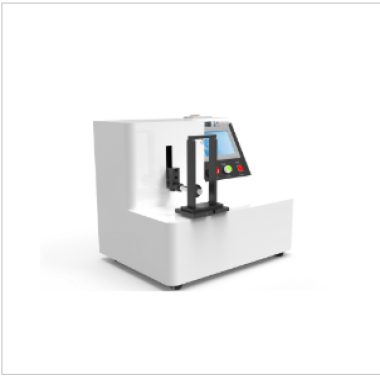

Suture Needle Cutting Force Tester

The Suture Needle Cutting Force Tester is a precision instrument specifically used to detect the force required by medical suture needles during the cutting process.

Applications

Evaluating Cutting Performance: By measuring the cutting force required for suture needles to penetrate simulated tissues, the cutting performance and stability of suture needles are evaluated. This is crucial for ensuring the effectiveness and safety of suture needles in actual surgeries. Quality Control: In the production process of medical devices, as a key tool for quality control, it is used to detect whether the cutting force of suture needles meets relevant standards and regulations.

R & D Support: During the R & D process of medical suture needles, the tester can provide key data support, helping researchers understand the impact of different materials, designs, and processes on the cutting force of suture needles, thus optimizing product performance. Product Certification: It provides the data support needed for product certification for manufacturers of medical suture needles, ensuring that products comply with relevant international or domestic standards and regulations.

Standards

YY/T 0043-2016:Medical suture needle

YY 0166-2002:Surgical suture needles with thread

Features

1. High Precision and High Repeatability

The testing instrument is equipped with high-precision sensors that can accurately capture force changes at the millinewton level. Combined with an advanced control system that precisely adjusts testing parameters, it ensures consistency of test data across multiple tests and different scenarios. This provides reliable data support for enterprise product quality control (eliminating defective products, reducing quality risks, and ensuring patient safety) and R&D optimization (scientific analysis and improved product performance).

2. Strong Flexibility

The testing parameters (speed, force) and clamp gripping force can be flexibly adjusted according to different specifications and designs of surgical needles, such as triangular and round needles. This allows for accurate evaluation of the cutting performance of various surgical needles while avoiding damage to the needle body. It is compatible with testing both conventional and new special surgical needles, assisting enterprises in efficient quality inspection and new product development.

3. User-Friendly Human-Machine Interface

It features an intuitive touchscreen/computer control interface, making operation simple and easy to understand; it supports automatic generation of standardized reports containing key data (puncture force, cutting force, etc.) and trend charts, saving labor and reducing errors. Some advanced models also support real-time data monitoring and remote transmission, facilitating timely problem handling and cross-regional data sharing.

Technical Parameters

| Serial No. | Parameter Item | Parameter Details |

|---|---|---|

| 1 | Operation Interface | Offers simplified Chinese/English selection; user-friendly and easy to operate |

| 2 | Measurement Range | 0 - 80N, with an error not exceeding ±0.1N (ensures measurement accuracy) |

| 3 | Testing Speed | ≤10mm/s (freely settable), simulating cutting speed in actual surgeries |

| 4 | Resolution | 0.01N (supports high-precision measurement for fine evaluation of suture needle cutting force) |

| 5 | Sensor | High-precision force value sensor (ensures measurement stability and reliability) |

| 6 | Display Screen | 7-inch high-resolution touch screen (directly displays test data and curves) |

| 7 | Programmable Controller | PLC/ARM (supports multiple testing modes and data processing functions) |

| 8 | External Dimensions | 430×290×250mm (specific dimensions may vary by model) |

| 9 | Power Supply | AC90V - 240V/50Hz (adaptive wide voltage, convenient for use across countries/regions) |

Accessoriess

Main unit × 1

Testing software × 1 (PC version)

Instruction manual / Operation manual × 1

Certificate of conformity / Warranty card × 1

Power cord × 1 (AC 90V-240V/50Hz adaptive)

Matching fixtures × 1 set (including various specifications)

Standard weights × 1 set (for calibration)

Printer paper × 1 roll

Suture thread × 1 roll (usually 4-0 or 3-0 gauge)

Wrench set × 1 (for fixture adjustment)

Test Procedures

1. Preparation Before Operation

Equipment and Environment Check:

Connect the power supply (compatible with AC90V-240V/50Hz wide voltage), start the device and confirm that the 7-inch touch screen (Chinese and English dual-language interface) is working properly; place the device on a vibration-free workbench at 22±2℃, ensuring that the testing environment meets the requirements for medical device testing.

Sample and Consumable Preparation:

Prepare surgical needles that comply with the standards of "YY/T 0043 Medical Suturing Needles" and "YY 0166 Suturing Needles with Thread" (no deformation, clean surface), and standard test sutures (such as 4-0 gauge, cut to 10cm length and folded into a U-shape).

2. Instrument Calibration (Ensuring Test Accuracy)

No-load Zero Point Calibration:

Ensure that there are no samples in the fixture, enter the device's "Calibration Interface" and perform zero point calibration, repeating 2-3 times to ensure that the sensor zero point error is ≤±0.1N (matching the instrument's measurement accuracy requirements).

Range Verification (Optional):

Verify the accuracy of the sensor measurement using standard weights (such as 5N, 10N) to ensure that the data meets the 0-80N range requirements.

3. Sample and Test Piece Installation

Fixture Adaptation:

Select the corresponding dedicated fixture according to the type of surgical needle (triangular needle/round needle), ensuring that the fixture matches the needle type.

Surgical Needle Fixing:

Install the surgical needle firmly in the fixture with the blade facing downwards, avoiding needle body shaking; if it is a suturing needle with thread, the root of the suture should be fixed simultaneously.

Test Wire Installation:

Hang the U-shaped test wire on the upper fixture, so that the wire is precisely aligned with the front 1/3 of the surgical needle blade, avoiding contact with other parts of the device.

4. Test Parameter Settings

Enter the touch screen operation interface and select the "Surgical Needle Cutting Force Test" mode;

Set the core parameters: test speed ≤10mm/s (simulating actual surgical cutting speed), number of tests (3-5 times are recommended, taking the average to improve data stability), ensuring that the parameters meet the requirements of the YY series standards;

Save the task after confirming the parameters. 5. Test Execution

Ensure personnel are away from the test area, then click "Start Test";

The instrument automatically drives the fixture to move, and a high-precision force sensor collects cutting force data in real time (including peak cutting force);

The equipment automatically stops after a single test is completed and records the data; repeat the test 3-5 times to obtain multiple sets of valid data.

6. Data Processing and Application

Data Viewing:

The touchscreen displays the peak cutting force, average cutting force, and force-displacement curve, allowing for intuitive assessment of the suture needle's cutting performance stability.

Report Generation:

Export a report containing test data that conforms to the YY series standards, for use in quality control (checking whether the cutting force meets the standards), R&D support (optimizing suture needle design), or product certification (providing compliance data).

Data Archiving:

Save the test report and raw data to complete record keeping.

7. Equipment Maintenance

After the test, turn off the power and clean the fixture and workbench (remove residual thread debris);

Regularly check the wear of the sensor and fixture to ensure the long-term stable operation of the equipment.

Send product request

Other supplier products

| Sauce Packet Pressure Testing Instrument | The pressure resistance tester for sauce packets is a device specifically designed to test the pressure - resistance performance of soft packaging ... | |

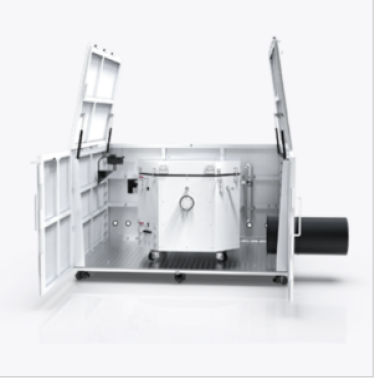

| Adiabatic Self - Accelerating Decomposition Temperature Tester | Product Introduction This product complies with "Recommendations on the Transport of Dangerous Goods - Manual of Tests and Criteria" 28.4.2 Test H... | |

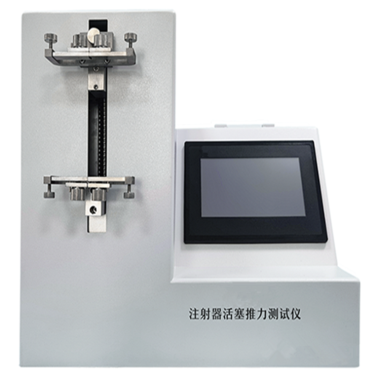

| Syringe piston thrust tester | Product introduction The syringe piston thrust tester is a kind of high precision and high stability measuring equipment, which is used to measure... | |

| Battery Adiabatic Calorimeter | Battery adiabatic calorimeters play a crucial role in battery research and development, providing essential thermodynamic data for safety assessmen... | |

| Minimum Ignition Temperature (MIT) – Dust Cloud Tester | Description Dust Cloud Minimum Ignition Temperature Tester is mainly used to assess the explosiveness of dust in the production and processing pla... |

Same products

| Full-Body Garment Stress Tester,FZ/T 70015 | Seller: Standard International Group (HK) Limited | TheFull-Body Garment Stress Testeris a precision instrument designed to quantify the pressure exe... | |

| Industrial Dry Cleaning Machine,industrial garment steamer | Seller: Standard International Group (HK) Limited | TheIndustrial Dry Cleaning and Energy-Saving Dryer Machinesare designed for high-performance, rel... | |

| MST Medical Compression Stocking Tester,compression sock tester | Seller: Standard International Group (HK) Limited | The MST Medical Compression Stocking Tester is a professional instrument designed to evaluate the... | |

| MMT Liquid Water Separation Tester,MMT Liquid Water Analysis Tool | Seller: Standard International Group (HK) Limited | Applications Textile Manufacturing:Testing waterproof fabrics for outdoor gear R&D:Developi... | |

| Dental material color stability tester | Seller: Standard International Group (HK) Limited | Application The applications of color stability testers for dental materials are mainly reflecte... |