Suture Needle Penetration and Bending Strength Tester

The Suture Needle Penetration and Bending Strength Tester is a device used to test the penetration performance and strength of medical suture needles. Designed and manufactured according to relevant standards ASTM F3014-2014 and ASTM F1874-98. this tester simulates the penetration process of a suture needle during actual use. Using a high-precision force sensor, it measures the force exerted on the needle tip as it penetrates simulated tissue, thereby evaluating the penetration performance and strength of the suture needle. It has wide applications in the medical, pharmaceutical, and quality control fields, and is crucial for ensuring the safety and effectiveness of surgical suturing procedures.

Applications

Quality Control for Manufacturing Enterprises: During the production of suture needles, the tester can conduct sampling tests on each batch of suture needles, promptly identifying quality issues in the production process, such as unstable raw material quality or defects in processing techniques. This enables timely adjustment of the production process to ensure the stability and consistency of product quality. Selecting Appropriate Suture Needles for Medical Institutions: Medical institutions can use the tester to conduct performance tests on different types of suture needles, and based on the test results, select the suture needles that best meet the surgical needs of patients, thereby improving surgical effectiveness and patient safety. Product R & D and Optimization: R & D personnel in the medical device field can use the tester to evaluate the performance of the design of new - type suture needles. By testing the strength and puncture force of suture needles with different structures, materials, and dimensions, they can optimize the design of suture needles and develop products with better performance.

Standards

The Suture Needle Puncture and Bending Strength Tester complies with relevant standards such as ASTM F3014 - 2014 and ASTM F1874 - 98. - ASTM F3014 - 2014: Specifies the specific methods and procedures for the penetration test of surgical suture needles, aiming to evaluate the penetration performance of suture needles to ensure they can meet requirements in actual use. - ASTM F1874 - 98: Specifies the specific methods and procedures for the bending test of surgical suture needles, aiming to evaluate the strength and durability of suture needles under bending conditions.

Features

Professional multi-station rotary testing system and bending strength testing system, suitable for puncture and bending strength testing of curved needles, straight needles, etc.

Simple and intuitive operation interface, convenient user-defined testing functions, and comprehensive data analysis and reporting functions.

Professional testing software with data analysis and reporting functions.

High-precision imported sensors for more accurate test results.

Real-time curve test data for easy identification of peaks and valleys.

The test platform has positioning holes for quick and accurate fixture installation.

Supports testing of various sample specifications; users can freely select different needle specifications.

Equipped with a handheld control box for quick adjustment of motor position.

Features automatic data storage and automatic power-off memory function.

Safety protection:

The software has an over-range pressure shutdown function to effectively protect the sensor.

Data security:

Equipped with a four-level user security password strategy to ensure the security of test data.

The computer software complies with GMP "Computerized Systems" requirements and has functions such as user management, permission management, and data audit trails.

Technical Parameters

| Serial No. | Parameter Item | Parameter Details |

|---|---|---|

| 1 | Testing Items | Puncture force, bending strength |

| 2 | Range | Customizable according to actual needs (e.g., 0 - 50N) |

| 3 | Stations | Multiple stations (adjustable per test requirements; e.g., 12 stations) |

| 4 | Accuracy | High-precision sensor; indication error ≤ 0.01N or 0.1%FS (full-scale range) |

| 5 | Needle-clamping Fixture | Fixtures for holding suture needles (e.g., 4°±2°/s, etc.); ensures stability and accuracy of suture needles during testing |

| 6 | Speed | Adjustable per actual needs; minimum: 10cm/min (4in/min), maximum: 30.5cm/min (12in/min) |

| 7 | Testing Rate | Speed when loading to set value ≤ 10mm/s |

| 8 | Power Supply | Usually 220V 50Hz; or other voltages/frequencies complying with local electrical standards |

Accessoriess

1. One main unit

2. One roll of printing paper

3. One set of clamps

4. One set of weights

5. One-year warranty

6. Operating instructions

7. Free lifetime instrument upgrade service according to standard specifications

Test Procedures

1. Preparation

Install the suture needle onto the testing equipment, ensuring the equipment is properly connected.

2. Setting Test Parameters

Set the relevant parameters for puncture force and bending performance testing according to the test requirements.

3. Starting the Test

Start the equipment to begin the puncture force and bending performance tests.

4. Data Processing

After the test is completed, the equipment will automatically record and display the test data. Users can analyze and process the data to obtain the performance indicators of the suture needle.

Send product request

Other supplier products

| 800L Water Cooled Xenon Lamp Testing Chamber | Water Cooled Xenon Lamp Testing Chamberis used to determine the color fastness and aging to sunlight, weather resistance, compound color fastness t... | |

| Flammability Tester STD-CFR 1610 | Product Introduction Model:STD-CFR 1610 Standards ASTMD 1230 ASTM F 963 ASTM F2100 -16 CFR PART 1610 Features 1.Stainless steel cabnet, beau... | |

| Stoll Quartermaster abrasion tester丨Stoll Quartermaster abrasion test chamber | The Stoll Quartermaster can conduct flat grinding, curved grinding, edge grinding, fold grinding and abrasion test such as frosting resistance, wel... | |

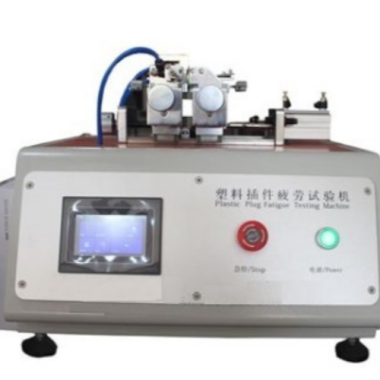

| Bag Plastic Buckle Durability Tester | It is mainly used to test the service life of plastic plug-ins in luggage accessories. Applications This machine simulates the use of plastic cla... | |

| Building Materials Monomer Combustion test Dust Removal Equipment | In a monomer combustion test, the material combustion can produce large amounts of smoke and dust, which pollutes the environment. Therefore, a sui... |

Same products

| Full-Body Garment Stress Tester,FZ/T 70015 | Seller: Standard International Group (HK) Limited | TheFull-Body Garment Stress Testeris a precision instrument designed to quantify the pressure exe... | |

| Industrial Dry Cleaning Machine,industrial garment steamer | Seller: Standard International Group (HK) Limited | TheIndustrial Dry Cleaning and Energy-Saving Dryer Machinesare designed for high-performance, rel... | |

| MST Medical Compression Stocking Tester,compression sock tester | Seller: Standard International Group (HK) Limited | The MST Medical Compression Stocking Tester is a professional instrument designed to evaluate the... | |

| MMT Liquid Water Separation Tester,MMT Liquid Water Analysis Tool | Seller: Standard International Group (HK) Limited | Applications Textile Manufacturing:Testing waterproof fabrics for outdoor gear R&D:Developi... | |

| Dental material color stability tester | Seller: Standard International Group (HK) Limited | Application The applications of color stability testers for dental materials are mainly reflecte... |