Vehicle Cabin Air Filter Tester

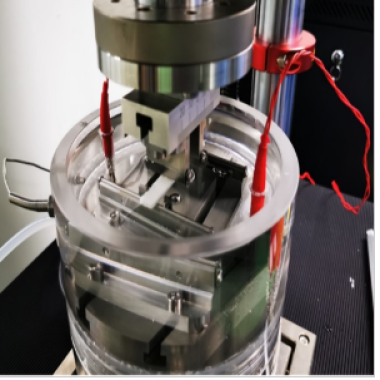

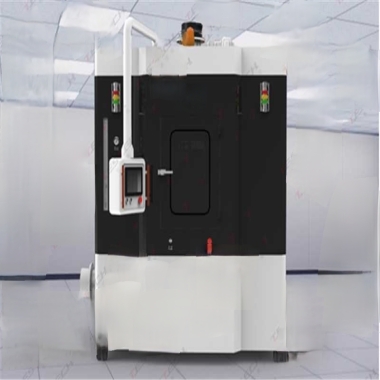

The Vehicle Cabin Air Filter Tester is a precision instrument designed to evaluate the filtration performance of passenger compartment air filters used in automobiles. It measures particulate matter filtration efficiency, pressure drop, and dust holding capacity, providing accurate and repeatable data essential for product development, quality control, and regulatory compliance. The tester combines advanced aerosol generation, dust dispersion, and particle counting systems to simulate real-world operating conditions and capture reliable performance indicators.

Application

This tester is widely used in automotive R&D centers, filter manufacturing facilities, quality control laboratories, and third-party testing institutions. It is suitable for testing cabin air filters of passenger vehicles, commercial vehicles, buses, and specialized transport equipment. The instrument evaluates filter performance under controlled airflow, particle loading, and environmental conditions, providing insights into efficiency, airflow resistance, and dust holding capacity. It supports product validation, development of high-efficiency filters, compliance verification with international standards, and routine quality assurance in production lines.

Standards

The Vehicle Cabin Air Filter Tester is designed in accordance with the following standards:

(1) DIN 71460-1: Road vehicles – Air filters for passenger compartments of motor vehicles – Part 1: particulate matter filtration tests

(2) ISO/TS 11155-1: Road vehicles – Air filters for occupants’ compartments – Part 1: particulate filtration test

(3) GB/T 14295-2019: Automotive air filter performance testing

(4) GB/T 13554-2020: Road vehicle air filter testing methodology

Product Features

(1) Generates and controls airflow rates from 70 to 700 m³/h to simulate real operating conditions.

(2) Accurately measures pressure drop across the filter from 0 to 1000 Pa.

(3) Provides a filter adapter to securely mount filters up to 300 × 600 mm in size.

(4) Standardized test section of 180 cm² ensures consistent airflow distribution.

(5) Integrated environmental sensors continuously monitor temperature, relative humidity, and atmospheric pressure.

(6) Dust disperser (SAG 410/L) delivers controlled dust load from 2 to 245 g/h.

(7) Aerosol generator (ATM 220) produces test aerosols for precise performance evaluation.

(8) Electrostatic neutralizer (EAN 581) removes charges from aerosols to ensure measurement accuracy.

(9) High-precision particle counter (TOPAS spectrometer LAP321) measures particle size and concentration.

(10) Automated control and data acquisition system supports test sequences, real-time monitoring, and reporting.

Technical Parameters

| Parameter | Specification |

|---|---|

| Air Flow Rate | 70–700 m³/h |

| Pressure Difference | 0–1000 Pa |

| Filter Adapter Size | 300 × 600 mm |

| Test Section Cross-Section | 180 cm² |

| Environmental Sensors | Temperature, Relative Humidity, Atmospheric Pressure |

| Dust Disperser | SAG 410/L (2–245 g/h) |

| Aerosol Generator | ATM 220 |

| Electrostatic Neutralizer | EAN 581 |

| Particle Measurement | Laser aerosols, TOPAS spectrometer LAP321 |

| Power Supply | 400 V AC, 16 A |

| Test Bench Dimensions | 460 × 120 × 340 cm (L × W × H) |

Accessories

(1) Dust disperser SAG 410/L

(2) Aerosol generator ATM 220

(3) Electrostatic neutralizer EAN 581

(4) TOPAS spectrometer LAP321 particle counter

(5) Filter adapters of various sizes

(6) Environmental monitoring sensors

Operation and Maintenance

(1) Install the filter securely on the adapter and ensure proper sealing.

(2) Set airflow, dust load, and test duration according to test requirements.

(3) Start the test bench and monitor environmental conditions in real-time.

(4) After completion, record efficiency, pressure drop, and dust holding capacity results.

(5) Clean the dust disperser, aerosol generator, and filter housing regularly to maintain accuracy.

(6) Calibrate particle counters and sensors periodically to ensure compliance with international standards.

Send product request

Other supplier products

| Battery Diaphragm Gas Permeability Tester | The Battery Diaphragm Gas Permeability Tester is a precision instrument designed to evaluate the gas permeability of battery diaphragms and separat... | |

| Absorbable Bone - connecting Plates Four - point Bending Tester | Standard ASTM F2119: Standard test method for constant load testing of bioabsorbable screws and washers, applicable to bending performance evalu... | |

| Syringe Sealing Negative Pressure Tester | The Syringe Sealing Negative Pressure Tester is a precision instrument designed to evaluate the integrity of syringe barrels under negative pressur... | |

| Helmet Surface Friction Testing Machine | A helmet surface friction testing machine is a device used to test the frictional force between the surface of a helmet and other objects. Its main... | |

| Vertical/Horizontal Wire Flame Test Apparatus UL 1581 | This testapparatus(VW-1)is designed according to UL1581 sect 1080.1~1080.14. and meet the criteria of VW-1(Vertical-specimen)FlameTest.It can be us... |

Same products

| Full-Body Garment Stress Tester,FZ/T 70015 | Seller: Standard International Group (HK) Limited | TheFull-Body Garment Stress Testeris a precision instrument designed to quantify the pressure exe... | |

| Industrial Dry Cleaning Machine,industrial garment steamer | Seller: Standard International Group (HK) Limited | TheIndustrial Dry Cleaning and Energy-Saving Dryer Machinesare designed for high-performance, rel... | |

| MST Medical Compression Stocking Tester,compression sock tester | Seller: Standard International Group (HK) Limited | The MST Medical Compression Stocking Tester is a professional instrument designed to evaluate the... | |

| MMT Liquid Water Separation Tester,MMT Liquid Water Analysis Tool | Seller: Standard International Group (HK) Limited | Applications Textile Manufacturing:Testing waterproof fabrics for outdoor gear R&D:Developi... | |

| Dental material color stability tester | Seller: Standard International Group (HK) Limited | Application The applications of color stability testers for dental materials are mainly reflecte... |