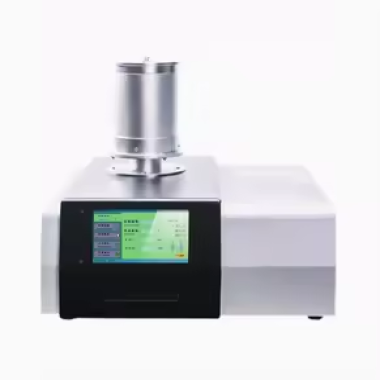

DSC Differential Scanning Calorimeter

The Differential Scanning Calorimeter (DSC) measures heat flow to/from a sample (1-10 mg) in a closed crucible within a temperature-controlled furnace, using a reference crucible. It operates in dynamic (constant heating rate) or isothermal (constant temperature) modes, measuring heat flow as a function of time and temperature.

Application:

It is used to analyze the thermal effect and corresponding temperature when the physical or chemical properties of organic and inorganic materials change under the program temperature control. It can test and analyze the melting point and enthalpy change of the sample, and can also be used to determine the time of automatic catalytic oxidation of the sample under the condition of normal temperature oxygen to evaluate the thermal stability of the sample, suitable for plastics and rubber materials.

Standard:

ASTM D3418 – Standard Test Method for Transition Temperatures and Enthalpies of Fusion and Crystallization of Polymers by Differential Scanning Calorimetry.

ASTM D3895 – Standard Test Method for Oxidative-Induction Time of Polyolefins by Differential Scanning Calorimetry.

ASTM D4419 – Standard Test Method for Measurement of Transition Temperatures of Petroleum Waxes by Differential Scanning Calorimetry.

ASTM D4591 – Standard Test Method for Determining Temperatures and Heats of Transitions of Fluoropolymers by Differential Scanning Calorimetry.

ASTM D5028 – Standard Test Method for Curing Properties of Pultrusion Resins by Thermal Analysis.

ASTM E793 – Standard Test Method for Enthalpies of Fusion and Crystallization by Differential Scanning Calorimetry.

ASTM E794 – Standard Test Method for Melting and Crystallization Temperatures By Thermal Analysis.

ASTM E1269 – Standard Test Method for Determining Specific Heat Capacity by Differential Scanning Calorimetry.

ASTM E1356 – Standard Test Method for Assignment of the Glass Transition Temperatures by Differential Scanning Calorimetry.

ASTM E1782 – Standard Test Method for Determining Vapor Pressure by Thermal Analysis.

ASTM E2160 – Standard Test Method for Heat of Reaction of Thermally Reactive Materials by DSC.

ASTM E2716 – Standard Test Method for Determining Specific Heat Capacity by Sinusoidal Modulated Temperature Differential Scanning Calorimetry.

GB/T17391-1998 –Test method for thermal stability of polyethylene pipes and fittings

1S011357-6 –:Plastics — Differential scanning calorimetry (DSC) — Part 6: Determination of oxidation induction time (isothermal OIT) and oxidation induction temperature (dynamic OIT)

ASMT D3895 –Standard Test Method for Oxidative Induction Time of Polyolefins by Differential Scanning Calorimetry (DSC)

GB/T –Plastics — Differential scanning calorimetry (DSC) — Part 3: Determination of temperature and enthalpy of melting and crystallization

1S011357-3 –Plastics — Differential scanning calorimetry (DSC) — Part 3: Determination of temperature and enthalpy of melting and crystallization

Features:

The instrument has stable performance, high precision and good repeatability!

Designed for measuring oxidation induction period in plastics and rubber industry:

Integrated design, temperature control and furnace device into one, reduce signal loss and interference, beautiful and exquisite appearance;

The furnace body adopts the upper cover structure, no need to lift the furnace body, convenient loading sample:

Equipped with standard material, users can carry out their own calibration of each temperature segment, reduce the error of the instrument;

High resolution data acquisition system, real-time data acquisition;

Intelligent adaptive monolithic microprocessor temperature control system, temperature control speed, high precision;

Perfect two-way atmosphere control system, using the original imported flow valve from the United States, can realize the automatic switching of ammonia to hydrogen in the measurement process:

Powerful management software to calculate oxidation induction period, epitaxial starting temperature, glass transition temperature, enthalpy variables. Enthalpy change ratio and other parameters;

Simple operation method, to achieve one-click testing, test results can be saved and printed:

Computer real-time display instrument status, test data and curves, easy to view.

Parameters:

| Description | Details |

|---|---|

| DSC ranges | ±10. +20. +40. +100. +160. +200mW (can be automatically switched) |

| Temperature range | RT - 500°C |

| Temperature accuracy | +0.1°C |

| Heating rate | 1 - 30°C/min |

| Gas supply system | Nitrogen, oxygen automatic switching (user-selectable) |

| Gas flow rate | ≤200ml/min |

| Gas pressure | 0.2MPa |

| Crucible material | Aluminum |

| Power supply | AC 220V 50Hz |

| Overall dimensions | 400x350x280mm |

| Weight | 10kg |

Accessoriess

Sample preparation press

Sealing lid and crucible gasket

Cleaning tool kit

DSC sensor

Heating furnace and main unit

Sample cell and reference cell

Aluminum crucible

Corundum crucible

High-pressure crucible

Reference material

Automatic sampler

Optical accessories

Evolved gas analysis interface

Test Procedures

Sample Preparation: Accurately weigh the sample, usually 5-20 milligrams, ensuring sample homogeneity and avoiding contamination.

Reference Material Selection: Select a suitable reference material, such as an inert material or a material with known thermal properties, for calibration and data comparison.

Experimental Condition Setting: Set the programmed heating conditions according to customer requirements; typically, the heating rate is 5°C/min.

Starting the Experiment: Start the DSC instrument and begin scanning, recording the real-time heat flow curve.

Data Analysis: Use the reference material data for baseline correction to eliminate the influence of instrument and environmental factors.

Result Interpretation: Interpret the experimental results based on the heat flow curve and the chemical and physical properties of the material.

Send product request

Other supplier products

| Gloss Meter | Standard The SpectroColor Pro S Series Gloss Meter adheres to stringent automotive interior quality control standards, includingISO 2813. ASTM D52... | |

| Full Notch Creep Tester | This testing machine is used to test the environmental stress cracking performance of plastic materials. The equipment features touchscreen operati... | |

| DSC Differential Scanning Calorimeter | The Differential Scanning Calorimeter (DSC) measures the heat flow to or from a sample under controlled heating conditions. A small amount of sampl... | |

| Rupture strength tester | The Rupture Strength Tester is designed to evaluate the mechanical pressure resistance and rupture strength of photovoltaic module components under... | |

| Safety shoe impact tester | According to the criteria Bs-953.1870 EN-344. ANSI-Z41 CSA-Z195 ISO K88782 EN ISO 20344. ANSI-Z41 BS EN-344 CSA-ZI95 LD50-1994 AS/NZS 22... |

Same products

| Air Permeability Tester STD- F8 | Seller: Standard International Group (HK) Limited | The Air Permeability Tester is designed to quickly and accurately measure the breathability and p... | |

| Surface Performance Tester STD-FB4 - A | Seller: Standard International Group (HK) Limited | Introduction TheSurface Tester analyzes finger movements-particularly, strokes-performed by arti... | |

| Compression Tester STD - FB3 - A | Seller: Standard International Group (HK) Limited | TheCompression Tester analyzes hand movements-particularly, pushing with a finger-performed by ar... | |

| Single - Strand Bending Tester STD - FB2 - SH | Seller: Standard International Group (HK) Limited | Standards ASTM A370. ASTM A416. ISO6934.4 The Single Fiber Bending Tester makes it possible to ... | |

| Bending Tester STD- FB2 - S | Seller: Standard International Group (HK) Limited | Compliance Standards ASTM D790 (Plastics Flexural Properties) ISO 178 (Flexural Strength of Rig... |