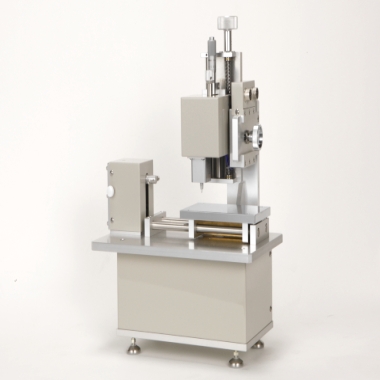

Bag lifting fatigue testing machine

This machine is suitable for up and down vibration fatigue test of plastic handbag, garbage vest bag, kraft paper bag, woven bag and other bags bearing a certain weight. After many fatigue tests, the strength of the bag can be determined. The bag lifting fatigue testing machine adopts the automatic test mode, placing the sample on the fixture, setting the lifting times and load weight, and automatically completing the experiment process and printing the results. This fatigue testing machine is widely used in quality inspection institutions and handbag manufacturers.

Applications

1. Used for fatigue testing of paper and plastic shopping bags.

2. Used for testing the fatigue strength of disposable non-woven shopping bags and related products.

3. Used for fatigue testing of plastic products such as plastic garbage bags and eco-friendly bags.

4. Used for fatigue testing of plastic bags such as supermarket shopping bags and vest-style bags.

Standards

ISO 1167:Thermoplastics pipes, fittings and assemblies for the conveyance of fluids — Determination of the resistance to internal pressure

ASTM D 1598-23:Standard Test Method for Time-to-Failure of Plastic Pipe Under Constant Internal Pressure

ASTM D 1599-18 (2024):Standard Test Method for Resistance to Short-Time Hydraulic Pressure of Plastic Pipe, Tubing, and Fittings

Features

Microcomputer control, large LCD display

Four-column structure, the fatigue test process is stable and reliable

PVC operating panel, humanized design

The number of bag lifting fatigue test can be set freely

Selection of excellent components, low noise, high life

The bag lifting fatigue machine comes with a printer, which can quickly print the experimental results

Bag weight can be set, the experimental results are clear

Technical Parameters

| Parameter | Specification |

|---|---|

| Amplitude | 30±2mm |

| Vibration frequency | ——3HZ (130 times per minute) |

| Test space height | 500/1000mm |

| Load | 20Kg |

| Counting range | 99.999 times in a single cycle |

| Dimensions | 570mm510mm1520mm (length, width and height) |

| Weight | 60KG |

| Power supply | 220V 50Hz |

Accessoriess

Bag fatigue testing machine (main unit), miniature printer

Test Procedures

1. Basic Operating Procedure

1.1 Instrument Installation and Debugging

Place the testing machine on a stable surface and adjust the leveling screws to ensure the equipment is level. When connecting the power cord, confirm that the voltage matches (usually 220V) and check that the aviation connector has good contact.

After starting the equipment, perform a no-load test: set the vibration frequency to 2Hz and observe whether the amplitude is stable within the range of 30mm ± 2mm. If the deviation exceeds ±2mm, adjust the motor parameters or check the transmission components.

1.2 Sample Preparation and Loading

According to standard requirements, select representative samples (such as plastic bags, kraft paper bags) and fill them with a granular mixture equivalent to twice the nominal weight of the contents (such as sand, rice grains). The loading amount should be controlled at 3/4 of the effective volume of the bag to avoid sample deformation due to overfilling.

When suspending the sample from the testing machine's fixture, ensure that the lifting straps are evenly stressed. A spirit level can be used to assist in adjustment to keep the sample vertical during vibration.

1.3 Parameter Setting and Start-up

Enter the equipment operation interface and set the vibration frequency (2Hz to 3Hz), number of cycles (e.g., 1800 cycles), or time (e.g., 10 minutes). Some equipment supports multi-mode switching; you can choose "cycle priority" or "time priority" mode as needed.

Press the "Reset" button and then start the test. The equipment will automatically record the number of vibrations. During the test, the operator should observe the sample status. If the lifting strap breaks or the bag body ruptures, immediately press the "Emergency Stop" button.

2. Key Parameter Settings

2.1 Amplitude and Frequency Control

According to the GB/T 38082-2019 standard, the amplitude must be strictly controlled at 30mm ± 2mm, and the frequency should be 2Hz to 3Hz (130 cycles per minute). A study shows that a frequency deviation of 0.5Hz can lead to an error of more than 10% in the 3600-cycle test time, directly affecting fatigue life assessment. Some equipment supports dynamic adjustment functions, allowing for fine-tuning of parameters during the testing process based on the deformation of the sample. For example, when testing biodegradable plastic bags, if the elongation of the handle exceeds 5%, the frequency can be reduced to 1.8 Hz to prevent premature breakage.

2.2 Load and Cycle Settings

The load setting should be based on the nominal load capacity of the sample. For example, when testing shopping bags with a nominal load capacity of 5 kg, 10 kg of granular mixture should be loaded. The number of cycles should be set according to standard requirements: GB/T 38082 specifies 1800 cycles as the passing threshold, while internal company standards may increase this to 3600 cycles.

Send product request

Other supplier products

| Fully Automatic Continuous Flow Reaction Calorimeter | This product is a highly automated and customizable continuous flow reaction thermal analysis and calorimetry platform. It features automatic sampl... | |

| Torsional Fatigue Tester | Standard YY/T 0857-2011 (China): Specifies torsional fatigue testing protocols for spinal pedicle screw-rod systems, including load ratios, freque... | |

| Digital display electronic ink viscosity meter | Standard: ISO 12644 Functional features: Intelligent design: The use of advanced intelligent control system, can clearly and accurately display ... | |

| Standard Helmet Visual Field Tester | Standards EN 1078:2023: Helmets for Pedal Cyclists, Skateboarders, and Roller Skaters CE Certification(Conformité Européenne) Equi... | |

| Suitcases Vibration Impact Tester | This machine is used to test the shock resistance of various luggage handles, car stitches and overall structure. The method is to load the specifi... |

Same products

| Gas Oxidizing Property Tester | Seller: Standard International Group (HK) Limited | Product Description Conforms to ISO 10156-2010 “Gases and Gas Mixtures Selection of Cylind... | |

| Battery Powder Compaction Density Measurement System | Seller: Standard International Group (HK) Limited | The Battery Powder Compaction Density Measurement System is a precision testing system designed... | |

| Battery Powder resistance tester | Seller: Standard International Group (HK) Limited | The Powder Resistivity Meter is a precision testing system designed to measure electrical resisti... | |

| KES-SESRU surface roughness/friction tester | Seller: Standard International Group (HK) Limited | TheRoughness/Friction Tester analyzes hand movements-particularly, strokes-performed by artisans ... | |

| Air Permeability Tester STD- F8 | Seller: Standard International Group (HK) Limited | The Air Permeability Tester is designed to quickly and accurately measure the breathability and p... |