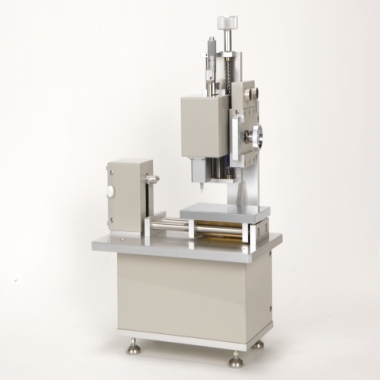

Catheter Leakage and Compliance Tester

The Catheter Leakage and Compliance Tester is a professional testing device used to evaluate the expansion capacity (compliance) and leak resistance of medical tubing (such as infusion lines, vascular catheters, and respiratory tubing) under varying pressure conditions.

Applications

The catheter leakage and compliance tester is mainly used to detect the leakage and compliance of medical catheters (such as the breathing circuits of ventilators and anesthesia machines). Specifically, it can: Leakage Test: By applying a certain pressure inside the catheter and monitoring the rate or extent of pressure drop, it determines whether there is leakage in the catheter. This is crucial for ensuring the sealing and safety of the catheter during medical procedures. Compliance Test: Compliance refers to the ability of the catheter to deform when subjected to external forces. The tester applies a certain pressure inside the catheter and measures the volume change of the catheter to evaluate its compliance. This is of great significance for understanding the flexibility and elasticity of the catheter, as well as its applicability in medical applications.

Standards

ISO 13988-1:2017: Intravascular catheters - Part 1

ISO 8536-4:2016: Medical infusion equipment

YY/T 0285.4-2017: Intravascular catheters - Part 4

YY/T 1551.1-2017: Non-intravascular catheters

Features

Color LCD large screen display: Real-time display of test data and statistical values, intuitive and clear.

Intelligent touch control operation: Simple human-machine interface for quick experiment switching.

High-precision electronic flow meter: Achieves precise flow control, avoiding testing errors.

Top-tier sensor system: High-sensitivity data acquisition ensures stable and consistent test results.

Data security management: Four-level access control and encrypted storage prevent unauthorized operations and ensure the integrity and traceability of results.

Convenient result output: Equipped with a micro printer, supporting instant printing of single test results and statistical data.

Technical Parameters

| Parameter | Specification |

|---|---|

| Pressure Range | Determined by test object & application scenarios:- e.g., 0 - 300kPa for medical breathing circuits- Narrower range (e.g., 0 - 50kPa) for routine compliance testing |

| Pressure Accuracy | Key for test accuracy; generally requires ±0.1% or higher (e.g., 0 - 50kPa pressure sensor can reach one-thousandth accuracy) |

| Flow Range | Covers various flow situations of tested catheters; common flowmeter range: 0 - 100L/min |

| Flow Accuracy | Important indicator; generally requires ±1% or higher (e.g., ±1%FS for 2L/min mass flow controller) |

| Volume Measurement Range and Accuracy | - Range: From a few milliliters to several liters (adapts to different catheter volumes)- Accuracy: Generally needs to reach ±0.1ml or higher (to accurately calculate catheter compliance) |

| Test Time Range | - Leakage tests: Flexible setting (a few seconds to several hours)- Compliance tests: Controls pressure change rate & time interval to capture catheter volume changes at different pressure stages |

Accessoriess

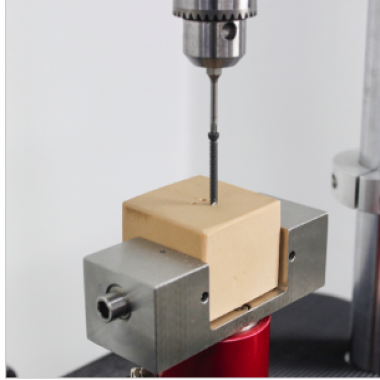

Standard accessories include: specialized connectors for different sizes of medical tubing (such as ventilator/anesthesia machine breathing circuits), pressure/flow test tubing, tubing fixing clamps (to ensure sample stability during testing), standard test samples for equipment calibration (including standard leakage and compliance components), operating manual, and calibration certificate.

Test Procedures

Sample Pretreatment

Tubing Aging Treatment: Immerse in physiological saline at 37°C for 24 hours to relieve material stress;

Connection Sealing Inspection: Apply soapy water to the interfaces to confirm no initial leakage.

Typical Test Modes

Static Compliance Test:

Pressurize to 100kPa, maintain pressure for 30 seconds, and record the volume change ΔV1;

Release pressure to 0kPa, and record the volume recovery ΔV2;

Compliance calculation: C = (ΔV1 - ΔV2)/ΔP (unit: mL/kPa).

Dynamic Leakage Test:

Apply a sinusoidal pressure wave with a frequency of 1Hz and an amplitude of ±50kPa for 10 minutes;

Collect the leaked fluid and calculate the leakage rate using the weighing method (≤0.5mL/10min is considered acceptable).

Result Evaluation Standards (Refer to YY/T 0285.4-2017)

Compliance Deviation: ≤±15% compared to the nominal value;

Leakage: ≤1mL/minute under positive pressure of 100kPa, and no visible bubbles under negative pressure of -50kPa.

Send product request

Other supplier products

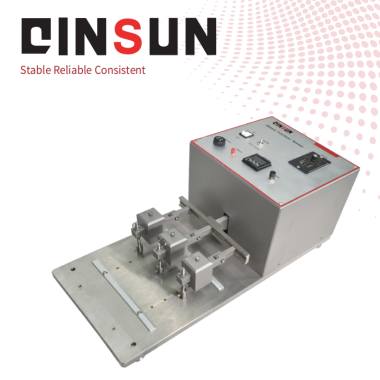

| Precision Fiber Slicer | G214Precision Fiber Slicer is used to make the accurate fiber cross-sectional specimens for further inspection or research under the microscope. In... | |

| KES-SESRU surface roughness/friction tester | TheRoughness/Friction Tester analyzes hand movements-particularly, strokes-performed by artisans and professionals when judging a fabric' s texture... | |

| Wool Shrinkage Tester | YM116 type wool fold shrinkage tester is a precision instrument to determine the length of the towel under the standard tension. The instrument ad... | |

| Metal Bone Screws Torque Tester | Standard YY/T 1506. ASTM F543: The standard specifies the torque required to measure the torque required to screw a metallic bone grafting screw ... | |

| Glass Scratch/Abrasion Tester | The Glass Scratch/Abrasion Tester is used to test the scratch and abrasion resistance of glass. This instrument uses a counter to set the number of... |

Same products

| Full-Body Garment Stress Tester,FZ/T 70015 | Seller: Standard International Group (HK) Limited | TheFull-Body Garment Stress Testeris a precision instrument designed to quantify the pressure exe... | |

| Industrial Dry Cleaning Machine,industrial garment steamer | Seller: Standard International Group (HK) Limited | TheIndustrial Dry Cleaning and Energy-Saving Dryer Machinesare designed for high-performance, rel... | |

| MST Medical Compression Stocking Tester,compression sock tester | Seller: Standard International Group (HK) Limited | The MST Medical Compression Stocking Tester is a professional instrument designed to evaluate the... | |

| MMT Liquid Water Separation Tester,MMT Liquid Water Analysis Tool | Seller: Standard International Group (HK) Limited | Applications Textile Manufacturing:Testing waterproof fabrics for outdoor gear R&D:Developi... | |

| Dental material color stability tester | Seller: Standard International Group (HK) Limited | Application The applications of color stability testers for dental materials are mainly reflecte... |