The structure of the melt pump design

IKV(Shanghai)Industry Co.,Ltd(Tel: Website: ) is the leading manufacturer for melt pump, gear pump, metering pump, screen changer, die head, feed block and extruder lines in China. Our product widely used in plastic and rubber industry. Being a professional manufacturer, we are not only supply the best product. We also provide technical solutions for customs. We have been accumulating adequate experience on the application-specific technique.We have excellent team of engineers and quality control system to deliver quality value product and providing most important after sales service.

The structure of the melt pump design

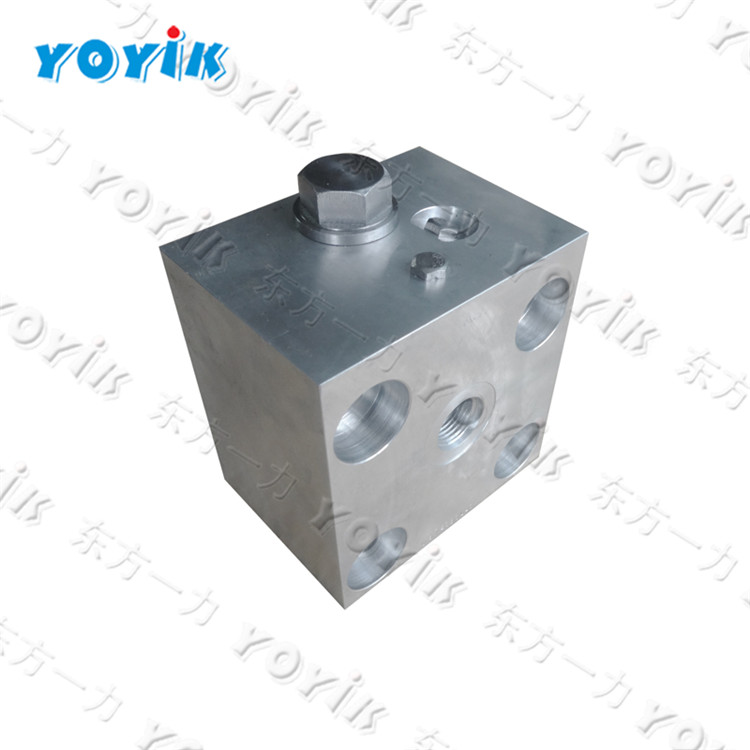

Polymer extrusion processing and the application of the melt pump are usually combined structure, three parts by two mutually meshing of the driving gear and driven gear, pump body, pump cover and pump body on both sides of external heating cooling device.Within the melt pump driving gear by the long axis directly connected to the driving gear, driven gear under the drive of driving gear rotate in the direction of the conveyor, through both the rotation of the polymer melt conveying to the nose.

Gear design in polymer processing of the application of the melt pump gear has three types, straight teeth and helical teeth and herringbone gear.Straight teeth gear manufacture simple, low cost, and the intensity of a big, under the condition of high output pressure has a larger effective volume of output.Helical gear self-cleaning capability is strong, the material stay in the melt pump for a short time.The most important of all, the fluctuating pressure of the output of the helical gear is lower than straight tooth, straight teeth of pulse pressure is 1% - 1.5% of the output pressure, and helical pulse pressure is 0.5% - 1% of the output pressure.So for large size melt pump pressure pulse is obvious, with a helical gear pump is good.For discharging speed tooth/min at 200-400 range of small, melt pump with straight tooth gear is completely possible.When the melt into the converter and mold, small pulse pressure basically have been offset.Helical gear fault is a produce axial load, sometimes in order to reduce the axial load in the spiral Angle of helical gear is small, the advantages of both the herringbone helical can offset the axial load, but the herringbone gear shear force is bigger, is easy to make the material thermal degradation, so should not be used for the processing and heat sensitive materials.

Other supplier products

|

|

The structure of the melt pump design |

IKV(Shanghai)Industry Co.,Ltd(Tel: Website: ) is the leading manufacturer for melt pump, gear pump, metering pump, screen changer, die head, feed ... |

|

|

Melt metering pump heating mode is what |

IKV(Shanghai)Industry Co.,Ltd(Tel: Website: ) is the leading manufacturer for melt pump, gear pump, metering pump, screen changer, die head, feed ... |

|

|

Plastic Plate Die |

IKV(Shanghai)Industry Co.,Ltd is the leading manufacturer for melt pump, gear pump, metering pump, screen changer, die head, feed block and extrude... |

|

|

Continuous Mesh Filter Screen Changer |

Continuous Mesh Filter Screen Changer is fully automatic, which mainly controls the screen changing melt pressure or time. You can set the screen m... |

|

|

Double Column Big Size Screen Changer |

Features and advantages: 1,large filtering area, reduce changing times. 2, improve the network of time interval,can fully eliminate the material ... |

All supplier products

Same products