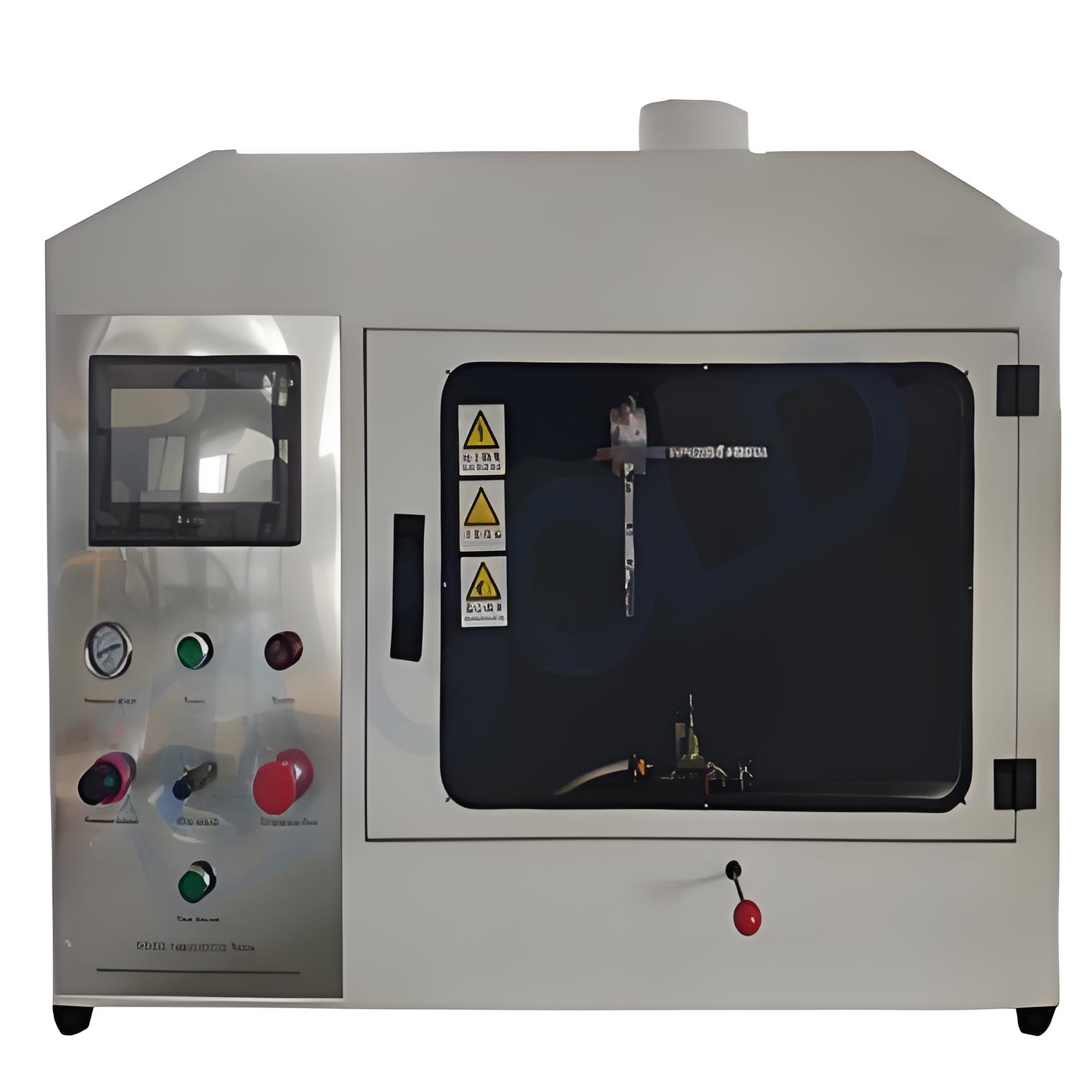

Rubber hose outer coating wear testing machine

The Rubber Hose Outer Coating Wear Testing Machine is a precision laboratory and production testing instrument designed to evaluate the abrasion resistance of rubber and thermoplastic hose outer coatings. It is suitable for hoses reinforced with fabric or steel wire and featuring smooth, flat surfaces. By applying a controlled reciprocating motion with a defined vertical load, this machine simulates real-world wear conditions experienced by hydraulic, automotive, and industrial hoses, providing accurate and reproducible data for quality control, R&D, and material performance evaluation.

Applications

(1) Hydraulic hoses: Rubber hoses with smooth, flat outer coatings reinforced with fabric or steel wire.

(2) Industrial hoses: Air, water, and chemical hoses with similar outer coating structures.

(3) Automotive hoses: Brake lines, fuel lines, and coolant hoses.

(4) Testing laboratories: Quality control and research for abrasion resistance of hose coatings.

(5) Material evaluation: Suitable for rubber, thermoplastic, or composite hose cladding.

Standards

(1) GB/T 12721-2007 — Determination of abrasion resistance of rubber hose outer coating

(2) ISO 6945:1991 — Rubber hoses — Determination of abrasion resistance of cladding

(3) KS M ISO 6945-2013 — Determination of abrasion resistance of the outer coating of rubber hoses

(4) EN ISO 6945-1996 — Determination of abrasion resistance of rubber hose outer coatings

(5) DS/ISO 6945-1984 — Determination of wear resistance of rubber hose cladding

Features

(1) High reproducibility: Provides consistent and accurate abrasion testing of rubber hose outer coatings.

(2) Versatile mandrel sizes: Supports a wide range of shaft diameters to accommodate different hose types.

(3) Adjustable load: Vertical static pressure can be set according to the product standard or customized.

(4) Simulates real-world wear: Reciprocating motion reproduces the friction and wear that hoses experience in operation.

(5) Easy operation and setup: Simple installation of hose samples and abrasive tool ensures quick test preparation.

Technical Parameters

| Item | Specification |

|---|---|

| Reciprocating frequency | 1.25 Hz (45 RPM) |

| Cycle stroke | 200 mm |

| Loading static pressure | 50 N ± 0.5 N (customizable) |

| Mandrel length | 150 mm |

| Shaft diameters | 5, 8, 10, 13, 16, 19, 22, 25, 32, 38, 45, 51 mm (3 selectable, or customized) |

| Power supply | AC 220V, 50/60 Hz (typical) |

Accessories

(1) Main testing machine ×1

(2) Standard mandrels (3 selectable sizes) ×1 set

(3) Abrasive tool ×1

(4) Weights for loading pressure ×1 set

(5) Power cable ×1

(6) Instruction manual ×1

Test Procedure

(1) Install the assembled hose sample and mandrel on the test device, ensuring no axial movement or rotation.

(2) Position the abrasive tool in contact with the sample and apply the vertical static pressure F specified by the standard (or 50 N ± 0.5 N if unspecified).

(3) Start the machine and allow it to run until the required number of cycles is completed.

(4) Remove the sample assembly, clean off any debris or particles from the outer coating, and weigh the sample (with or without core shaft) to compare with initial weight.

Maintenance Information

(1) Regularly clean the abrasive tool and test mandrels to remove rubber debris.

(2) Inspect the reciprocating mechanism and bearings periodically for smooth operation.

(3) Check calibration of applied load weights to ensure consistent static pressure.

(4) Lubricate moving parts according to the manufacturer’s recommendations.

(5) Store the machine in a clean, dry environment when not in use.

Send product request

Other supplier products

| STD Battery short-circuit tester | The Battery Short-Circuit Tester is designed for external short-circuit safety testing of lithium-ion batteries and battery packs. The system simu... | |

| Fiber Blend Ratio meter | Product Introduction: It is used to measure the resistance value with a certain density under a certain geometry, and then converts it into the sp... | |

| Shoelace wear tester丨Shoelace wear test mechine | Main uses: Shoelace wear tester is mainly used to evaluate the durability and wear resistance of shoelaces. In the test, the LACES are usually fix... | |

| Single-Flame Source Tester, ISO11925-2,DIN 53438; DIN4102-1 | Introduction This instrument is designed according to ISO11925-2. it is used to test building material under conditions in the absence of external... | |

| Cork Penetration and Fragment Detection Device | The rubber stopper puncture debris detector is a device specifically used to detect the number of debris generated during the puncture process and ... |

Same products

| Full-Body Garment Stress Tester,FZ/T 70015 | Seller: Standard International Group (HK) Limited | TheFull-Body Garment Stress Testeris a precision instrument designed to quantify the pressure exe... | |

| Industrial Dry Cleaning Machine,industrial garment steamer | Seller: Standard International Group (HK) Limited | TheIndustrial Dry Cleaning and Energy-Saving Dryer Machinesare designed for high-performance, rel... | |

| MST Medical Compression Stocking Tester,compression sock tester | Seller: Standard International Group (HK) Limited | The MST Medical Compression Stocking Tester is a professional instrument designed to evaluate the... | |

| MMT Liquid Water Separation Tester,MMT Liquid Water Analysis Tool | Seller: Standard International Group (HK) Limited | Applications Textile Manufacturing:Testing waterproof fabrics for outdoor gear R&D:Developi... | |

| Dental material color stability tester | Seller: Standard International Group (HK) Limited | Application The applications of color stability testers for dental materials are mainly reflecte... |