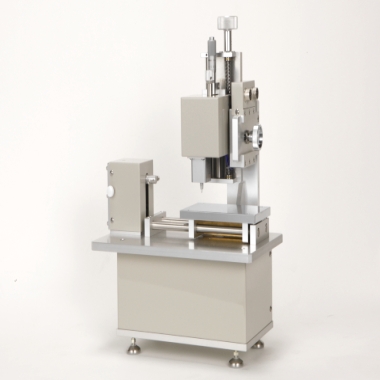

20L Spherical Explosion Tester

20L Spherical Explosion Tester is characterized by accurate test data and ease of use. Its through the compressed air will be a certain mass of dust specimen diffusion to the 20L spherical explosion container, the use of specified energy of the chemical ignition head or electrostatic ignition head of the dust cloud ignition, measurement of the explosion container in the pressure and time change curve, to obtain the maximum explosion pressure in the test and the maximum rate of rise of pressure, and then calculated to get the explosion index. Maximum explosion pressure, maximum explosion pressure rise rate and explosion index and other parameters can be used for explosion relief design and explosion suppression design. The instrument is mainly used for dust explosivity assessment in production and processing places such as aluminum powder, zinc powder, plastic powder, intermediates of organic synthetic drugs, wheat flour, sugar, wood chips, dyes, glue wood ash, milk powder, tea powder, tobacco powder, coal dust, plant fiber dust, and so on, to accurately determine the maximum explosion pressure of the dust cloud, the maximum rate of rise of the explosion pressure, the explosion index, the explosion of the lower limit and the limiting oxygen concentration and other parameters.

Applications

This instrument is used to measure the explosion index of dust or gas mixtures. The instrument uniformly sprays a dust or gas mixture into a confined space, and induces the test object to explode under the stimulation of an adjustable energy ignition source. The instrument measures the explosion index at the moment of explosion, including parameters such as the maximum explosion pressure pmax of dust, the maximum explosion pressure rise rate Kst, the lower explosion limit LEL of dust, the maximum explosion pressure pmax of gas, the maximum explosion pressure rise rate Kg, and the gas explosion limits (LEL and UEL), providing data support for the study of explosion suppression measures.

Standards

ASTM E1226:Standard Test Method for Minimum Ignition Energy of Dust Clouds in Air

ASTM E1515:Standard Test Method for Minimum Ignition Temperature of Dust Clouds by Electrically Heated Surface

EN 14034-1:Determination of Explosion Characteristics of Dust Clouds - Part 1: Determination of the Maximum Explosion Pressure (Pmax) and the Maximum Rate of Pressure Rise ((dp/dt)max) of Dust Clouds

EN 14034-2:Determination of Explosion Characteristics of Dust Clouds - Part 2: Determination of the Limiting Oxygen Concentration (LOC) for Dust Clouds

EN 14034-3:Determination of Explosion Characteristics of Dust Clouds - Part 3: Determination of the Minimum Ignition Energy (MIE) of Dust Clouds

EN 14034-4:Determination of Explosion Characteristics of Dust Clouds - Part 4: Determination of the Minimum Ignition Temperature (MIT) of Dust Clouds

EN ISO/IEC 80079-20-2:Explosive Atmospheres - Part 20-2: Equipment Protection Levels (EPL) - Classification of Equipment for Dust Atmospheres

ISO/IEC 6184/1:Explosive Atmospheres - Equipment for Explosive Gas Atmospheres - Part 1: General Requirements for Construction, Testing and Marking

ISO/IEC 6184/2:Explosive Atmospheres - Equipment for Explosive Gas Atmospheres - Part 2: Test Methods and Data for Determining Ignition Temperatures of Equipment Surfaces

Features

1) Can test dust, gas and the simultaneous existence of solid / gas mixture of the explosion parameters of the system.

2) Built-in international common test standards, can be tested according to standard parameters, can also be customized.

3) With chemical ignition and electrostatic ignition two ways, applicable to different test purposes.

4) The explosion container has a water circulation jacket to realize the constant temperature of the test environment.

5) Input the target concentration value, automatic cleaning, vacuum, and complete the gas distribution according to the requirements.

6) Dust dispersing device can completely disperse the dust into the explosion container.

7) The experiment is carried out automatically without human intervention.

8) Real-time display of time and pressure, the test process is more intuitive.

9) The results include time - pressure curve, providing detailed information on the explosion.

10) Remote control, to ensure the personal safety of experimental personnel.

11) The use of computer control, data analysis capabilities, curve characteristics of accurate judgment.

Technical Parameters

|

Operating Environment |

(5~45)℃, <85%RH |

|

Explosive Vessel |

20L ball with jacket |

|

Vessel Pressure Resistance |

Design pressure 3.0MPa@25℃ |

|

Sphere Material |

Stainless steel 316 |

|

Sphere Operating Temperature |

Maximum temperature 220℃ |

|

Sphere Volume |

20L |

|

Mezzanine Volume |

1.5L |

|

Diffusion Pressure Sensor |

Range (0~3.5)MPa, overload pressure 10.5MPa, |

|

Dispensing Pressure Sensor |

Accuracy ±0.1% FS, working temperature (-40~105)℃ |

|

Explosive Pressure Detection |

Range (0~200)kPa, overload pressure 600.0 kPa, |

|

Explosive Pressure Detection Channels |

Accuracy ±0.1% FS, working temperature (-40~105)℃ |

|

Explosive Temperature Sensor |

Detection range (0~10.0)MPa, resolution 0.001MPa, |

|

Dust Diffusion Vessel |

Accuracy ±0.5%FS, response time<20μs |

|

Powder Spraying Pressure |

2 pcs |

|

Nozzle Type |

Detection range (0~1000)℃, resolution 0.01℃ |

|

Powder Spraying Delay Time |

Capacity 0.6L, pressure resistance 2.5MPa |

|

Ignition Mode |

2.0MPa |

|

Ignition Delay Time |

Bounce back nozzle |

|

Explosive Pressure Data Acquisition |

(30~50)ms |

|

Ignition Control |

Chemical ignition: customer's own |

|

Ignition Head Condition Detection |

Electrostatic ignition: 15kV, 0.5s |

|

Automatic Gas Dispensing |

60ms |

|

Vacuum System |

Maximum collection rate 100 ks/s, recording time 1s |

|

Snap Ring Diameter x Diameter |

Remote wireless ignition support |

|

Viewing Window |

Electrochemical ignition head contact state and fusion state judgment |

|

Interface |

2 air intakes, 1 air inlet; using partial pressure method of gas distribution, with an independent pressure sensor and electromagnetic valves, gas distribution accuracy ±1%. Solenoid valve, gas distribution accuracy ±0.1% |

|

Power |

Rotary vane vacuum pump, equipped with double impact filters to prevent residual substances from clogging and contaminating the pipeline, and easy to replace |

|

Power |

95mm |

|

Dimensions |

150mm |

|

Operating Environment |

Armored glass, 40mm in diameter |

Accessoriess

1. 20L spherical explosion test container (with water circulation jacket to maintain a constant test environment temperature)

2. Dual ignition assembly: chemical igniter and electrostatic igniter (adaptable to different testing needs)

3. Dust sample diffusion device (works with compressed air to achieve uniform dust cloud distribution)

4. Automatic cleaning & vacuum module (for container pretreatment and post-experiment cleaning)

5. Pressure-time curve detection sensor (accurately collects pressure and time data during the explosion process)

6. Gas mixing assembly (enables configuration of gas/gas-solid mixtures at target concentrations)

7. Water circulation jacket connection piping (piping accessories to ensure constant container temperature)

8. Calibration standard dust sample (calibration components adapted to reference standards)

Test Procedures

1. Pre-experiment Preparation: Check the integrity of components such as the explosion container, ignition head, and sensors. Connect the water circulation jacket pipeline to activate the temperature control function.

Install the chemical or electrostatic ignition head according to the test requirements.

2. Sample and Container Pretreatment: Load a quantitative amount of dust sample (e.g., wood flour, coal dust) into the dust diffusion device, connect it to a 20L spherical container, and seal it.

Activate the automatic cleaning & vacuum module to complete container cleaning and vacuuming; if testing a gas-solid system, configure the target concentration gas using the gas distribution component.

3. Parameter Setting: Select the built-in reference standard (e.g., ASTM E1226) or custom parameters on the instrument interface, and input the target dust concentration.

4. Ignition Test: Introduce compressed air to form a uniform dust cloud inside the container.

Start the ignition program and simultaneously collect the pressure-time change curve.

5. Data and Conclusion: The instrument automatically calculates parameters such as the maximum explosion pressure and pressure rise rate.

After the experiment, the automatic cleaning module was activated to clean the container, the device was shut down, and the test data was exported.

Send product request

Other supplier products

| Ink printing proof press device | How it works: Ink printing proof machine is mainly based on the principle of printing reproduction, through the simulation of the press pressure, ... | |

| Ink printing proof press | How it works: Ink printing proof machine is mainly based on the principle of printing reproduction, through the simulation of the press pressure, ... | |

| Button Impact Machine | With the equipment the impact resistance of plastic sew-through flange buttons can be determined that a falling mass of 0.84kg (29.5oz) is released... | |

| Fabric Wrinkle Bending Tester | Overview The Fabric Wrinkle Bending Tester is a specialized instrument used to assess the wrinkle recovery properties of various textile fabrics. ... | |

| Contact heating and cooling tester | Test standard JIS L 1927Textiles-Measurement method of cool touch feeling property GB/T 35263-2017Textiles-Testing and evaluation for cool sensat... |

Same products

| Gas Oxidizing Property Tester | Seller: Standard International Group (HK) Limited | Product Description Conforms to ISO 10156-2010 “Gases and Gas Mixtures Selection of Cylind... | |

| Battery Powder Compaction Density Measurement System | Seller: Standard International Group (HK) Limited | The Battery Powder Compaction Density Measurement System is a precision testing system designed... | |

| Battery Powder resistance tester | Seller: Standard International Group (HK) Limited | The Powder Resistivity Meter is a precision testing system designed to measure electrical resisti... | |

| KES-SESRU surface roughness/friction tester | Seller: Standard International Group (HK) Limited | TheRoughness/Friction Tester analyzes hand movements-particularly, strokes-performed by artisans ... | |

| Air Permeability Tester STD- F8 | Seller: Standard International Group (HK) Limited | The Air Permeability Tester is designed to quickly and accurately measure the breathability and p... |