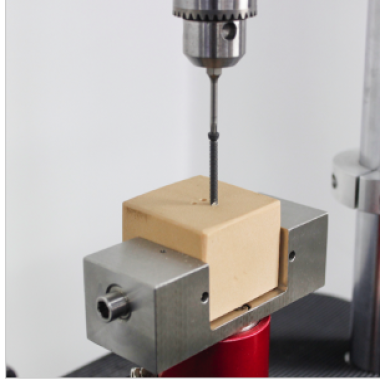

Rubber non-rotor vulcanization Tester

The Rubber Non-Rotor Vulcanization Tester is a precision instrument designed for the rubber processing industry to monitor and control rubber material quality. It provides rapid inspection and supports rubber basic research and formulation optimization. The tester can accurately measure scorch time, positive vulcanization time, vulcanization index, and torque parameters (maximum and minimum), offering essential data for quality control, R&D, and formula development.

Applications

(1) Rubber compound quality control: Rapid assessment of rubber material properties during production.

(2) Rubber R&D: Testing new rubber formulations and additives.

(3) Vulcanization process optimization: Determining optimal curing conditions.

(4) Material comparison: Evaluating performance differences between batches or suppliers.

(5) Rubber laboratory testing: Suitable for research institutes and industrial laboratories for basic rubber studies.

Standards

(1) ASTM D5289-95 — Standard Test Method for Rubber Property—Vulcanization Using a Moving Die Rheometer

(2) ISO 6502-1999(E) — Rubber, Vulcanized or Thermoplastic—Determination of Cure Characteristics

(3) GB/T 16584-1996 — Rubber—Determination of Cure Characteristics Using a Non-Rotating Rotor Rheometer

Advantages

(1) Accurate vulcanization measurement: Determines scorch time, positive cure time, vulcanization index, and torque with high precision.

(2) Supports formula optimization: Provides reliable data for rubber compound development.

(3) Standard compliant: Meets ASTM, ISO, and GB/T international and national standards.

(4) User-friendly operation: Simple control interface for temperature and time settings.

(5) Stable and durable: Designed for long-term use in laboratory and production environments.

Technical Parameters

| Item | Specification |

|---|---|

| Temperature measurement range | 0–200℃ |

| Temperature setting range | 0–200℃ |

| Temperature display range | 0–200℃ |

| Set time range | 0–200 minutes |

| Torque measuring range | 0–5 N·m, 0–10 N·m, 0–20 N·m |

| Swing frequency | 100 times/min (≈1.7 Hz) |

| Power supply | AC 220V ±10%, 50 ±1Hz, must be grounded |

| Compressed air | 0.32 MPa, controlled by pneumatic valve |

| Ambient conditions | Temperature 0–40℃, RH <80%, no corrosive gases |

Accessories

(1) Main tester ×1

(2) Pneumatic control valve ×1

(3) Power cable ×1

(4) Instruction manual ×1

Test Procedure

(1) Connect the power supply and compressed air source.

(2) Set the desired test temperature and curing time on the control panel.

(3) Load the rubber sample into the non-rotor rheometer cavity.

(4) Start the test; the swing mechanism will apply torque to the sample.

(5) Monitor the displayed data: scorch time, positive cure time, vulcanization index, and maximum/minimum torque.

(6) Stop the test after the set time, remove the sample, and record the results.

Maintenance Information

(1) Keep the instrument clean; remove rubber residues after each test.

(2) Periodically inspect the swing mechanism and torque sensor for wear or damage.

(3) Check temperature calibration regularly to ensure accurate measurements.

(4) Maintain pneumatic components, ensuring air lines and valves are free of leaks.

(5) Store in a dry, non-corrosive environment when not in use.

Send product request

Other supplier products

| Metal Bone Screws Torque Tester | Standard YY/T 1506. ASTM F543: The standard specifies the torque required to measure the torque required to screw a metallic bone grafting screw ... | |

| Solid Combustion Rate Tester | This product complies with "Recommendations on the Transport of Dangerous Goods - Manual of Tests and Criteria" 33.2.1.4 Test N.1: Test Method fo... | |

| Athletic Footwear Shock Attenuating Tester | The Athletic Footwear Shock Attenuating Tester is primarily used to test the shock energy absorption performance of single materials or material st... | |

| Wet Microbial Penetration Tester | The wet microbial penetration tester is mainly used to evaluate the barrier ability of medical protective equipment (such as surgical gowns, isolat... | |

| Foam Repeated Compression meter | Product Description: Foam repeated compression testing machine will accurately measure the thickness of the test piece, placed in the compression ... |

Same products

| Air Permeability Tester STD- F8 | Seller: Standard International Group (HK) Limited | The Air Permeability Tester is designed to quickly and accurately measure the breathability and p... | |

| Surface Performance Tester STD-FB4 - A | Seller: Standard International Group (HK) Limited | Introduction TheSurface Tester analyzes finger movements-particularly, strokes-performed by arti... | |

| Compression Tester STD - FB3 - A | Seller: Standard International Group (HK) Limited | TheCompression Tester analyzes hand movements-particularly, pushing with a finger-performed by ar... | |

| Single - Strand Bending Tester STD - FB2 - SH | Seller: Standard International Group (HK) Limited | Standards ASTM A370. ASTM A416. ISO6934.4 The Single Fiber Bending Tester makes it possible to ... | |

| Bending Tester STD- FB2 - S | Seller: Standard International Group (HK) Limited | Compliance Standards ASTM D790 (Plastics Flexural Properties) ISO 178 (Flexural Strength of Rig... |