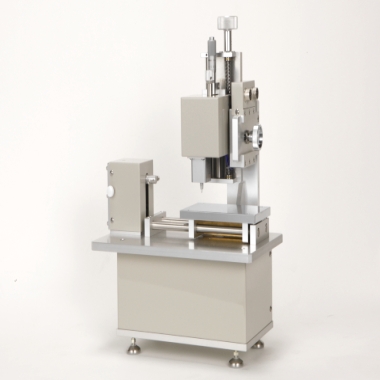

Adiabatic Accelerated Calorimeter

An Accelerating Rate Calorimeter (ARC) is a high-precision thermal analysis instrument that assesses the thermal decomposition behavior and safety risks of chemical substances by monitoring sample temperature, pressure, and thermodynamic parameters in real time under adiabatic conditions.

Application

Battery Safety Research: Evaluating the thermal runaway characteristics of batteries under abusive conditions, providing key parameters of the thermal runaway process, such as self-heating onset temperature and thermal runaway initiation temperature.

Material Thermal Stability: Studying the thermal stability and thermal decomposition behavior of materials, and evaluating the thermal safety of materials.

Chemical Reaction Thermal Analysis: Analyzing the thermal effects of chemical reactions, providing thermodynamic parameters such as reaction heat and activation energy.

Safety Standard Development: Assisting in determining the safe operating range and runaway hazards of materials and products, providing references for the development of safety standards.

Standards

T/CIS 17007-2023:

Since "T/CIS" is not a widely - known, globally standardized prefix like some international or well - recognized national standard - setting body abbreviations, without specific context about the issuing organization (CIS here might refer to a certain industry association or similar entity in China), a general way to name it could be "Technical Specification T/CIS 17007 - 2023" (assuming it is a technical specification; if it's a different type of standard, the description before the number can be adjusted accordingly).

JJF 1059.1-2012:

Evaluation and Expression of Uncertainty in Measurement - Part 1: General Rules (JJF is the code for metrological verification regulations in China, and this standard is about the evaluation and expression of measurement uncertainty)

JJF 1001-2011:

General Terms in Metrology and Their Definitions (JJF 1001 is a fundamental standard in the field of metrology in China that defines general metrological terms)

Features

1. Supports Heating - Waiting - Scanning (HWS) mode, constant - temperature mode, isochronous scanning mode, etc. 2. Equipped with professional data - analysis software, enabling automatic calculation of parameters such as exothermic onset temperature, adiabatic temperature rise, activation energy, and pre - exponential factor.

3. The software integrates the safety risk assessment methods and standards for reactions in the *Guidelines for Safety Risk Assessment of Fine Chemical Reactions* issued by the former State Administration of Work Safety, enabling one - stop assessment of the hazard level of reaction processes.

4. Key components are from well - known international brands, ensuring the long - term and stable operation of the instrument.

5. After the experiment, an inert gas can be introduced to rapidly cool down the furnace body.

6. Features an experimental status indication function, as well as overpressure and over - temperature alarm functions.

7. The furnace cover has an automatic lifting function, ensuring safety and facilitating operation.

8. With professional industrial design, it is simple and elegant, has a user - friendly human - machine interaction, and is easy to learn, understand, and operate.

9. The data - analysis software incorporates the differential conversion - rate thermodynamics calculation method, which has significant advantages in the calculation of the thermal decomposition kinetics of mixed materials and the prediction of thermal hazards.

Parameters

|

Operating Environment |

(5~40)℃, <85%RH |

|

Temperature Control Range |

Room temperature~500℃ |

|

Temperature Detection Threshold |

(0.005~0.02)℃/min |

|

Temperature Tracking Rate |

(0.005~40)℃/min |

|

Temperature Display Resolution |

0.001℃ |

|

Pressure Range |

Maximum withstand pressure 20MPa |

|

Pressure Resolution |

1kPa |

|

Sample Cell Specifications |

8mL |

|

Sample Cell Material |

Stainless steel, titanium, Hastelloy (optional) |

|

Phi Value |

≤1.35 |

|

Interfaces |

USB or RJ45 |

|

Power Supply |

AC220V/50Hz |

|

Power |

≤3000W |

|

Dimensions |

620mm*470mm *670mm |

|

Weight |

Approx. 78kg |

Accessoriess

Core measurement system components

Temperature control and insulation system components

Sample handling system components

Safety and protection system components, etc.

Test Procedures

Preparation before operation: Operators should wear appropriate work clothes, gloves, and safety glasses, as well as other personal protective equipment. Operators must understand the working principle of the instrument, its operating procedures, and the corresponding experimental procedures.

Experimental operation: Operators must place the test substance, samples, and test tubes in the sample chamber of the adiabatic accelerating calorimeter according to the instructions or experimental requirements. The use of excessive reagents is prohibited during the experiment.

Experimental precautions: Touching the high-temperature samples inside the sample chamber during the experiment is prohibited. After the experiment is completed, the instrument power should be turned off, all connecting lines should be disconnected, and the adiabatic accelerating calorimeter should be properly cleaned for future use.

Data recording and analysis: By connecting to a computer or data logger, the instrument can display the temperature change curve during the reaction in real time.

Send product request

Other supplier products

| Photo fill light box | Standard CE & FCC Certified: Meets electromagnetic compatibility and safety standards for EU/US markets. RoHS Compliant: Lead-free constructi... | |

| Incline Impact Tester | The Incline Impact Tester is designed to evaluate the impact resistance of products, packaging, and transport systems under controlled oblique load... | |

| Digital display electronic ink viscosity meter | How it works: The working principle of the digital display electronic ink viscosity meter is based on two tin (usually a metal roller and a rubber... | |

| UV curing light box | Standard ISO 10977: Adheres to industrial standards for UV curing of adhesives and coatings. ASTM E3022: Meets requirements for radiometric measu... | |

| Carbon Arc Aging Chamber | Carbon arc aging chamber is mainly used to simulate the destructive effects of ultraviolet rays, temperature, humidity and other factors in natural... |

Same products

| Gas Oxidizing Property Tester | Seller: Standard International Group (HK) Limited | Product Description Conforms to ISO 10156-2010 “Gases and Gas Mixtures Selection of Cylind... | |

| Battery Powder Compaction Density Measurement System | Seller: Standard International Group (HK) Limited | The Battery Powder Compaction Density Measurement System is a precision testing system designed... | |

| Battery Powder resistance tester | Seller: Standard International Group (HK) Limited | The Powder Resistivity Meter is a precision testing system designed to measure electrical resisti... | |

| KES-SESRU surface roughness/friction tester | Seller: Standard International Group (HK) Limited | TheRoughness/Friction Tester analyzes hand movements-particularly, strokes-performed by artisans ... | |

| Air Permeability Tester STD- F8 | Seller: Standard International Group (HK) Limited | The Air Permeability Tester is designed to quickly and accurately measure the breathability and p... |