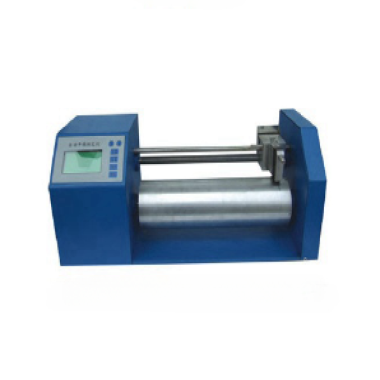

Diaper Anti-Side Leakage Performance Tester

The Diaper Anti-Side Leakage Performance Tester is designed to accurately measure the liquid loss of nonwoven materials and evaluate the anti-side leakage performance of diapers. It is widely used in the research and development, quality control, and performance testing of baby diapers, adult diapers, sanitary napkins, and other absorbent hygiene products. This instrument provides reliable, quantitative data to guide material design, production optimization, and product performance improvements.

Application

(1) Baby diapers, training pants, and pull-up diapers

(2) Adult incontinence diapers and absorbent briefs

(3) Sanitary napkins, panty liners, and menstrual products

(4) Absorbent underpads, bed pads, and protective sheets

(5) Nonwoven materials, superabsorbent polymers (SAP), and top sheet materials

(6) Liquid barrier and acquisition layers in diaper prototypes

(7) Laboratory testing of raw materials and finished products

(8) Production line quality control and pre-shipment inspection

Standards

The instrument is designed to meet multiple national and international standards, including:

(1) GB/T 28004.1-2021 — Diapers Part 1: Baby Diapers

(2) GB/T 28004.2-2021 — Disposable Diapers Part 2: Adult Diapers

(3) EDANA 152.0-99 — Absorbency Test Method for Nonwoven Materials

(4) ISO 9073-11 — Textiles — Test Method for Liquid Loss in Nonwovens

(5) ASTM F1911 — Standard Test Method for Absorbency of Disposable Hygiene Products

(6) JIS L 1096 — Testing Methods for Disposable Absorbent Products

Features

(1) Measures key liquid retention and leakage properties for accurate performance evaluation.

(2) Adjustable pressure and timing controls to simulate real usage conditions.

(3) Suitable for various product types, including baby and adult diapers, sanitary napkins, and absorbent pads.

(4) High-precision measurement ensures repeatable and reliable results.

(5) User-friendly interface for easy operation and monitoring.

Parameters

| Parameter | Specification |

|---|---|

| Test range | 0–500 ml (depending on instrument model) |

| Measurement accuracy | ±0.5 ml |

| Sample diameter | 40 mm |

| Test area | 20 cm² |

| Pressure range | 0–200 kPa (or higher) |

| Time control | 0–999 s |

| Power supply | AC 220V, 50/60 Hz |

| Overall dimensions | Dependent on model |

| Weight | Dependent on model |

Accessories

(1) Main unit ×1

(2) Sample holders ×2

(3) Instruction manual ×1

(4) Power cable ×1

(5) Calibration weights or pads (if applicable)

Test Procedures

(1) Prepare the sample and place it in the designated holder.

(2) Adjust the test pressure and set the required test time.

(3) Pour the standard test liquid onto the sample.

(4) Start the test and allow the instrument to measure liquid loss and side leakage.

(5) After the test, record the measurement data.

(6) Clean the sample holder and instrument surface before the next test.

Maintenance Information

(1) Regularly clean the sample holder, test platform, and liquid channels to prevent residue buildup.

(2) Check electrical connections and ensure proper grounding before operation.

(3) Calibrate the instrument periodically to maintain measurement accuracy.

(4) Avoid exposure to corrosive liquids or extreme environmental conditions.

(5) Replace worn or damaged parts promptly according to the manufacturer’s instructions.

Send product request

Other supplier products

| Photovoltaic module damp heat test chamber | The Photovoltaic Module Damp Heat Test Chamber is designed to simulate long-term tropical aging conditions for photovoltaic modules and related ele... | |

| In-situ expansion analysis system | The In-situ Expansion Analysis System is designed for high-precision measurement of dimensional and volumetric changes in electrochemical cells and... | |

| Ink drying apparatus meter | How it works: The working principle of the ink drying instrument is based on simulating the drying environment of the ink in the printing process,... | |

| Syringe Sealing Positive Pressure Tester | The Syringe Sealing Positive Pressure Tester is a precision instrument designed to evaluate the tight-fitting performance of disposable syringes. I... | |

| Safety Helmet Lateral Rigidity Tester | Standard GB 2812: Safety Helmets (China National Standard) Equivalent Compliance: ISO 6220-2 (Industrial Safety Helmets – Lateral Deformati... |

Same products

| Air Permeability Tester STD- F8 | Seller: Standard International Group (HK) Limited | The Air Permeability Tester is designed to quickly and accurately measure the breathability and p... | |

| Surface Performance Tester STD-FB4 - A | Seller: Standard International Group (HK) Limited | Introduction TheSurface Tester analyzes finger movements-particularly, strokes-performed by arti... | |

| Compression Tester STD - FB3 - A | Seller: Standard International Group (HK) Limited | TheCompression Tester analyzes hand movements-particularly, pushing with a finger-performed by ar... | |

| Single - Strand Bending Tester STD - FB2 - SH | Seller: Standard International Group (HK) Limited | Standards ASTM A370. ASTM A416. ISO6934.4 The Single Fiber Bending Tester makes it possible to ... | |

| Bending Tester STD- FB2 - S | Seller: Standard International Group (HK) Limited | Compliance Standards ASTM D790 (Plastics Flexural Properties) ISO 178 (Flexural Strength of Rig... |