6-12-24 Station Bally Flex Tester

Introduction

In daily life, leather products, such as leather clothing, purses, leather shoes ,etc., produce friction with their own or human body and lead to color fading. This instrument is used to test the rubbing fastness of leather surface under dry friction and wet friction as well as other test conditions.

Basic principles: the square wool felt on friction head (with or without extra balance weights) makes reciprocating friction with leather (stretched or not stretched) on the friction platform for reciprocating friction. After a certain number of friction times, compare the wool felt with gray card and rate the color fastness level.

Standards

ISO 11640 Leather -- Tests for colour fastness -- Colour fastness to cycles of to-and-fro rubbing.

SATRA PM 173 Reference standard of footwear testing content and methods.

QB/T 2537-2001 Leather -- Tests for colour fastness --Colour fastness to reciprocating rubbing.

DIN 4843 Safety Footwear; Safety Requirements, Testing

QB/T 2226 Shoelace wear test method, light industry standards.

GB/T 20991-7.3Personal protective footwear test method.

Consumables

Friction material:

White wool felt, size 15mm × 15mm. The punched pure wool felt piece should meet the following requirements: pH of water extract between 5.5 ~ 7.0; mass per unit area (1750 ± 100) g / m2, thickness (5.5 ± 0.5) mm.

Technical Parameters

1, Test bench: a horizontal metal platform; a holder for fastening the leather to the platform, leaving approximately 80mm exposed; a device with which the leather may be extended 10% to 20% linearly in the direction of rubbing (sample size 120mm × 20mm).

2, Test column: weight (500 ± 25) g. It can be moved, but also firmly fixed. including:

A) Test head area: 15mm × 15mm;

B) Device for adjusting the test head to bring the felt pad into horizontal contact with the test platform;

C) Load bearing blocks: (500 ± 10) g. After loading, the total mass of the test column is 1000g;

D) Adjustment device: adjust the test column up and down so that the test head makes horizontal contact with sample.

3, Device that drives test bench for reciprocating motion: test head makes forward-backward motion with a stroke of 35mm ~ 40mm at a frequency of (40 ± 2) cycles / min.

4, Counter: LCD digital display, round-trip as one time, the number of cycles can be set to 5 to 500 times.

5, Device that can adjust the test column in the horizontal direction (optional): the test head can be rubbed against the leather samples at 2 to 3 different angles.

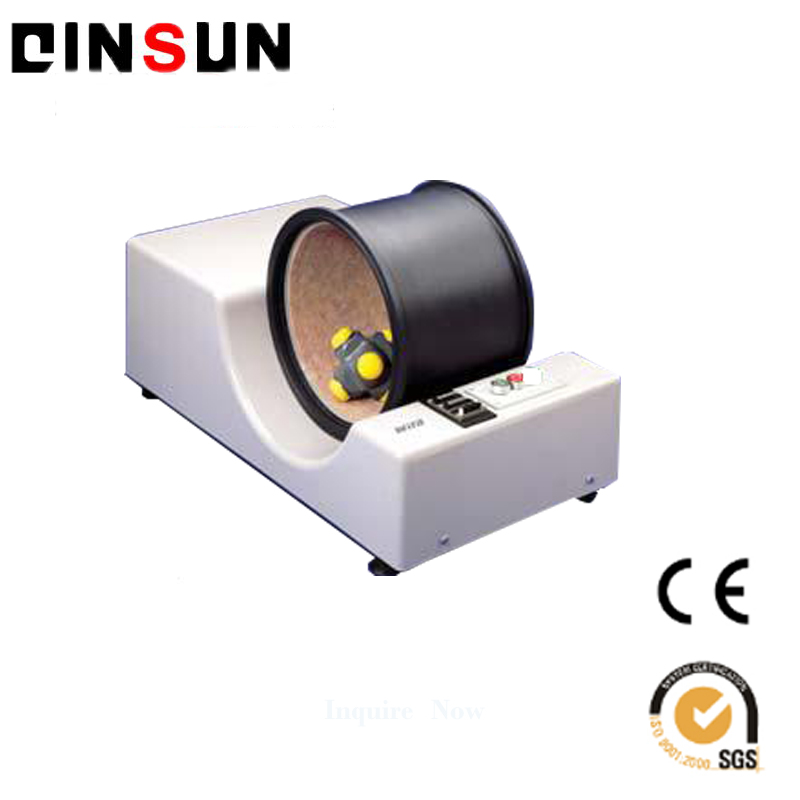

Product Display

Product Display

![]()

In daily life, leather products, such as leather clothing, purses, leather shoes ,etc., produce friction with their own or human body and lead to color fading. This instrument is used to test the rubbing fastness of leather surface under dry friction and wet friction as well as other test conditions.

Basic principles: the square wool felt on friction head (with or without extra balance weights) makes reciprocating friction with leather (stretched or not stretched) on the friction platform for reciprocating friction. After a certain number of friction times, compare the wool felt with gray card and rate the color fastness level.

Standards

ISO 11640 Leather -- Tests for colour fastness -- Colour fastness to cycles of to-and-fro rubbing.

SATRA PM 173 Reference standard of footwear testing content and methods.

QB/T 2537-2001 Leather -- Tests for colour fastness --Colour fastness to reciprocating rubbing.

DIN 4843 Safety Footwear; Safety Requirements, Testing

QB/T 2226 Shoelace wear test method, light industry standards.

GB/T 20991-7.3Personal protective footwear test method.

Consumables

Friction material:

White wool felt, size 15mm × 15mm. The punched pure wool felt piece should meet the following requirements: pH of water extract between 5.5 ~ 7.0; mass per unit area (1750 ± 100) g / m2, thickness (5.5 ± 0.5) mm.

Technical Parameters

1, Test bench: a horizontal metal platform; a holder for fastening the leather to the platform, leaving approximately 80mm exposed; a device with which the leather may be extended 10% to 20% linearly in the direction of rubbing (sample size 120mm × 20mm).

2, Test column: weight (500 ± 25) g. It can be moved, but also firmly fixed. including:

A) Test head area: 15mm × 15mm;

B) Device for adjusting the test head to bring the felt pad into horizontal contact with the test platform;

C) Load bearing blocks: (500 ± 10) g. After loading, the total mass of the test column is 1000g;

D) Adjustment device: adjust the test column up and down so that the test head makes horizontal contact with sample.

3, Device that drives test bench for reciprocating motion: test head makes forward-backward motion with a stroke of 35mm ~ 40mm at a frequency of (40 ± 2) cycles / min.

4, Counter: LCD digital display, round-trip as one time, the number of cycles can be set to 5 to 500 times.

5, Device that can adjust the test column in the horizontal direction (optional): the test head can be rubbed against the leather samples at 2 to 3 different angles.

Product Display

Introduction

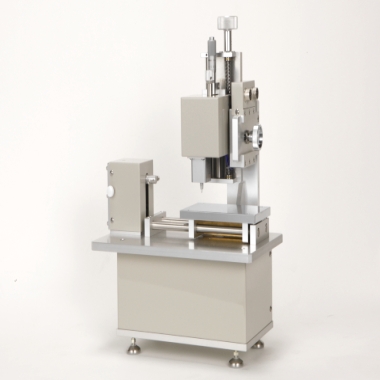

Bally flex tester is designed to evaluate the flexural resistance of leather to continual flexure. The 12-station flex tester is a popular model. The user can easily change the station arrangement, take and install samples. The whole tester is of stainless steel structure. Digital counter can preset the running times so that the instrument automatically stops when reaching the set values with no need of staff to attend to.

Application

Bally flex tester is designed to evaluate the flexural resistance of leather to continual flexure. It is an universal instrument to assess the flexural resistance of all kinds of light leathers and surface trim, as well as to evaluate the specimen’s propensity to crack,similar to the crease that forms in a shoe's upper that flexes during walking. The flexing mechanism of the Bally flex tester is different from that of the shoe upper flex tester. The functions of two testers complement mutually. The tester is also used for the pretreatment of specimens prior to the determination of water vapor permeability– especially of shoe upper materials used for protective footwear.

Standards

EN ISO 20344:6.6 Personal Protective Equipment - Test Methods For Footwear

UNI 4818 Polymeric materials coated fabrics. Test methods

DIN 53.351 Inspection of leather, artificial leather and similar flat fabrics

UNE/I.U.P.20, I.U.P.10+20, I.U.P.20

Features

1. The machine is simple to use, installed on the table, and can plug in anytime.

2. There are 12/24 -station models, also available for low temperature models (up to -20 ° C). The temperature values vary depending on the ambient temperature of the machine.

3. Two types of selective test stations to test multiple samples at a time with a high degree of stability.

4. The control panel has a high degree of automation, easy operation.

Technical Parameters

Bally flex tester is designed to evaluate the flexural resistance of leather to continual flexure. The 12-station flex tester is a popular model. The user can easily change the station arrangement, take and install samples. The whole tester is of stainless steel structure. Digital counter can preset the running times so that the instrument automatically stops when reaching the set values with no need of staff to attend to.

Application

Bally flex tester is designed to evaluate the flexural resistance of leather to continual flexure. It is an universal instrument to assess the flexural resistance of all kinds of light leathers and surface trim, as well as to evaluate the specimen’s propensity to crack,similar to the crease that forms in a shoe's upper that flexes during walking. The flexing mechanism of the Bally flex tester is different from that of the shoe upper flex tester. The functions of two testers complement mutually. The tester is also used for the pretreatment of specimens prior to the determination of water vapor permeability– especially of shoe upper materials used for protective footwear.

Standards

EN ISO 20344:6.6 Personal Protective Equipment - Test Methods For Footwear

UNI 4818 Polymeric materials coated fabrics. Test methods

DIN 53.351 Inspection of leather, artificial leather and similar flat fabrics

UNE/I.U.P.20, I.U.P.10+20, I.U.P.20

Features

1. The machine is simple to use, installed on the table, and can plug in anytime.

2. There are 12/24 -station models, also available for low temperature models (up to -20 ° C). The temperature values vary depending on the ambient temperature of the machine.

3. Two types of selective test stations to test multiple samples at a time with a high degree of stability.

4. The control panel has a high degree of automation, easy operation.

Technical Parameters

| Items | Parameters |

| Flexing angel | 22.5° |

| Speed | 100±5cpm |

| Instrument material | Stainless steel |

| Surface treatment | Paint spraying |

| External dimension | 85.6×52×38cm(L×W×H) |

| Weight | 41kg |

| Power supply | 220V,50Hz,1A |

Product Display

Send product request

Other supplier products

| CROSS HATCH ADHESION TESTER to test automotive interior materials | Crosshatch scratch tester/Scratch tester makes contacting relative motion between the scratching head and material surface for the evaluation of th... | |

| Hexapod Tumbler Carpet Tester | IntroductionThe steel ball or the hexagonal feet randomly roll in the rotating drum, which is covered with carpet textile samples. Observe the appe... | |

| hydrostatic pressure tester For textile fabric Protective Clothing testing | The hydrostatic head tester can be used for waterproof moisture permeability testing of high density fabrics, laminated fabrics, coated fabrics and... | |

| Single Fiber Strength Tester | The single fibers are stretched to break on a constant elongation extensometer (CRE) under specified conditions. The values of tensile strength, el... | |

| Oscillatory And Wyzenbeek Abrasion Tester | Wyzenbeek Abrasion Tester, made of modern ergonomic design, is to determine the abrasion resistance of fabrics when rubbed against a standard abras... |

Same products

| Gas Oxidizing Property Tester | Seller: Standard International Group (HK) Limited | Product Description Conforms to ISO 10156-2010 “Gases and Gas Mixtures Selection of Cylind... | |

| Battery Powder Compaction Density Measurement System | Seller: Standard International Group (HK) Limited | The Battery Powder Compaction Density Measurement System is a precision testing system designed... | |

| Battery Powder resistance tester | Seller: Standard International Group (HK) Limited | The Powder Resistivity Meter is a precision testing system designed to measure electrical resisti... | |

| KES-SESRU surface roughness/friction tester | Seller: Standard International Group (HK) Limited | TheRoughness/Friction Tester analyzes hand movements-particularly, strokes-performed by artisans ... | |

| Air Permeability Tester STD- F8 | Seller: Standard International Group (HK) Limited | The Air Permeability Tester is designed to quickly and accurately measure the breathability and p... |