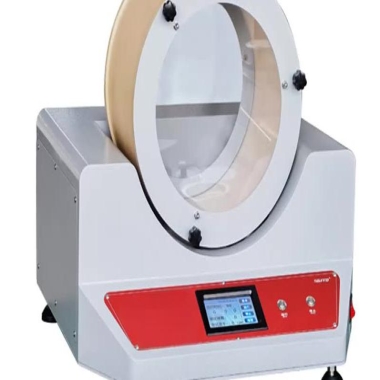

Water Leak Detector

The Water Leak Detector primarily measures the volume and rate of gas released when a substance reacts with water, used to determine the packaging category or hazard level.

Applications

1. Materials Research: In materials science research, water-reactive gas release testers can test the moisture sensitivity and moisture resistance of various materials. This is crucial for developing new materials with excellent moisture resistance, such as building materials and electronic component packaging materials.

2. Chemical Industry: In the chemical industry, water-reactive gas release testers can be used to assess potential side reactions or the release of hazardous substances during chemical reactions. This is essential for ensuring the safety and stability of chemical processes.

3. Oil and Gas Industry: During oil and gas exploration and extraction, there is a risk of toxic or harmful gases being released when underground reservoirs come into contact with high-pressure sulfuric acid brine. Using water-reactive gas release testers for on-site testing allows for the early detection and resolution of potential problems.

4. Environmental Monitoring: Water-reactive gas release testers can also be used for environmental monitoring, particularly for assessing the potential release of pollutants from groundwater and soil. This helps in understanding environmental risks and implementing appropriate remediation measures.

Standards

GB 19521.4-2004:Safety code for inspection of hazardous properties for dangerous good of substances which in contact with water emit flammable gases

NY/T 1860.29-2016 :Guidelines on the determination of physico-chemical properties of pesticides Part 29: Flammability (contact with water)

GB/T 21619-2008:Dangerous goods-Test method for flammable solids, which in contacting with water emit flammable gases

Features

1) Adopting pressure balance method, with high-precision pressure detection and precision motion control, it can effectively collect the gas released by the substance in contact with water, and accurately calculate the release rate and the amount of gas.

2)Simultaneously display the maximum release rate in minutes and hours and the gas collection volume, and draw the rate curve.

3)Traceable instrument calibration function and calibration tools to ensure the accuracy of the instrument.

4)The sample is automatically filled with water under closed conditions to avoid gas leakage during water filling and sample addition.

5)The thermostatic circulation tank and the special metal plate realize the heat and cold conduction to maintain the constant temperature of the test chamber.

6) The gas pipeline is well sealed and has the ability to resist acid and alkali corrosion.

7)With automatic cleaning function of gas line to realize the rapid discharge of residual gas inside the instrument.

8) Configuration of gas collection bag to automatically collect the released gas, in order to analyze the composition of the gas or combustion test

9)The door is equipped with observation window and illumination, which is convenient to observe the reaction state.

10)The accessories can be configured to carry out the water test, stay test and drip test.

11) The test process is fully automated, without human intervention, support for parameter setting, data storage, view reports and other functions, real-time display of the test status, the background automatically save the original data

12) 7-inch LCD touch screen, Chinese intelligent input method, simple and convenient operation

13)Adopting embedded processor and Windows CE operating system, fast, stable and reliable operation.

Technical Parameters

|

Operating Environment |

(5~40)℃, <85%RH |

|

Temperature Control Range of Test Chamber |

(10~35)℃, default temperature control target: 20℃, can be set by software |

|

Temperature Control Stability |

±0.5℃ |

|

Test Water Volume |

400mL, the sample automatically into the water |

|

Sample Cup Volume |

20mL |

|

Gas Collection Volume |

0~800mL |

|

Gas Detection Resolution |

0.01mL |

|

Gas Collection Accuracy |

±0.5mL |

|

Sample Gas Release Rate Range |

0~100L/min/kg |

|

Gas Volume Sampling Interval |

1s |

|

Gas Release Rate Calculation Interval |

1min~1h, can be set by software Timing range 0~240h |

|

Timing Range |

0~240h |

Accessoriess

1. Core Working Components

Sealed Test Chamber: Equipped with an explosion-proof/leak-proof structure, suitable for sealed test environments according to standards such as GB/T 21619. used for sample-water reaction and gas collection.

Sample Fixing Bracket: Stably holds the sample to be tested (e.g., pesticides, hazardous flammable solids), ensuring full contact between the sample and water.

Quantitative Water Addition Device: Supports precise control of the water addition volume (matching the "sample-water ratio" requirement in the standard), achieving quantitative contact between the sample and water.

Gas Monitoring/Collection Components: Includes a gas collection unit (e.g., a gas collection bag) and a gas detection probe, used to capture and monitor the gas released when the sample comes into contact with water.

Control Panel: Integrates switches and a status display screen for setting test parameters (water addition volume, duration) and monitoring the test progress.

Safety Protection Components: Chamber pressure warning device and emergency pressure relief structure, adapting to the safety requirements of dangerous goods testing.

2. Auxiliary Accessories

Sample Preparation: Analytical balance (for accurate sample weighing), sample container (for loading the sample to be tested);

Calibration and Maintenance: Standard water-reactive gas-releasing sample (for calibrating instrument detection accuracy), chamber cleaning brush/special cleaning agent;

Consumables: Gas collection bag (for collecting released gas), connecting tubing (gas outlet channel).

Test Procedures

1. Sample Preparation

Weigh the specified amount of the sample to be tested (e.g., pesticides, hazardous solids) using an analytical balance according to the corresponding standard (e.g., NY/T 1860.29-2016), ensuring the sample is dry and free of lumps.

2. Instrument Preparation

Check the sealing of the test chamber to ensure there are no leaks; calibrate the quantitative water addition device to confirm that the water addition accuracy meets the standard requirements; clean the inside of the chamber to avoid residual substances interfering with the test results.

3. Sample Loading and Sealing

Place the weighed sample on the sample holder and place it into the sealed test chamber; close and lock the chamber to ensure the test environment is completely sealed.

4. Starting the Test

Set the test parameters (e.g., water addition volume, reaction time, determined according to the corresponding standard) through the operation panel; start the quantitative water addition device to add the specified amount of water to the sample, ensuring full contact between the sample and water.

5. Gas Monitoring and Recording

Use the gas monitoring/collection components to record the gases released when the sample comes into contact with water (e.g., gas generation rate, flammability, etc., determined according to standard requirements);

Monitor the test status in real time; if the chamber pressure is abnormal, trigger the emergency pressure relief device.

6. Test Completion

After the test, after the chamber has depressurized and cooled, open the chamber and remove the sample residue;

Clean the inside of the chamber with cleaning tools to complete instrument maintenance;

Export the test data and generate a test report.

Send product request

Other supplier products

| Carpet Peel & Tuft Test device | Product Details For tufted carpets or traditional carpets, an important parameter is the retention performance of their tufts. Poor - quality car... | |

| Helmet Webbing Micro - displacement Abrasion Tester | The helmet webbing micro-displacement wear testing machine is a comprehensive testing instrument used to detect webbing wear conditions, webbing mi... | |

| Carpet Dimensional Stability Tester | Standard ASTM D5417(Standard Test Method for Assessing Carpet Dimensional Stability) ISO 2551(Textile Floor Coverings - Determination of Dimens... | |

| Battery Powder resistivity tester | Standards YS/T 587.6-2006 GB/T 24525-2009 GBT 30835-2014 Product Advantages Unmatched Measurement Flexibility Dual-probe compatibility: Switc... | |

| Finished shoes sole bending tester | Finished shoes sole bending testeris used to test shoe stiffness/rigidity by flex shoe to certain angle by certain force. The shoe bending stiffne... |

Same products

| Full-Body Garment Stress Tester,FZ/T 70015 | Seller: Standard International Group (HK) Limited | TheFull-Body Garment Stress Testeris a precision instrument designed to quantify the pressure exe... | |

| Industrial Dry Cleaning Machine,industrial garment steamer | Seller: Standard International Group (HK) Limited | TheIndustrial Dry Cleaning and Energy-Saving Dryer Machinesare designed for high-performance, rel... | |

| MST Medical Compression Stocking Tester,compression sock tester | Seller: Standard International Group (HK) Limited | The MST Medical Compression Stocking Tester is a professional instrument designed to evaluate the... | |

| MMT Liquid Water Separation Tester,MMT Liquid Water Analysis Tool | Seller: Standard International Group (HK) Limited | Applications Textile Manufacturing:Testing waterproof fabrics for outdoor gear R&D:Developi... | |

| Dental material color stability tester | Seller: Standard International Group (HK) Limited | Application The applications of color stability testers for dental materials are mainly reflecte... |