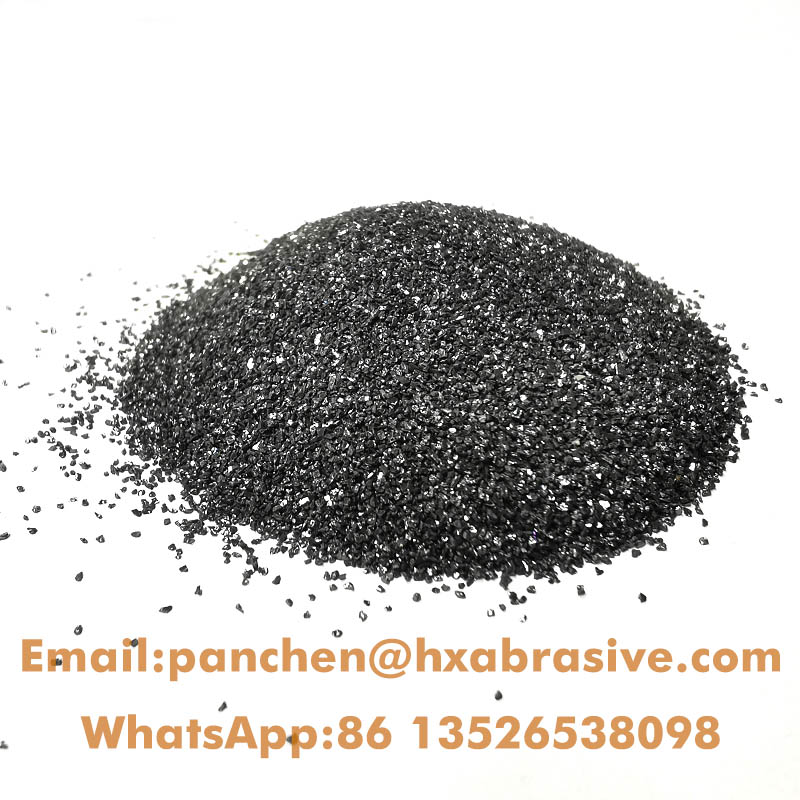

Green silicon carbide F150

Green silicon carbide grit

Green silicon carbide grit is a very hard abrasive material . The hardness of itonly ranks after diamond and B4C, and it is harder than black silicon carbide. So it is suitable to grinding large range of hard material such as titanium alloy, marble, carbide alloy, optical glasses, ceramics, etc.

Green Silicon Carbide is produced at high temperature in an electric resistance type furnace with quarts sand and petroleum coke. The SiC purity of green silicon carbide is up to 99%min. It is an artificial brittle SiC with high thermal conductivity and high strength which get no decrease in 1000 centigrade.

Typical physical properties of Green silicon carbide grit

|

Mohs Hardness: |

|

|

Vickers Hardness: |

3100-3400kg/mm2 |

|

Specific Gravity: |

|

|

Bulk density(LPD): |

|

|

Color: |

Green |

|

Particle shape: |

Hexagonal |

|

Melting Point: |

Dissociated at about 2600 centigrade |

|

Maximum service temperature: |

1900 centigrade |

|

Friability |

Friable |

|

Thermal conductivity |

|

|

Thermal expansion coefficient |

7-9 x10-6 /℃(0-1600°C) |

Chemical analysis of Green silicon carbide grit

|

TYPICAL CHEMICAL ANALYSIS |

||

|

Chemical Content |

F20-F220 |

F230-F2000 |

|

SiC |

Min 99% |

Min 98.5% |

|

SiO2 |

Max 0.50% |

Max 0.70% |

|

F,Si |

Max 0.20% |

Max 0.40% |

|

Fe2O3 |

Max 0.10% |

Max 0.15% |

|

Max 0.20% |

Max 0.30% |

|

|

Max 0.05% |

Max 0.09% |

|

Product Feature of Green silicon carbide grit

- Extremely high hardness (Mohs 9.5, Vickers 3100-3400kg/mm2) with high wear-resistance ability. The hardness of SiC decrease with the increasing of temperature. But still, even at the temperature of 1200°C, the hardness of green SiC is about twice that of fused alumina’s.

- Excellent chemical resistance and oxidation resistance. When heated at high temperatures, silicon carbide only oxidizes on the surface, forming a silicon dioxide film. The film can protect the silicon carbide material from oxidation.As a result, even in 1600°C ,green SiC can maintain stability to most strong acids and alkalis.

- High Toughness.The toughness of silicon carbide abrasive refers to the difficulty of breaking under the action of external force. Taking F46 grit as an example, the toughness of carborundum tested by static pressure method is about 68-78%.Comparing with fused alumina, the mechanical strength of silicon carbide is higher. F120 for example, the compressive strength of silicon carbide is 186KN/cm2, and the compressive strength of corundum abrasive is 100KN/cm2.

- Excellent thermal shock resistance with low thermal expansion coefficient. At a temperature of 25-1400°C, the average thermal expansion coefficient of silicon carbide is 4.4x10-6/°C, while the thermal expansion coefficient of fused alumina is 7-8x10-6/°C.

- High temperature resistance; high temperature strength. The melting point of green silicon carbide is 2600 °C, and the maximum operating temperature can reach 1900 °C. Applying silicon carbide to the inner wall of the engine can increase the life of the engine.

- High purity. The green silicon carbide grain from us is milling from A grade green SiC block. Then sieve to high consistency particles.

Applications of Green silicon carbide grit

- Precision polishing for hard optical glass such as camera lens.

- Abrasive blasting on hard metal materials such as titanium alloy, carbide alloy, etc.

- Polishing and grinding quartz glass.

- Grinding hard stone, marbles, granite, etc.

- Polishing PZT/Piezoelectric ceramic.

- Blasting copper and copper alloy.

- Surface treatment on diamond tools.

- Wire sawing.

- Polishing jewelry such as diamond and cinnabar.

- Grinding other thin brittle material precise component.

Send product request

Other supplier products

| Silicon carbide 53C 54C F030 F036 for marble blasting | Black Silicon carbide Grain is an extremely hard and 99% SiC carborundum grit. As an abrasive material, it can work well for abrasive blasting, sur... | |

| Shot blasting media Ceramic beads B100 B125 | Shot blasting media Ceramic beads B100 B125 The main component of ceramic shot is zirconia, which is mainly used for surface treatment such as s... | |

| B4C powder F230 F240 95% boron carbide raw material | B4C powder F230 F240 95% boron carbide raw material neutron shielding additive B4C boron carbide powder,also known as B4C is produced from high te... | |

| Green silicon carbide SiC powder 63C F320 F360 | Green silicon carbide SiC powder 63C F320 F360 Green silicon carbide powder is a very hard abrasive material with uniform particle size distribu... | |

| Casting ceramic sand AFS30 AFS35 AFS40 AFS45 AFS50 | Casting ceramic sand AFS30 AFS35 AFS40 AFS45 AFS50 Ceramic Foundry Sand is a corundum based casting sand. It is produced from fusing bauxite mater... |

Same products

| Dresser, 0.4 Carat Single Point Grinding Wheel Tapered Point Tool for Dressing and Grinding Bench, Item surface, Cylindrical Internal Grinding | Seller: 青岛晟鑫杰金刚石工具有限公司 | ||

| Aluminum Oxide Fiber Disc | Seller: CHANGZHOU RMN ABRASIVES CO., LTD | Aluminum Oxide Fiber Disc It is strong and has durable, long sanding life, high sanding performa... | |

| AJ26M Abrasive Belts for Metal | Seller: CHANGZHOU RMN ABRASIVES CO., LTD | AJ26M Abrasive Belts for Metal RMC AJ26M abrasive belts for metal backing is Jwt flexible and hi... | |

| AJ25 Aluminium Oxide Abrasive Belts | Seller: CHANGZHOU RMN ABRASIVES CO., LTD | AJ25 Aluminium Oxide Abrasive Belts The backing cloth make anti-slip treatment with high strengt... | |

| AF37M Green Abrasive Film | Seller: CHANGZHOU RMN ABRASIVES CO., LTD | RMC AF37M green abrasive microfinishing filmcan be used as Velcro and PSA disc, and also suitable... |