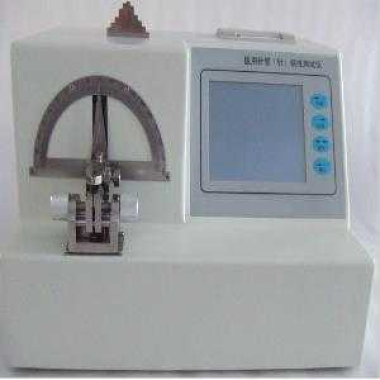

Medical needle toughness tester

The Medical Needle Toughness Tester is designed to evaluate the mechanical strength and flexibility of medical needles under bending stress. It features a 5.7-inch LCD touch display (120 × 90 mm) and supports testing of three types of needle walls: normal, thin, and ultra-thin. The device is manufactured in compliance with GB18457 (“Stainless steel needle for medical equipment manufacturing”), GB15811 (“Sterile disposable injection needle”), and ISO 9626 standards.

This tester is ideal for R&D, quality control, and production verification of disposable medical needles.

Application

(1) Medical disposable injection needles – evaluating bending durability before packaging.

(2) Insulin pen needles – testing ultra-thin walls for high flexibility without fracture.

(3) Vacutainer blood collection needles – ensuring mechanical reliability during insertion.

(4) IV infusion needles and cannulas – verifying structural integrity under repeated bending stress.

(5) Specialty surgical needles – quality assurance for orthopedic or microsurgical applications.

Standards

The device meets and supports testing according to the following international and national standards:

(1) GB15811 – Sterile disposable injection needle

(2) GB18457 – Stainless steel needle for medical equipment manufacturing

(3) ISO 9626 – Stainless steel needle for medical use

Features

(1) High-precision touch LCD interface for intuitive operation.

(2) Adjustable bending angles for normal, thin, and ultra-thin needle walls.

(3) Automatic bi-directional bending for standardized toughness testing.

(4) High-brightness 4-digit LED display for accurate parameter monitoring.

(5) Supports multiple syringe diameters (0.2–3.4 mm).

(6) Compact and robust design with net weight of 10 kg.

(7) Free perpetual upgrades according to national standards.

(8) Complete accessory kit included for immediate testing.

Test Procedure

(1) Fix one end of the needle tube firmly in the jig.

(2) Adjust the span according to needle wall type:

Normal wall: 25° bending

Thin wall: 20° bending

Ultra-thin wall: 15° bending

(3) Apply force at the specified span position, bi-directionally, 20 times at a frequency of 0.5 Hz.

(4) Observe the needle for breakage, deformation, or failure.

Principle: One end of the needle is fixed. A force is applied from the fixed point to the prescribed span, bending in one direction and then in the opposite direction, repeated for the defined number of cycles.

Technical Parameters

| Parameter | Specification |

|---|---|

| Syringe nominal specifications | 0.2 – 3.4 mm |

| Test frequency | 0.5 Hz |

| Rocker arm bending angle | 15°, 20°, 25° (switch selectable, displayed on high-brightness 4-digit LED) |

| Bending distance | 6 – 95 mm, accuracy ±0.1 mm (10 selectable spans) |

| Number of experiments | Bi-directional force 20 times |

| Net weight | 10 kg |

| Overall dimensions (L × W × H) | 300 × 240 × 240 mm |

| Standards | GB15811, GB18457, ISO 9626 |

| Control & Display | 5.7-inch LCD touch menu (120 × 90 mm) |

| Upgrade | Free perpetual upgrade according to national standards |

| Power supply | AC 220 V, 50 Hz |

| Part List | Host (1 set), Printing paper (1 roll), Fixture (1 set), Weight (1 set), Operating Instructions |

Accessories

(1) Printing paper (1 roll)

(2) Needle fixture (1 set)

(3) Weight set for bending calibration

(4) Operating instructions in English/Chinese

Maintenance Information

(1) Keep the device clean and dry; wipe with a soft cloth after use.

(2) Check the calibration of bending angles and LED display periodically.

(3) Avoid impact or vibration to ensure precise mechanical performance.

(4) Follow local electrical safety standards for power supply and grounding.

Send product request

Other supplier products

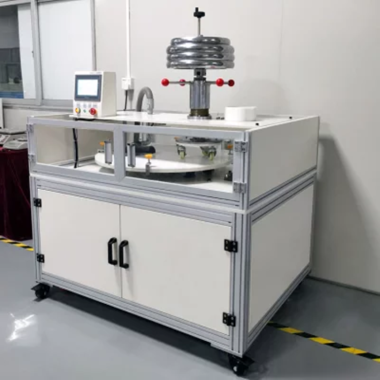

| Micro Controll Constant-Speed Friction Plate Tester | A friction and wear testing machine is a device composed of a test force loading system, a friction force measuring system, an experimental clampin... | |

| Weatherometer Laboratory Testing Equipment(UV) | Features and Benefits 1. UVA-340. UVB-313 and other UV lamps, a single power of 40 watts, can accurately control the irradiation intensity of 0.15... | |

| Syringe needle flow tester | The Syringe Needle Flow Tester is designed to evaluate the flow characteristics of syringes by measuring the volume of liquid discharged over a spe... | |

| Large diameter blasting test machine | The large-diameter blasting test machine can perform continuous (linear) pressure testing of pipes according to ASTM D 1599 standard. The pressuriz... | |

| Floor Caster Wear Tester | The Floor Caster Wear Tester is designed to evaluate the wear resistance of chair casters on various floor coverings, including resilient and lamin... |

Same products

| Air Permeability Tester STD- F8 | Seller: Standard International Group (HK) Limited | The Air Permeability Tester is designed to quickly and accurately measure the breathability and p... | |

| Surface Performance Tester STD-FB4 - A | Seller: Standard International Group (HK) Limited | Introduction TheSurface Tester analyzes finger movements-particularly, strokes-performed by arti... | |

| Compression Tester STD - FB3 - A | Seller: Standard International Group (HK) Limited | TheCompression Tester analyzes hand movements-particularly, pushing with a finger-performed by ar... | |

| Single - Strand Bending Tester STD - FB2 - SH | Seller: Standard International Group (HK) Limited | Standards ASTM A370. ASTM A416. ISO6934.4 The Single Fiber Bending Tester makes it possible to ... | |

| Bending Tester STD- FB2 - S | Seller: Standard International Group (HK) Limited | Compliance Standards ASTM D790 (Plastics Flexural Properties) ISO 178 (Flexural Strength of Rig... |