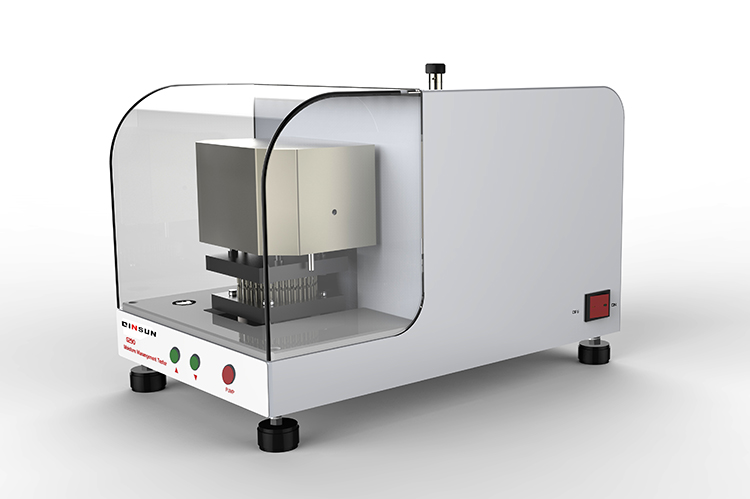

Slip Resistance Tester

Slips and trips are the most common cause of major injuries at work and can happen almost anywhere-broken bones and other serious injuries frequently result from major slips and slipping can also be the initial cause for a range of other types of accident, such as fall from height. Significant numbers of slip accidents also occur in the home and during sports and recreation.

Footwear has to be fit-for-purpose, which means that it should be fit for all its intended purposes, including any indicated by the retailer, and provide a reasonable and appropriate degree of safety. Legislation and regulations help to define what this means. Where there are specific hazards to be managed, it may mean providing slip-resistant safety floors and/or slip-resistant footwear.

Footwear non-slip performance directly affects the safety and comfort of shoes, poor slip, means that there is a potential risk to personal safety, especially easily lead to crash in the wet, light, slippery ground for children and the elderly and other vulnerable groups. Many slippage and falls are very serious. Slip and slippage occur only for a moment, but the consequences may be accompanied by life. At present, slipping has been considered to be one of the main causes of accidents in the workplace, public places and home environment.

The unique design of the slip resistance tester can measure the slip resistance of the shoes with the standard ground, and measure the slip resistance of the floor material with the standard sole material. The fast and accurate control and data acquisition system ensure the force and speed requirements in the test process with the intuitive and convenient visual display results.

Standards

1. ASTM F2913standard test method for measuring the coefficient of friction for evaluation of slip performance of footwear and test surfaces/flooring using a whole shoe tester

2. BS EN 13287Personal protective equipment. Footwear. Test method for slip resistance

3. GB/T 28287Foot protection- Test method for footwear slip resistance

4. EN ISO 20344Personal protective equipment - Test methods for footwear

5. Satra TM144A New Method of Non - slip Test for Footwear

6. CEN/TC 161 WG3

Features

Automatically calculate the friction coefficient.

Multi-Path output.

The software has Windows high compatibility features.

Technical Parameters

Footwear has to be fit-for-purpose, which means that it should be fit for all its intended purposes, including any indicated by the retailer, and provide a reasonable and appropriate degree of safety. Legislation and regulations help to define what this means. Where there are specific hazards to be managed, it may mean providing slip-resistant safety floors and/or slip-resistant footwear.

Footwear non-slip performance directly affects the safety and comfort of shoes, poor slip, means that there is a potential risk to personal safety, especially easily lead to crash in the wet, light, slippery ground for children and the elderly and other vulnerable groups. Many slippage and falls are very serious. Slip and slippage occur only for a moment, but the consequences may be accompanied by life. At present, slipping has been considered to be one of the main causes of accidents in the workplace, public places and home environment.

The unique design of the slip resistance tester can measure the slip resistance of the shoes with the standard ground, and measure the slip resistance of the floor material with the standard sole material. The fast and accurate control and data acquisition system ensure the force and speed requirements in the test process with the intuitive and convenient visual display results.

Standards

1. ASTM F2913standard test method for measuring the coefficient of friction for evaluation of slip performance of footwear and test surfaces/flooring using a whole shoe tester

2. BS EN 13287Personal protective equipment. Footwear. Test method for slip resistance

3. GB/T 28287Foot protection- Test method for footwear slip resistance

4. EN ISO 20344Personal protective equipment - Test methods for footwear

5. Satra TM144A New Method of Non - slip Test for Footwear

6. CEN/TC 161 WG3

Features

Fast fasten device can quickly install the sample and lock with the host. It simplify the sample installation process to avoid the differences test results and improve test experience and test results accuracy.

Real - time load acquisition system.

Real - time load acquisition system.

Support component and regulator indicator, real-time display test status.

Pneumatic lifting control system to meet the requirements of different thickness test specimens.

Irregular surface support tools to adapt the surface of the test material, providing the uniform load and the pilot force.

Irregular surface support tools to adapt the surface of the test material, providing the uniform load and the pilot force.

Adjustable test inclination to meet different test requirements.

Dial-type adjustment, convenient and quick. You can observe the tilt angle changes and adjust promptly in the test process.

Real-time analysis management software provides the visual display of maximum friction, minimum friction, the average friction.Dial-type adjustment, convenient and quick. You can observe the tilt angle changes and adjust promptly in the test process.

Automatically calculate the friction coefficient.

Multi-Path output.

The software has Windows high compatibility features.

Technical Parameters

| Items | Parameters |

| Angle of inclination | -40°- 40°(adjustable) |

| Load | Up to 600N |

| Torque speed | Up to 50N within 0.2s |

| Testing speed | 0.3m/s, other speed can be set |

| Time accuracy | 0.1s |

| Time display accuracy | 0.01s |

| Measurement parameters | Maximum friction, minimum friction, average friction, coefficient of friction |

| Power | 220V, 50Hz |

| Dimension | 1200 mm(W)×700mm(L)×1050mm (H) |

| Weight | 75kg |

Loading