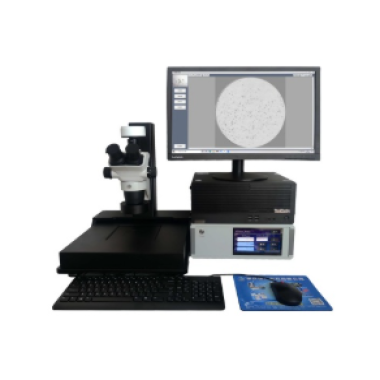

Strength Tester for Lead - end of Photovoltaic Modules

The Strength Tester for Lead-End of Photovoltaic Modules is designed to evaluate the mechanical integrity and tensile strength of PV module connectors and leads. It ensures the durability and reliability of electrical connections under standardized loading conditions, supporting quality control, R&D, and compliance verification for photovoltaic modules.

Application

(1) Mechanical testing of MC4, H4, and custom PV module connectors

(2) Lead-end tensile strength verification for 72-cell and large-format modules

(3) Evaluation of junction box durability under repeated thermal cycling

(4) R&D testing for module design optimization

(5) QC inspection in manufacturing lines to ensure IEC 61215-2 compliance

(6) Failure analysis for IV curve correlation and connector degradation studies

Standards

(1) IEC 61215-2:2016 – Test Requirements for Electrical and Mechanical Components of Terrestrial PV Modules

(2) CE Certification (Conformité Européenne)

Features

(1) Motorized Tensile Stage: Adjustable 0–500 mm/min with real-time force-displacement graphing

(2) Dynamic Force Feedback: 0.1 N resolution load cell with peak force memory

(3) Self-Calibrating System: Auto-linearity and tare checks before each test

(4) Quick-Change Fixtures: Compatible with MC4, H4, and custom PV connectors

(5) User-Centric Interface: 7” touchscreen HMI with preloaded IEC 61215-2 test sequences

(6) Durable Construction: Rust-resistant 304 stainless steel frame with epoxy coating

(7) Automated Testing: Programmable load profiles simulating long-term mechanical stress

(8) Safety Systems: Emergency shutoff and overload protection at 5 kN

Parameters

| Parameter | Specification |

|---|---|

| Test Area | 2,000 mm × 1,000 mm (customizable) |

| Force Range | 0–5,000 N (5 kN capacity) |

| Force Resolution | 0.1 N (10 gf) |

| Speed Accuracy | ±1% of setpoint |

| Power Supply | 220V AC, 50/60Hz (single-phase) |

| Dimensions | 2,200 mm (W) × 1,200 mm (D) × 1,800 mm (H) |

| Weight | 250 kg (net) |

Accessories

(1) Testing Kit: 10x PV connector fixtures (MC4/H4 compatible), 5x calibration grade load cells (10 N–5,000 N)

(2) Software Suite: License key for TensileTest Pro (Windows/Linux), 1-year free access to cloud-based fatigue analysis tools

(3) Calibration & Safety: NIST-traceable force gauge, insulated gloves (Class 0, 3 pairs)

(4) Maintenance Kit: Spare drive belts and bearings, machine cleaning solution (non-corrosive)

(5) Documentation: Multilingual quick-start guide (printed + digital), IEC/UL/ISO compliance certificates

Test Procedures

(1) Mount PV module leads or connectors into quick-change fixtures.

(2) Select desired force profile and speed via touchscreen interface.

(3) Begin tensile test while monitoring real-time force-displacement data.

(4) Automatically record peak force and failure events.

(5) Export results and generate test report for QC or R&D evaluation.

Maintenance Information

(1) Inspect load cells, clamps, and drive belts regularly for wear or damage.

(2) Clean fixtures and frame surfaces with non-corrosive cleaning solutions.

(3) Verify calibration of force measurement system periodically.

(4) Lubricate moving parts according to scheduled maintenance.

(5) Store in a dry environment to maintain precision and prolong service life.

Send product request

Other supplier products

| Rubber Mooney Viscosity meter | Test principle: The Mooney viscometer is used to measure the viscosity of rubber under specific conditions. In the test, the rubber sample was loa... | |

| Cleanliness Analysis System | Production: The cleanliness analysis system fully complies with the requirements of standards such as VDA19.1 - 2015. ISO16232. ISO4406. ISO4407. ... | |

| Safety Helmet Chin-strap Strength Tester | Standard GB/T 2812-2006: Safety Helmets GB/T 2811-2019: Head Protection – Vocabulary and Test Methods Equivalent Compliance: ISO/EN 397 (I... | |

| UV Exposure Test Machine丨UV Exposure Tester | Features and Benefits 1.Accelerated aging testing can simulate the aging effect of materials in natural environments for years within tens or hu... | |

| Sliding bearing PV friction testing machine | The testing machine can monitor the changes in friction force and the wear condition of the sample surface in real time during the test, and also p... |

Same products

| Air Permeability Tester STD- F8 | Seller: Standard International Group (HK) Limited | The Air Permeability Tester is designed to quickly and accurately measure the breathability and p... | |

| Surface Performance Tester STD-FB4 - A | Seller: Standard International Group (HK) Limited | Introduction TheSurface Tester analyzes finger movements-particularly, strokes-performed by arti... | |

| Compression Tester STD - FB3 - A | Seller: Standard International Group (HK) Limited | TheCompression Tester analyzes hand movements-particularly, pushing with a finger-performed by ar... | |

| Single - Strand Bending Tester STD - FB2 - SH | Seller: Standard International Group (HK) Limited | Standards ASTM A370. ASTM A416. ISO6934.4 The Single Fiber Bending Tester makes it possible to ... | |

| Bending Tester STD- FB2 - S | Seller: Standard International Group (HK) Limited | Compliance Standards ASTM D790 (Plastics Flexural Properties) ISO 178 (Flexural Strength of Rig... |